Solid carbon source as well as preparation method and application thereof

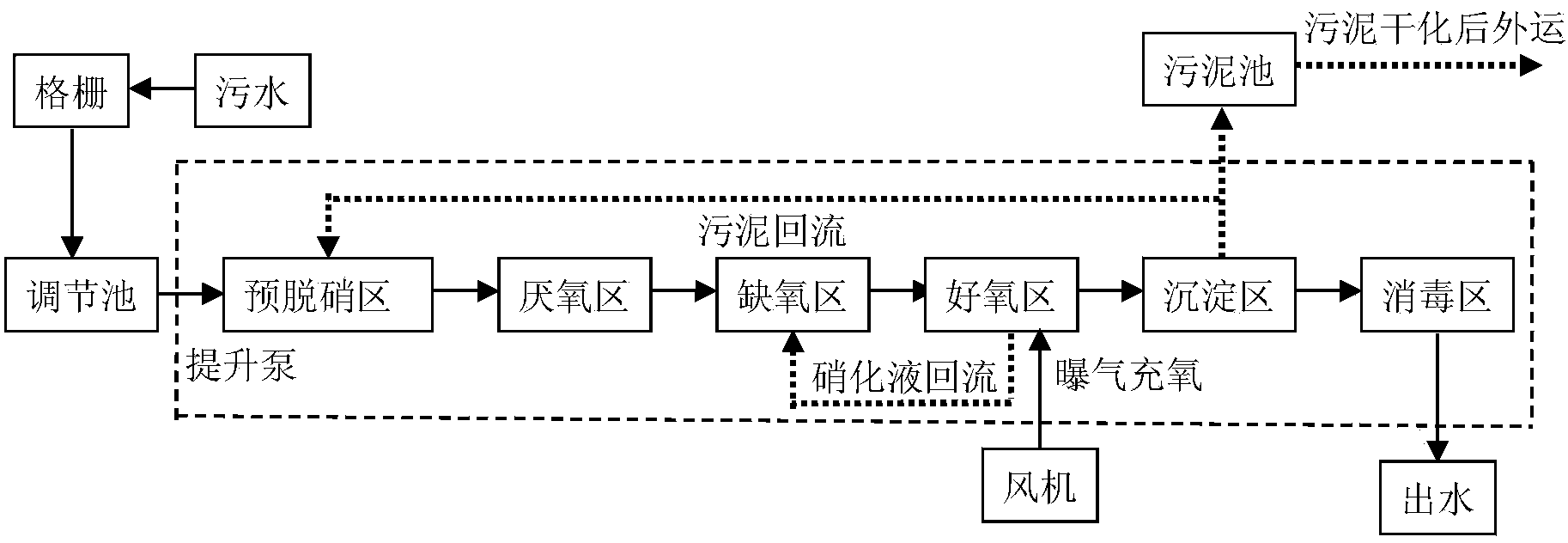

A solid carbon source and sewage treatment method technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of low nitrogen removal efficiency, slow release speed, carbon source Insufficient and other problems, to achieve the effect of reducing the cost of sewage treatment, high utilization rate, and long-term stable carbon source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-16

