Method for preparing coal-based high aromatic potential content raw oil

A high aromatics and raw material oil technology, applied in the field of coal chemical industry, can solve the problems of low added value, difficult to support the development and restriction of downstream PTA and polyester, and achieve the effect of high raw material utilization rate, wide application range of raw materials, and broaden the source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

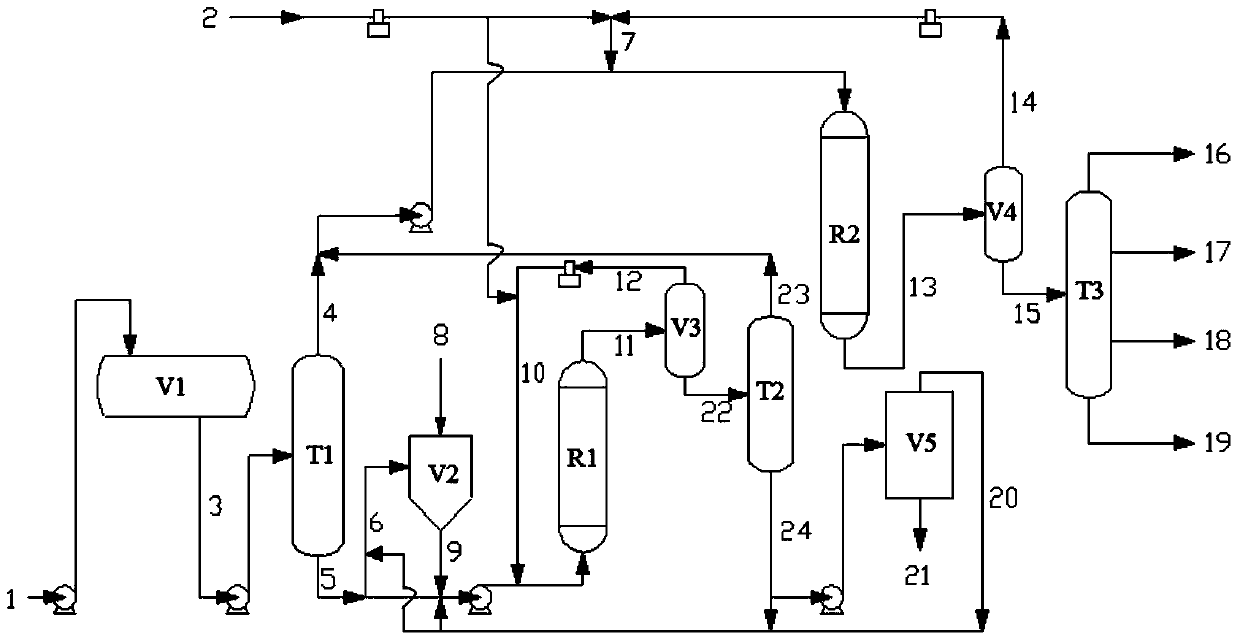

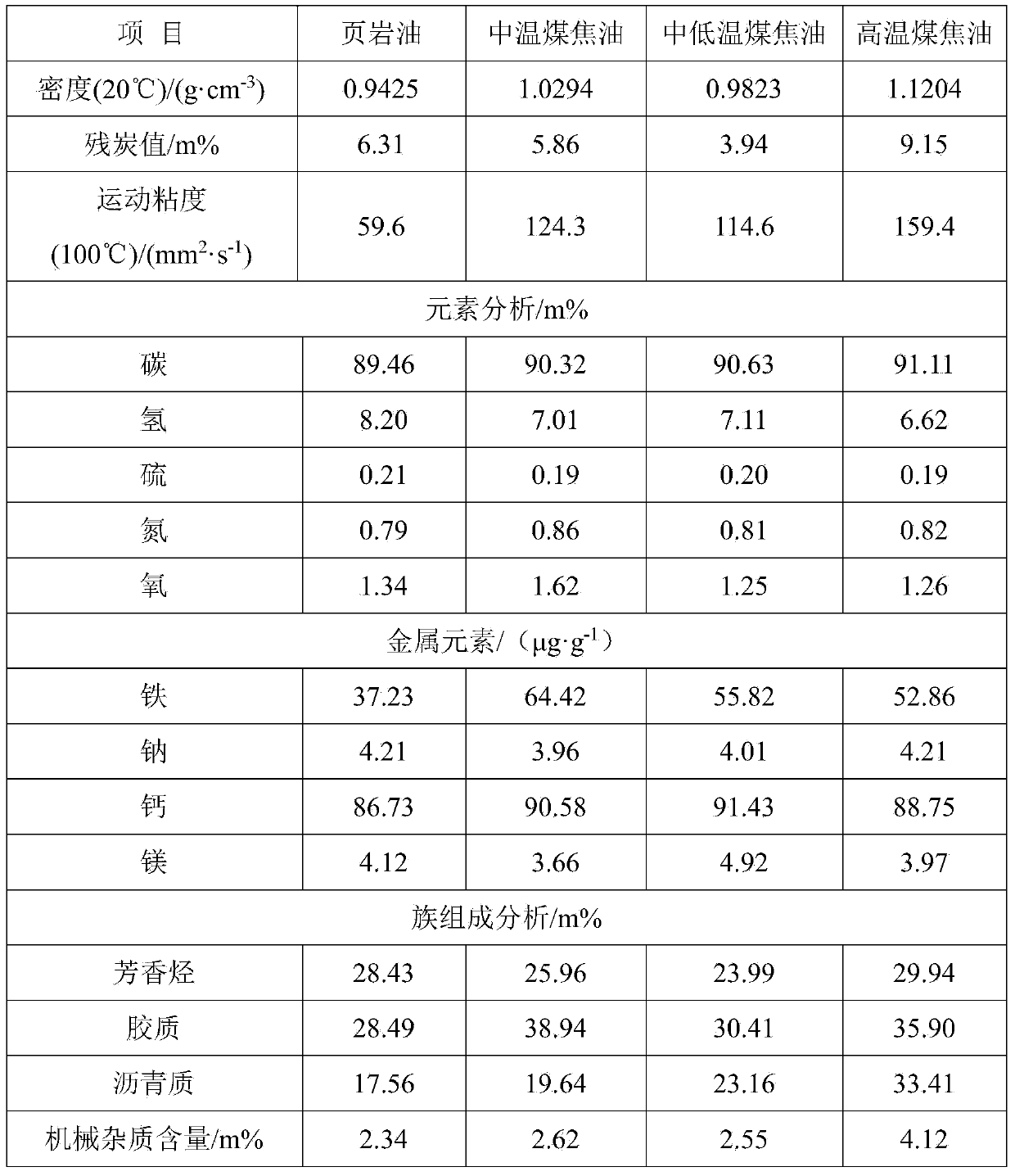

[0065] use figure 1 The technological process of using a shale oil as a raw material, after pretreatment, the pretreated shale oil is distilled and cut by normal pressure distillation or vacuum distillation. The cutting temperature is 370℃, and the cutting temperature is less than 370℃. Light distillate oil and heavy distillate oil above 370°C, and heavy distillate oil above 370°C are feedstock oils for suspended bed hydrocracking. The properties of shale oil full-distillate feedstock oils are shown in Table 1. Heavy distillate oil after hydrocracking light oil and light distillate separated by shale oil distillation can obtain 65~145℃ distillate after hydro-upgrading, that is, the catalytic reforming feedstock oil with high aromatic potential content , The main properties are shown in Table 3. The main process conditions of each process unit are shown in Table 2.

[0066] The vulcanizing agent in this embodiment is sulfur, and the solid concentration in the catalyst slurry is 3...

