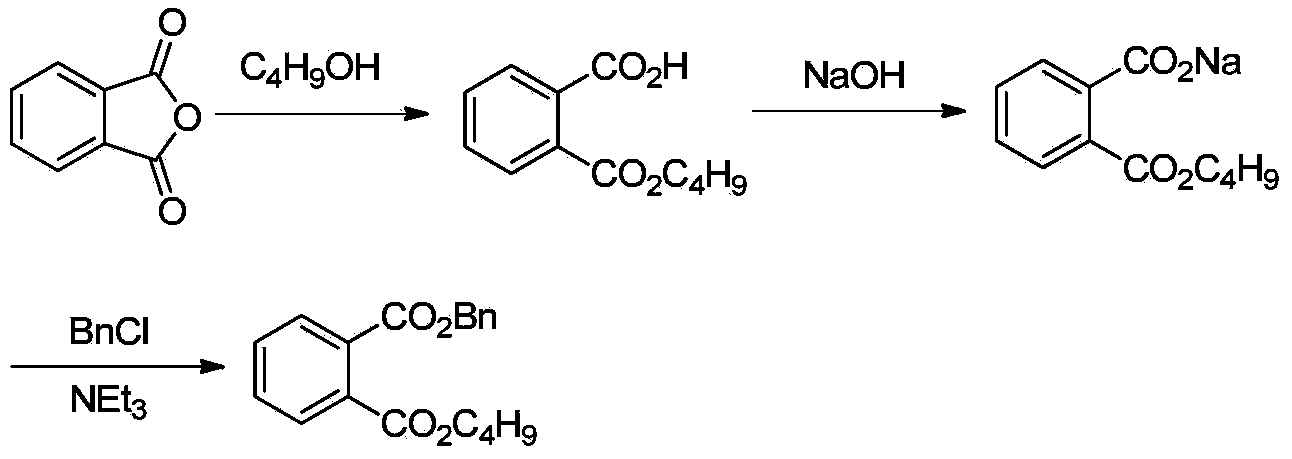

Method for preparing benzyl acetate by using butyl benzyl phthalate rectified low-boiling-point substances

A technology of butyl benzyl phthalate and benzyl acetate, which is applied in the field of preparing benzyl acetate, can solve problems such as inability to separate, waste resources, and large economic losses, and achieve the effects of contributing to environmental protection, saving resources, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

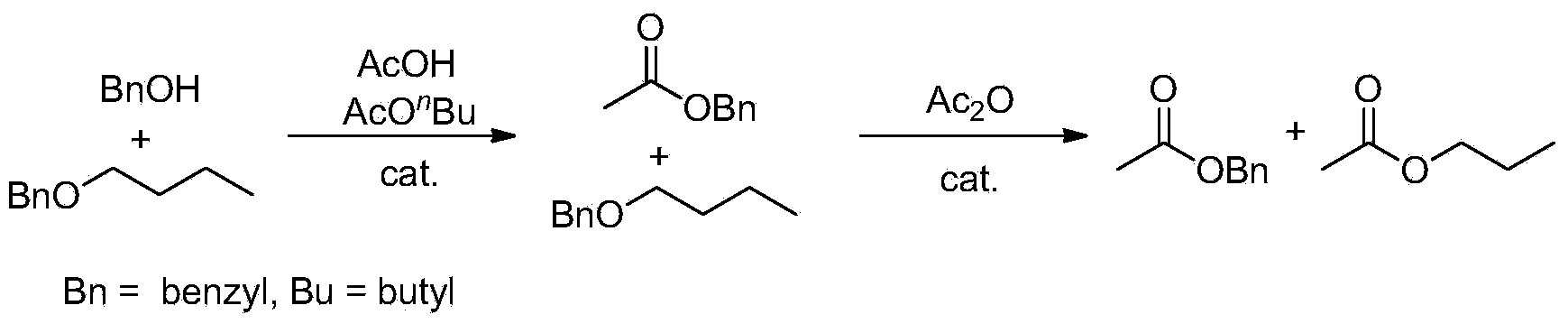

[0025] A kind of method that utilizes butyl benzyl phthalate rectification low boiler to prepare benzyl acetate comprises the following steps:

[0026] 1) In a 100mL three-necked flask, add 300g of butyl benzyl phthalate rectification low boiler, 200g of acetic acid (98% purity), 30mL toluene (98% purity) and 1.5g sulfamic acid (95% purity) After testing, benzyl alcohol content is 80% (GC, area %), benzyl butyl ether content is 20% (GC) in this phthalate butyl benzyl ester rectification low boiler, heat up to 110°C azeotropic reflux reaction and water separation;

[0027] 2) When there is no obvious water in the phase separator, add 73g acetic anhydride (98% purity) and 1.5g sulfamic acid (95% purity) to the reactor, and heat up to 140-150°C to continue the reaction. Use gas chromatography to monitor the reaction process. When the residual benzyl butyl ether component content in the system is lower than 0.2% (GC, area %), you can stop heating and cool down;

[0028] 3) The p...

Embodiment 2

[0030] A kind of method that utilizes butyl benzyl phthalate rectification low boiler to prepare benzyl acetate comprises the following steps:

[0031] 1) Add 120kg butyl benzyl phthalate rectification low boiler (component is the same as embodiment 1), 72kg glacial acetic acid, 1.5kg p-toluenesulfonic acid (purity 95%), 30kg butyl acetate in 300L reactor (purity 98%), heating the reactor to 110°C for azeotropic reflux and water separation;

[0032] 2) When there is no obvious water in the phase separator, add 35kg of acetic anhydride and 1.5kg of p-toluenesulfonic acid to the reactor, and heat up to 150°C to continue the reaction. During the reaction, use gas chromatography to monitor the reaction process. When the system When the remaining benzyl butyl ether component content is lower than 0.2% (GC), the heating can be stopped and cooled;

[0033] 3) The product obtained by the reaction is distilled under reduced pressure to remove remaining acetic acid, acetic anhydride an...

Embodiment 3

[0035] A kind of method that utilizes butyl benzyl phthalate rectification low boiler to prepare benzyl acetate comprises the following steps:

[0036] 1) Add 120kg butyl benzyl phthalate rectification low boiler (component is the same as embodiment 1), 70kg glacial acetic acid, 1.5kg sulfamic acid, 30kg butyl acetate in the 300L reactor, heat up the reactor Azeotropic reflux at 110°C for water separation;

[0037] 2) When there is no obvious water in the phase separator, add 35kg of acetic anhydride and 1.5kg of p-toluenesulfonic acid to the reactor, and heat up to 160°C for reaction. During the reaction, use gas chromatography to monitor the reaction process. When the benzyl butyl ether component content is lower than 0.2% (GC), the heating can be stopped and cooled;

[0038] 3) The product obtained by the reaction is distilled under reduced pressure to remove low boilers such as acetic acid, acetic anhydride and butyl acetate remaining in the crude product, and the resulti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com