Novel temperature-sensitive polymer and method for preparing novel temperature-sensitive polymer from L-lysine as renewable resource

A technology for temperature-sensitive polymers and renewable resources, which is applied in the field of polymers and can solve problems such as preparation and non-existence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Preparation of L-lysine methyl ester dihydrochloride

[0058] Dry the 500ml single-necked flask, add 36.5gL-lysine monohydrochloride, add 500ml methanol, and add 45ml of benzoyl chloride dropwise under ice-water bath conditions. After the dropwise addition, continue the reaction at room temperature for 45 minutes, then placed in a 70°C oil bath and heated to reflux for 3 hours, then cooled at room temperature overnight, crystals precipitated, filtered, washed with ether, and dried in vacuum at 20°C for 12 hours to obtain L-lysine methyl ester dihydrochloride 29.2g, yield 80%.

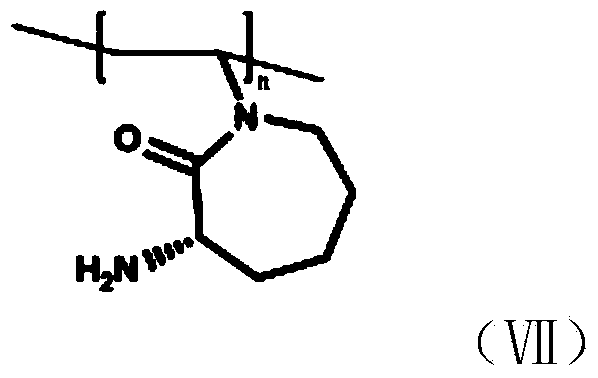

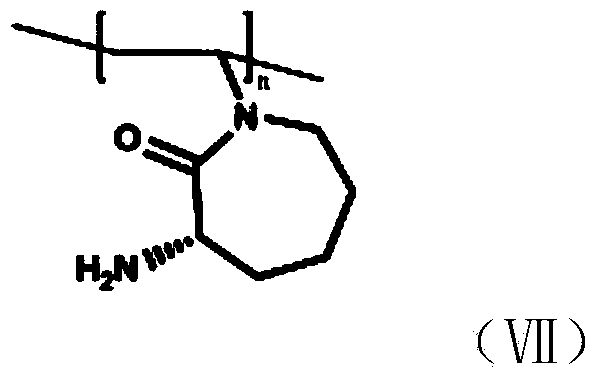

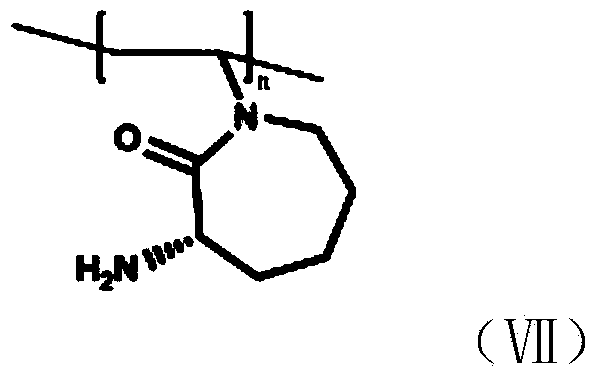

[0059] Preparation of (S)-α-aminocaprolactam

[0060] Dry the 500ml three-necked flask, weigh 23.3g L-lysine methyl ester dihydrochloride, dissolve it in 320ml methanol, add dropwise 80mL methanol solution containing 10g sodium hydroxide at room temperature, react at room temperature for 24h, filter, spin The filtrate was dried and recrystallized to obtain 18.6 g of (S)-α-aminocaprolactam as a ...

Embodiment 2

[0071] Preparation of L-lysine methyl ester dihydrochloride

[0072] Dry the 500ml single-necked flask, add 36.5gL-lysine monohydrochloride, add 500ml of methanol, and add 43ml of thionyl chloride dropwise under ice-water bath conditions. After the dropwise addition, continue the reaction at room temperature for 30 Minutes, then placed in a 70°C oil bath and heated to reflux for 24 hours, then cooled at room temperature overnight, crystals precipitated, filtered, washed with ether, and vacuum-dried at 20°C for 12 hours to obtain L-lysine methyl ester dihydrochloride 33.6 g, yield 92%.

[0073] Preparation of (S)-α-aminocaprolactam

[0074] Dry the 500ml three-necked flask, weigh 23.3g L-lysine methyl ester dihydrochloride, dissolve it in 320ml methanol, add dropwise 80mL methanol solution containing 10g sodium hydroxide at room temperature, react at room temperature for 24h, filter, spin The filtrate was dried and recrystallized to obtain 18.2 g of (S)-α-aminocaprolactam as a ...

Embodiment 3

[0085] Preparation of L-lysine methyl ester dihydrochloride

[0086] Dry the 500ml single-necked flask, add 36.5gL-lysine monohydrochloride, add 500ml methanol, and add 42.8ml sulfonyl chloride dropwise under ice-water bath conditions. After the dropwise addition is completed, continue the reaction at room temperature for 30 minutes. Then placed in an oil bath at 100°C and heated to reflux for 3 hours, the system became clear and transparent, then cooled at room temperature overnight, crystals precipitated, filtered, washed with ether, and dried in vacuum at 20°C for 12 hours to obtain L-lysine methyl Ester dihydrochloride 31.8g, yield 87%.

[0087] Preparation of (S)-α-aminocaprolactam

[0088] Dry the 500ml three-neck flask, weigh 23.3g of L-lysine methyl ester dihydrochloride, dissolve it in 320ml of methanol, add 19mL of dry pyridine dropwise at room temperature, react at room temperature for 6h, filter, spin the filtrate, and recrystallize After that, 14 g of (S)-α-amin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com