Embodiment 2

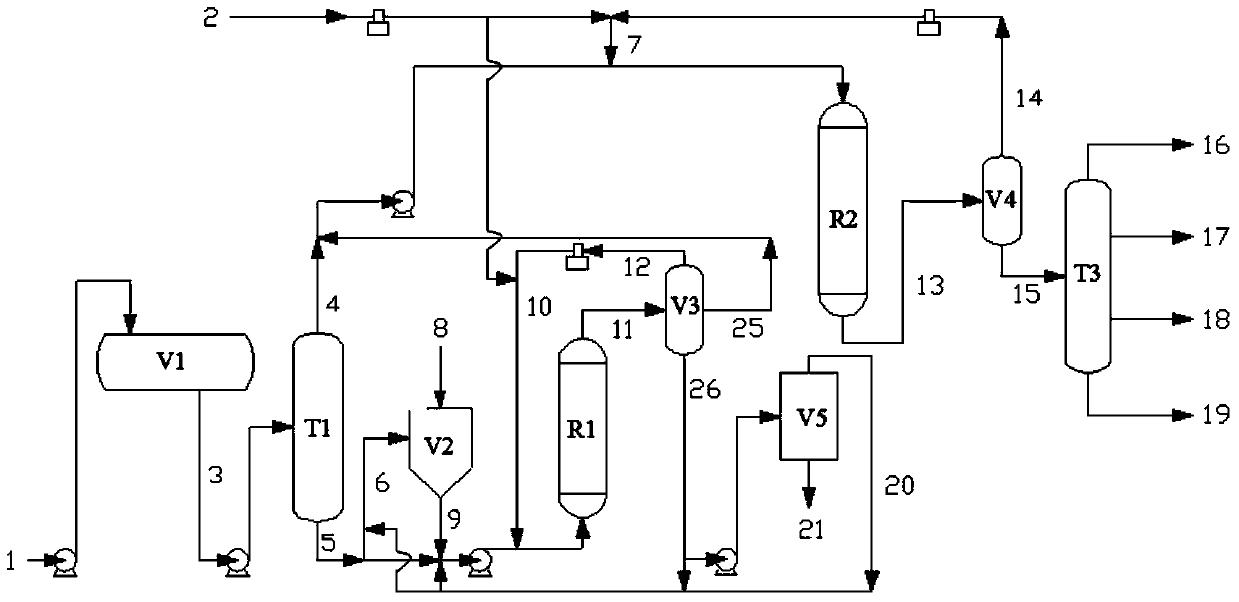

[0069] use figure 2 The process flow of the company uses a medium-temperature coal tar as a raw material. After pretreatment, the pre-treated medium-temperature coal tar is cut under normal pressure distillation. The cutting temperature is 350℃. After cutting, it is divided into light distillate and light distillate less than 350℃. The heavy distillate oil above 350℃ and the heavy distillate oil above 350℃ are feedstock oils for suspended bed hydrocracking. The properties of medium temperature coal tar full distillate feedstock oils are shown in Table 1. After the heavy distillate is hydrocracked, the low-temperature separator oil and the light distillate separated by the coal tar distillation can obtain the 65-150℃ distillate, which is the catalytic reforming feedstock oil with high aromatic content. See Table 3 for properties. The main process conditions of each process unit are shown in Table 2.

[0070] The vulcanizing agent in this embodiment is dimethyl disulfide, and the...

Embodiment 3

[0073] use figure 1 The technological process of the company uses a medium and low temperature coal tar as a raw material. After pretreatment, the pretreated medium and low temperature coal tar is cut by distillation. The cutting temperature is 370°C. After cutting, it is divided into light distillate and light distillate less than 370°C. The heavy distillate oil above 370°C, of which the heavy distillate oil above 370°C is the feedstock oil of the feedstock for suspended bed hydrocracking. The properties of the medium and low temperature coal tar full-distillate feedstock oil are shown in Table 1. After the heavy distillate is hydrocracked, the light oil fraction and the light distillate separated by coal tar distillation can be hydrorefined to obtain a naphtha fraction below 145°C, that is, the catalytic reforming of high aromatic potential content The main properties of raw oil are shown in Table 3. The main process conditions of each process unit are shown in Table 2.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com