An improved multi-stage a/o denitrification system with multi-stage water inlet

A staged water inlet and improved technology, applied in the direction of aerobic and anaerobic process treatment, to achieve the effect of reducing manual management and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

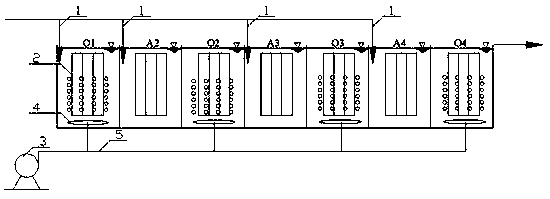

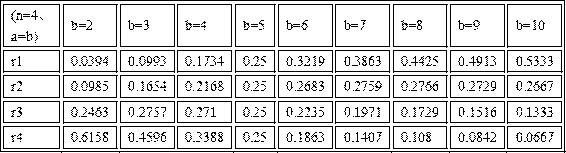

[0020] In this example, the rural domestic sewage is taken as the research object, and the experimental research work is carried out on the biological denitrification technology of sub-influential water. The operating parameters of the process are: four-stage improved multi-stage A / O process with water inflow, the total effective volume of the reactor is 69L, and the COD of water inflow Cr =210mg / L, TKN=40mg / L, hydraulic retention time is 13h. According to the influent water quality, the value of a is 5, and the distribution of influent flow at all levels is calculated as: 38.6%, 27.6%, 19.7% and 14.1%, respectively, and the volume of each aerobic pool is calculated according to the principle of equal ammonia nitrogen volume load based on the distribution coefficient , the volume ratio of anoxic pool to aerobic pool is 1:1.

[0021] The reaction system is started by inoculating sludge to form a film. The inoculating sludge can be selected from the sludge in the secondary sedi...

Embodiment 2

[0024] This example is a demonstration project of domestic sewage treatment in a rural area, and its influent COD is actually measured Cr 200mg / L, NH 4 + -N is 25mg / L, and the average value of TN is about 30mg / L. It is required that the effluent TN≤12mg / L after treatment, and the four-stage improved segmented water inlet design is adopted, that is, "O / A / O / A / O / A / O" four-stage process, the value of a is 7, and the water flow distribution of each level is: 23.5%, 24.5%, 25.5%, and 26.5%.

Embodiment 3

[0026] A rural domestic sewage treatment demonstration project in Xiamen City adopts the "O / A / O improved segmented water inflow + ecological wetland" technology, and the influent COD Cr The average TN is 130mg / L, and the average TN is 30mg / L. The average removal rate of TN in the effluent is 60% after the improved staged influent denitrification treatment, and the effluent treated by the ecological wetland can stably reach the DB-35-322-1999 "Xiamen City Water Pollutants According to the first-level standard of the Emission Control Standard, the power consumption per ton of water in the facility is 0.2kwh, and the treatment cost per ton of water is 0.16 yuan. The equipment of the system is easy to operate, with low failure rate and low maintenance cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com