Adsorbent for removing pentavalent inorganic arsenic in water and application method thereof

An application method and adsorbent technology, which are applied to the adsorbent for removing pentavalent inorganic arsenic in water and its application field, can solve the problems of activated carbon accumulation adsorption and adsorption capacity, limited treatment efficiency and practical promotion and application, and uneven distribution of metal oxide deposition Uniformity and other issues, to achieve the effect of improving arsenic removal efficiency, convenient operation and maintenance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

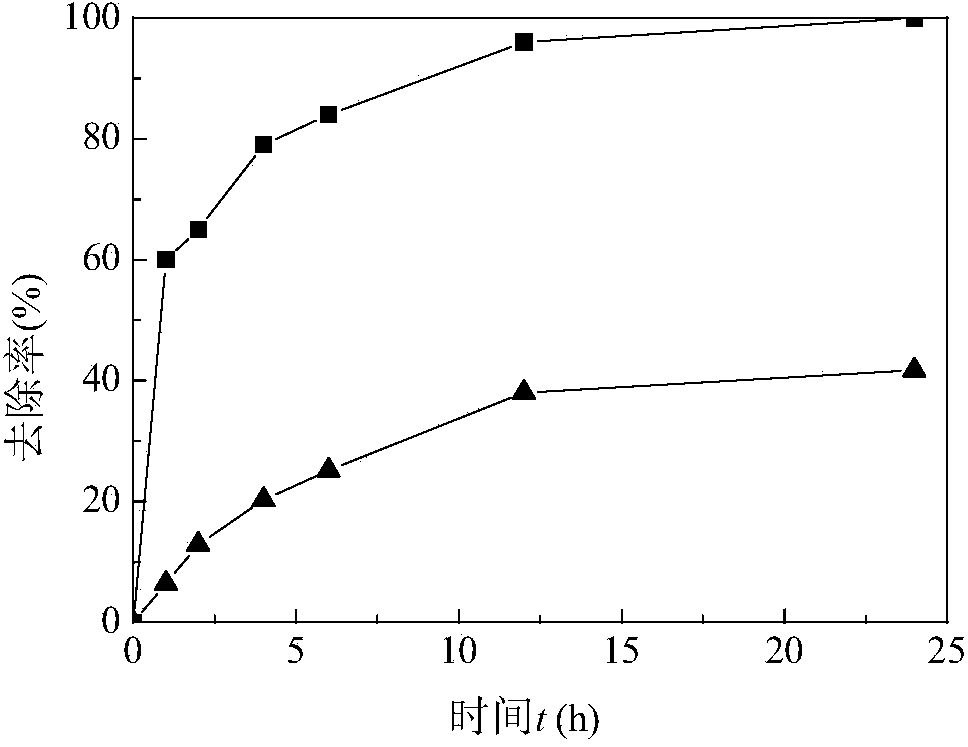

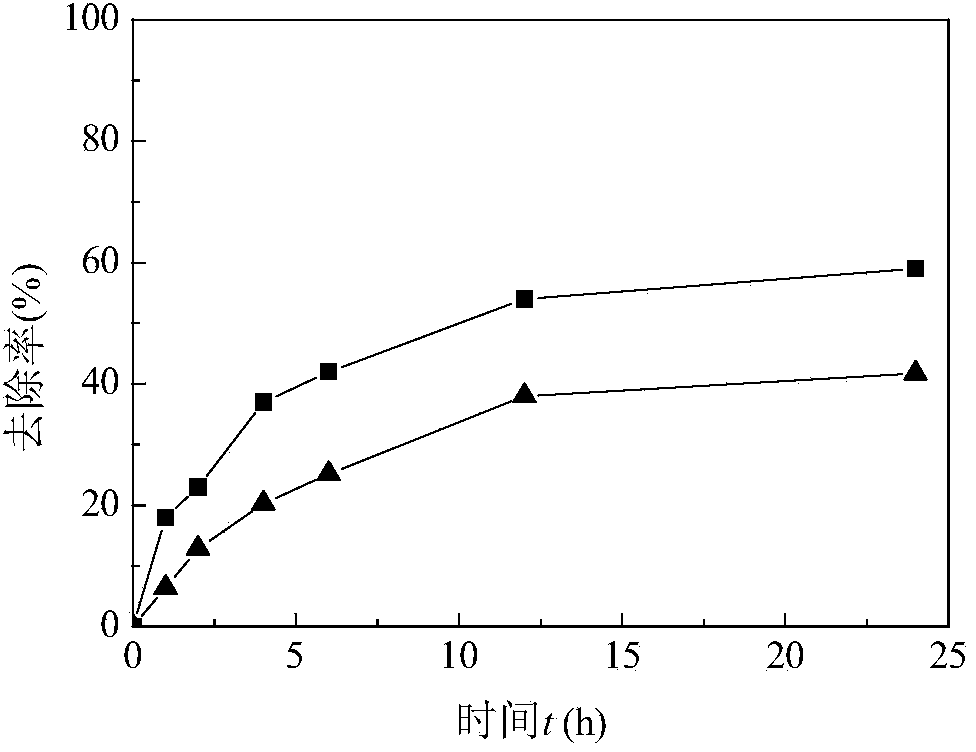

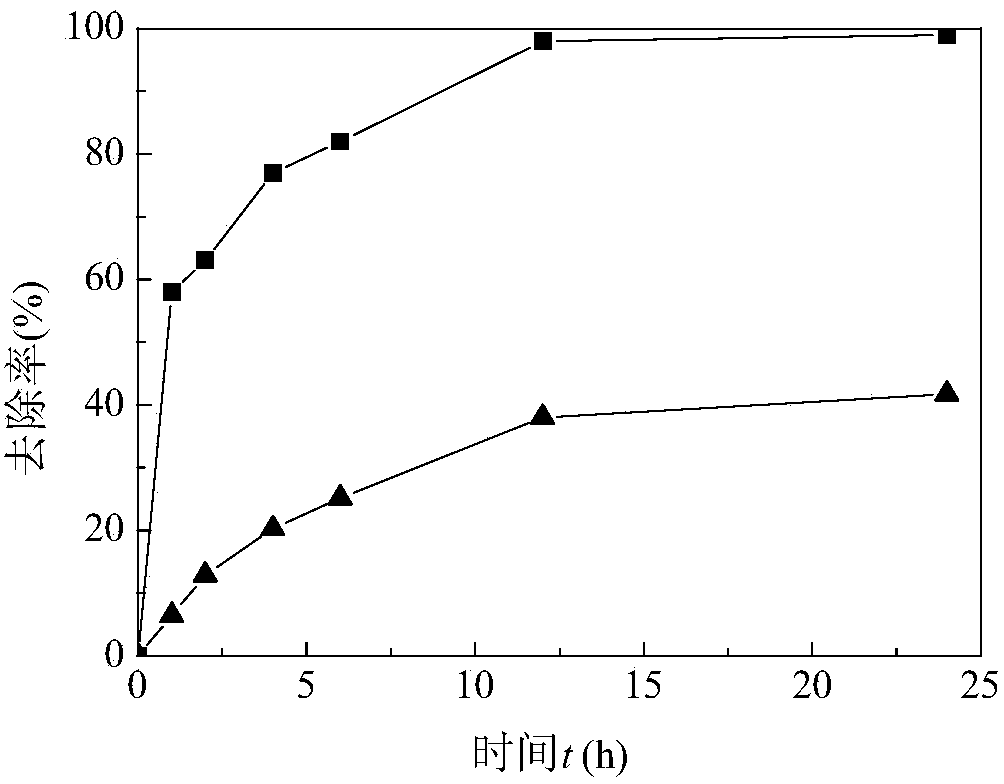

[0026] The preparation method of an adsorbent for removing As(V) in water involved in the invention is simple, and it only needs to measure a certain amount of carbide material and ferrous salt respectively, wherein the quality of carbide material is the same as that of Fe in ferrous salt. 2+ The mass ratio of the mixture is 20:1~1600:1, just mix the two thoroughly and let it stand. Here, activated carbon is used as the carbide material and ferrous chloride is used as the ferrous salt to describe the preparation process in detail.

[0027] Method 1: Taking 100g of finished adsorbent as an example, measure 89.8156g of activated carbon and 10.1844g of ferrous chloride. 2+ The mass ratio of the two is 20:1; mix the two, fully stir for 10-30 minutes; stand and filter to obtain the adsorbent 1 that can adsorb and remove As(V) in water.

[0028] Method 2: Taking 100g of finished adsorbent as an example, measure 99.8585g of activated carbon and 0.1415g of ferrous chloride. 2+ The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com