Production method of polyphenol-containing choerospondias axillaris juice beverage

A technology of Nansuanjujube juice and a production method, which is applied in the field of beverage processing, can solve the problems of reduced juice viscosity and lack of fullness, and achieve the effects of fullness, retention of taste, and convenience for filtration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

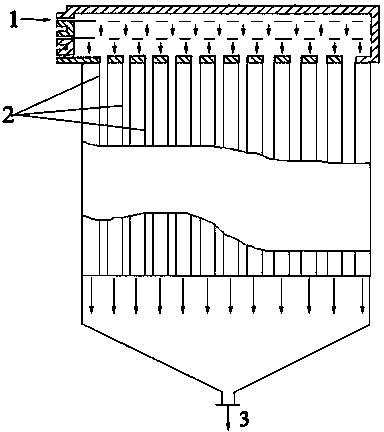

Image

Examples

Embodiment 1

[0021] (1) Select ripe jujube fruit, remove impurities and wash away the sediment; then blanch in hot water at 80°C to kill enzymes; then pour the jujube into a drum-type worm crusher for crushing, so that the pulp and skin are The cores are separated to obtain the fruit core, peel, and fruit pulp of Suanzi jujube respectively.

[0022] (2) Add 40 kg of water to 10 kg of wild jujube pulp, mix well, and then add 0.03 kg of pectinase compound (pectin methylesterase, rhamnogalacturonan hydrolase, arabinan The mass ratio of enzyme and galactanase is 1:1:5:4), the enzymolysis was carried out at 45°C, and after 100 min of enzymolysis, the enzymolysis solution was deenzyme treated at 80°C for 5 min. Centrifuge at 2000 rpm for 15 min in a three-legged centrifuge to obtain the clarified juice of Jujube jujuba.

[0023] (3) Boil 50 kg of water, add 25 kg of white sugar, continue to boil for 5 minutes, and then filter through 200-mesh gauze to obtain sugar solution.

[0024] (4) Use a ...

Embodiment 2

[0030] (1) Select ripe jujube fruit, remove impurities and wash away the sediment; then blanch in hot water at 80°C to kill enzymes; then pour the jujube into a drum-type worm crusher for crushing, so that the pulp and skin are The cores are separated to obtain the southern jujube pulp and the southern jujube fruit core respectively.

[0031] (2) Add 80 kg of water to 20 kg of jujube pulp, mix well, and then add 0.05 kg of pectinase compound (pectin methylesterase, rhamnogalacturonan hydrolase, arabinan The mass ratio of enzyme and galactanase is 1:2.5:3:2), the enzymolysis was carried out at 45°C, and after 100 min of enzymolysis, the enzymolysis solution was deenzyme treated at 90°C for 5 min. Centrifuge at 2000 rpm for 15 min in a three-legged centrifuge to obtain the clarified juice of Jujube jujuba.

[0032] (3) Boil 100 kg of water, add 50 kg of white sugar, continue to boil for 5 minutes, and then filter through 200-mesh gauze to obtain sugar solution.

[0033] (4) Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com