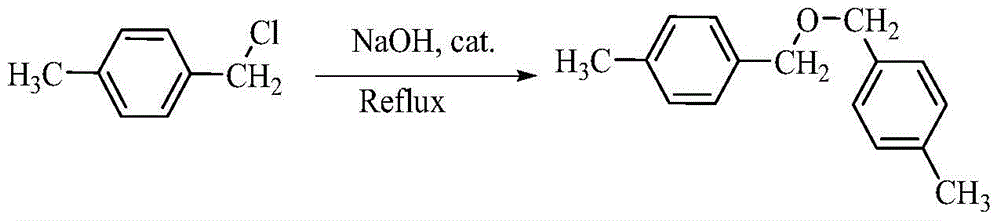

The preparation method of 4,4'-dimethyl dibenzyl ether

A technology of dimethyl dibenzyl ether and p-methyl benzyl chloride, which is applied in the field of preparation of 4,4'-dimethyl dibenzyl ether, can solve the problems of low efficiency and long reaction time, and achieve simplified reactions Process, short reaction time, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of preparation method of 4,4'-dimethyl dibenzyl ether, it comprises the following steps successively:

[0024] 1) In a 1000mL glass reaction bottle, first add 281g of p-methylbenzyl chloride (purity: 99.0%, 2.0mol), then add 480g (3.0mol) of NaOH solution with a mass percentage concentration of 25%, and add 5.6 g tetrabutylammonium bromide (purity is 99.0%), heated up to 110°C under stirring, and refluxed for 6 hours;

[0025] 2) The reaction material was cooled to room temperature under stirring, white crystals were precipitated, and the obtained white solid was dried in the air to obtain 246.5 g of crude product; the purity of 4,4'-dimethyldibenzyl ether in the crude product was 90.40% (GC) , the yield is 98.6%;

[0026] 3) Take 50.0 g of the crude product of 4,4'-dimethyldibenzyl ether and place it in a 500 ml four-neck flask, add 25 g of 95.0% (purity, GC) ethanol, heat to reflux, and stop heating after all the solids are dissolved , continue to stir and co...

Embodiment 2

[0029] A kind of preparation method of 4,4'-dimethyl dibenzyl ether, it comprises the following steps successively:

[0030] 1) In a 1000mL glass reaction bottle, first add 281g of p-methylbenzyl chloride (purity: 99.0%, 2.0mol), then add 480g (3.0mol) of NaOH solution with a mass percentage concentration of 25%, and add 5.2 g triethylamine heated to 110° C. under stirring, and refluxed for 6 hours;

[0031] 2) The reaction material was cooled to room temperature under stirring, white crystals were precipitated, and the obtained white solid was air-dried to obtain 215.2 g of crude product; the purity of 4,4'-dimethyldibenzyl ether was 96.39% (GC), The yield is 91.8%;

[0032] 3) Take 50.0 g of the crude product of 4,4'-dimethyldibenzyl ether and place it in a 500 ml four-neck flask, add 25 g of 95.0% (purity, GC) ethanol, heat to reflux, and stop heating after all the solids are dissolved , continue to stir and cool to room temperature, a white solid is precipitated, suction...

Embodiment 3

[0035] A kind of preparation method of 4,4'-dimethyl dibenzyl ether, it comprises the following steps successively:

[0036] 1) In a 500mL glass reaction bottle, first add 70.3g of p-methylbenzyl chloride (purity: 99.0%, 0.5mol), then add 150g (0.75mol) of NaOH solution with a mass percentage concentration of 20%, and add 1.1g of tetrabutylammonium bromide, heated to 108°C under stirring, and refluxed for 6 hours;

[0037] 2) The reaction material was cooled to room temperature under stirring, white crystals were precipitated, and the obtained white solid was air-dried to obtain 63 g of crude product; the purity of 4,4'-dimethyldibenzyl ether was 93.35% (GC), and the obtained The rate is 104%.

[0038] 3) Take 50.0 g of the crude product of 4,4'-dimethyldibenzyl ether and place it in a 500 ml four-neck flask, add 25 g of 95.0% (purity, GC) ethanol, heat to reflux, and stop heating after all the solids are dissolved , continue to stir and cool to room temperature, a white sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com