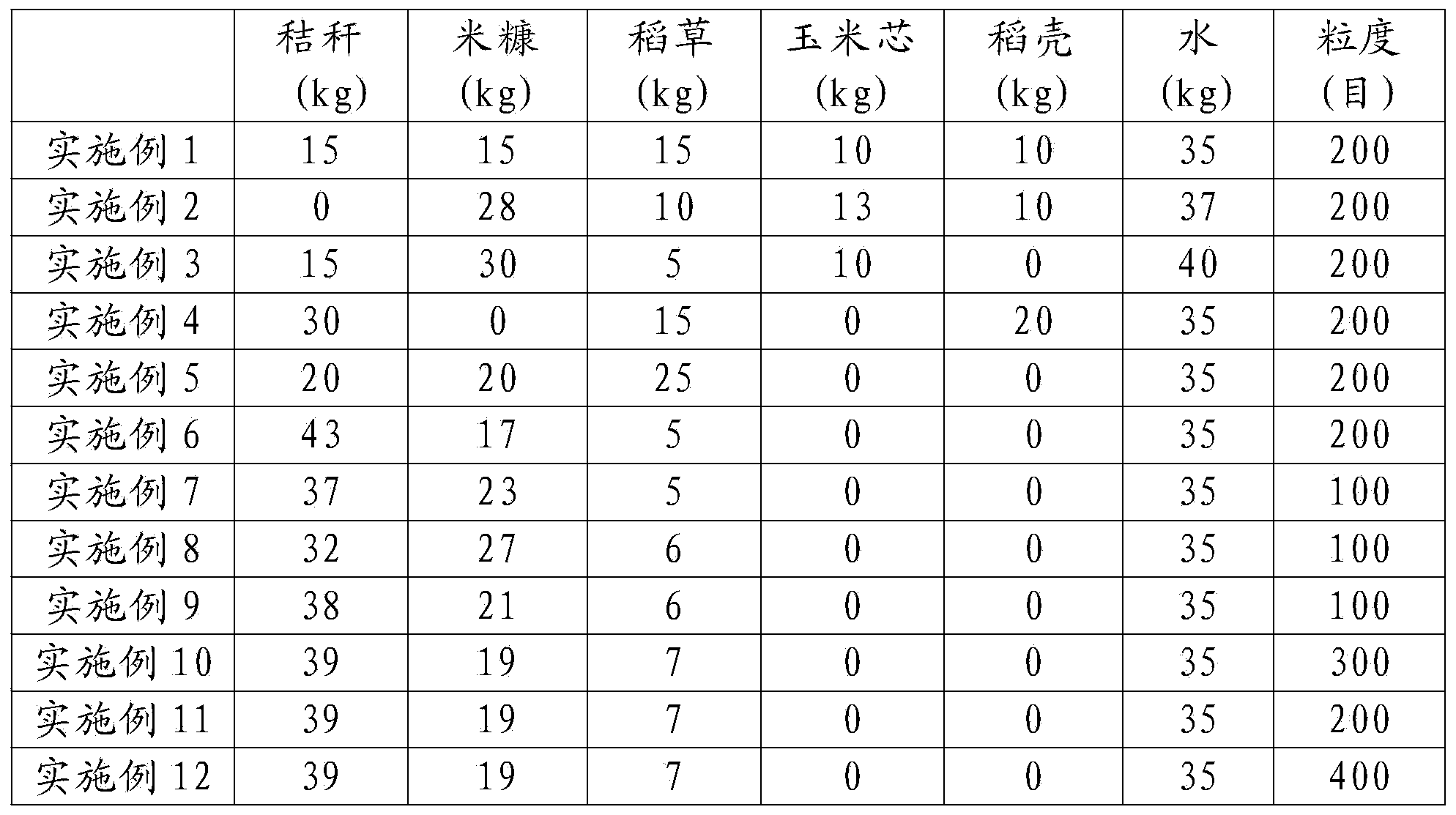

[0026] Embodiment 1-16 solid carbon source and preparation

[0027] (1) Collect cellulose-rich substances, such as rice husks, corn cobs, straw, rice straw, and rice bran, etc., and then crush them to 400 mesh or below to form powders for later use.

[0028] (2) Weighing each powder substance and water for making solid carbon source respectively, the amount of water is 35-45% of the total mass of each powder substance, and then mixing them uniformly to obtain a mixture. The amount of each substance used is shown in Table 1 below.

[0029] (3) Send the mixture into a granulator for granulation (with a particle size of 10-15 mm) and preliminary drying to obtain pellets; the drying temperature is 70-80° C., and the drying time is 50-70 minutes.

[0030] (4) Put the pellets into an oven at 105-110° C. and bake for 1.5-2.5 hours to obtain raw pellets.

[0031] (5) Preheat the raw meal balls in a rotary kiln at 300-500°C for 30 minutes, then gradually increase the temperature of t...

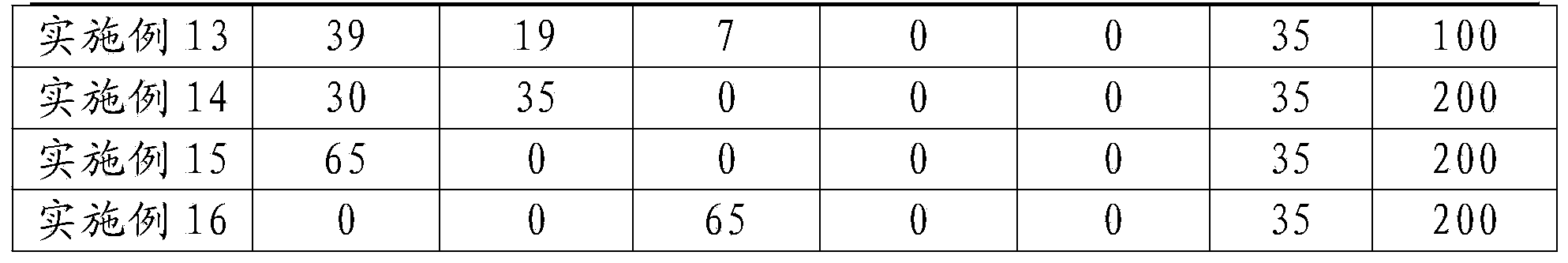

Embodiment 17

[0036]The amount of each substance used to prepare the solid carbon source in this example is the same as that in Example 11, that is, 39 kg of straw powder, 19 kg of rice bran powder, and 7 kg of rice straw powder. The preparation method of the solid carbon source is different from that in Example 11, and the straw powder, rice bran powder and rice straw powder are uniformly mixed. The uniformly mixed solid carbon source can also be packed into a mesh bag for subsequent use in sewage treatment.

[0037] The sieve particle size of different sizes is tested by the sieving method, and the specific surface area is determined by the BET specific surface area detection method. The specific surface area of each carbon source material used to prepare the solid carbon source affects the release rate of the solid carbon source, and the particle size is small. The specific surface area of the carbon source material is greater than that of the carbon source material with a large part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com