Optical film and method of manufacturing the same

An optical film and manufacturing method technology, applied in optics, optical elements, optical elements, etc., can solve the problem of inability to obtain polarization degree, etc., and achieve the effect of preventing black belt failure or film deformation failure, and preventing roll deviation or roll loose.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

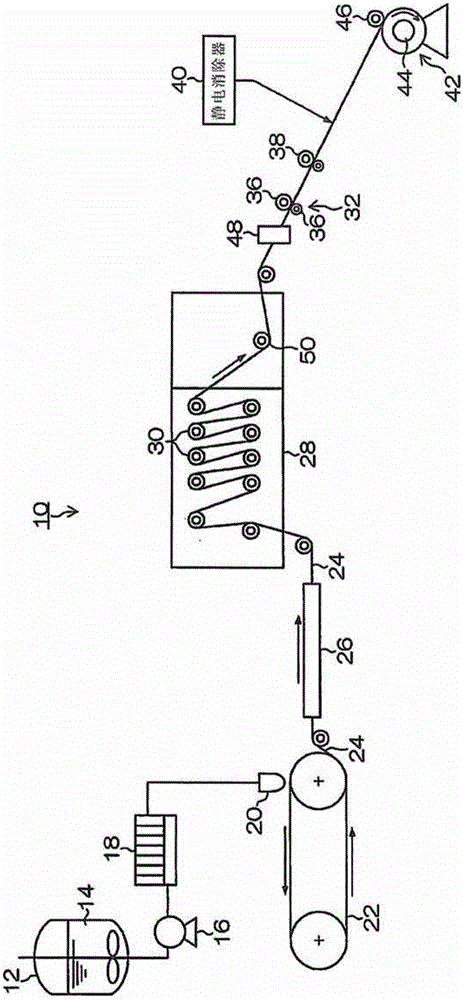

[0090] Cellulose triacetate was dissolved in a mixed solution of methylene chloride and methanol to form a dope, and the dope was cast on a stainless steel belt to form a thin film. In the dope, in addition to cellulose triacetate as the main raw material, plasticizers such as triphenyl phosphate and biphenyl diphenyl phosphate, ultraviolet (ultraviolet, UV) absorbers, and silicon dioxide are also mixed. Department of matting agent.

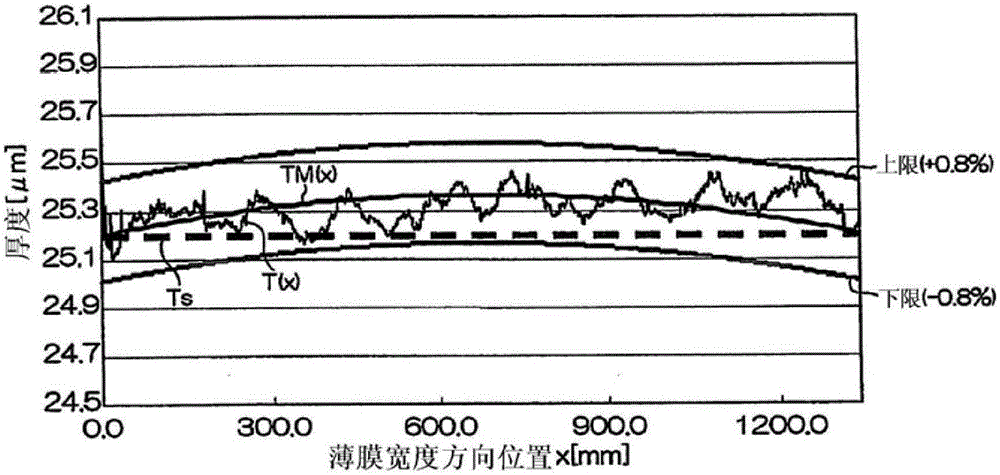

[0091] After the film cast on the stainless steel belt was heat-treated and sufficiently dried, knurling processing with a width of 10 mm was given, and the winding tension was set at 300 N to wind up for 3900 m. The film width was set to 1340 mm, and the thickness was set to 25 μm.

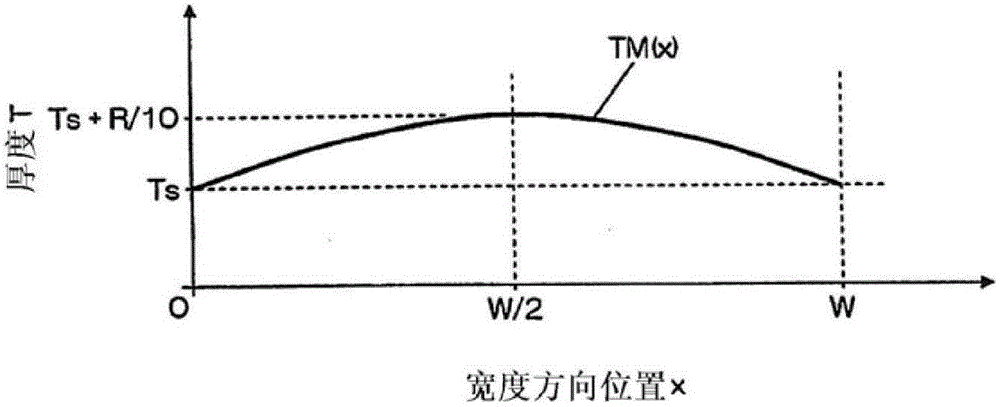

[0092] Here, an optical film roll having a winding length of 3900 m was produced for three standards. The first is an optical film roll made with the existing film thickness, the second is an optical film roll with T(x) in the range of 100±1.6% of TM(x), and the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com