System and method for preparing ammonia by heterogeneous catalytic hydrolysis of SCR denitration urea

A heterogeneous catalysis and heterogeneous technology, applied in the system field of SCR denitration urea heterogeneous catalytic hydrolysis to produce ammonia, can solve the complex structure of the three-phase fluidized hydrolysis reaction device, the long response time of ammonia gas demand signal, Catalytic hydrolysis reaction rate is slow and other problems, to achieve the effect of improving system responsiveness, reducing system energy consumption and investment and operating costs, and fast chemical reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

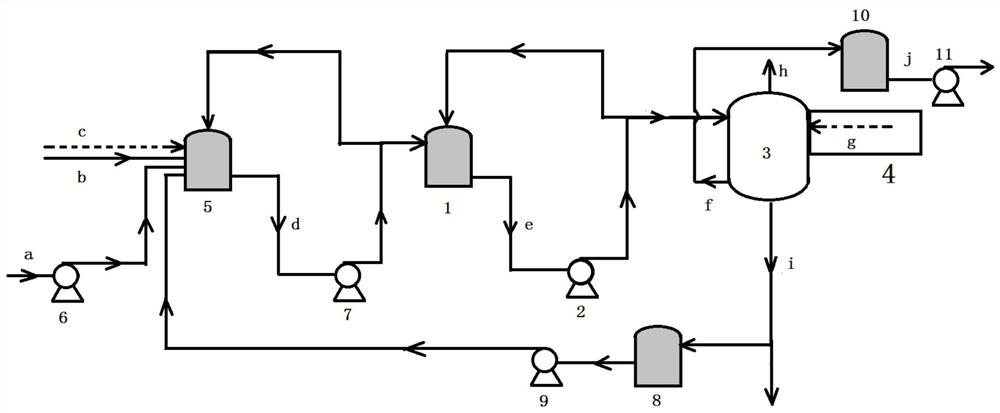

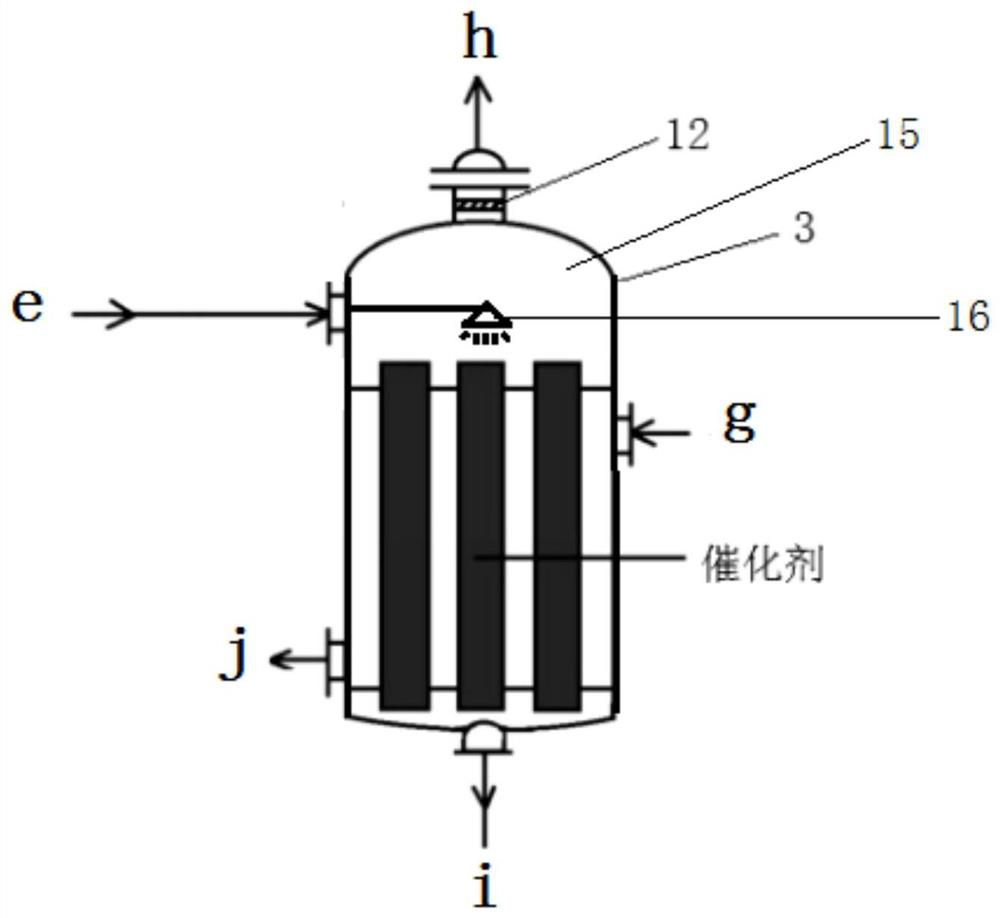

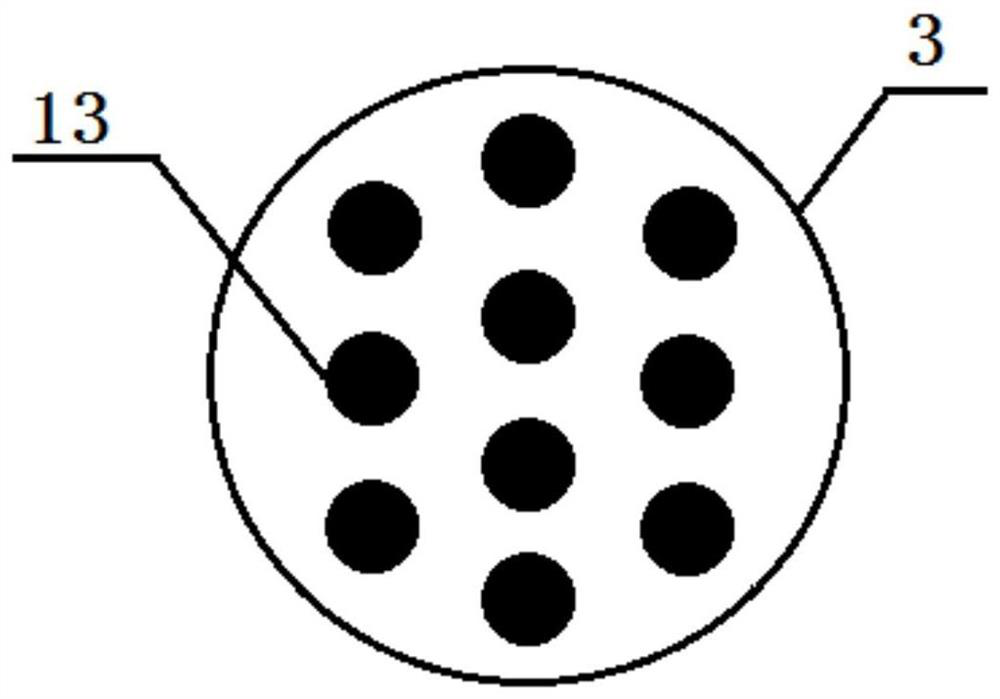

[0055] A system for producing ammonia by heterogeneous catalytic hydrolysis of SCR denitrification urea. like Figure 1-Figure 5 As shown, a system for SCR denitrification urea heterogeneous catalytic hydrolysis ammonia production system includes: urea configuration system, urea heterogeneous hydrolysis reaction system, raffinate discharge and recovery system and hydrophobic recovery system; the urea heterogeneous The hydrolysis reaction system comprises a urea solution storage tank 1, A urea solution delivery pump 2, a heterogeneous hydrolysis reactor 3 and a steam pipeline 4, and the heterogeneous hydrolysis reactor 3 adopts a tubular fixed-bed reactor; The urea solution storage tank 1 is connected to the heterogeneous hydrolysis reactor 3 through the A urea solution delivery pump 2 and the pipeline, and the steam pipeline 4 is connected to the heterogeneous hydrolysis reactor 3; the urea solution storage tank 1 is connected to the urea configuration system through the pipel...

Embodiment 2

[0056] Example 2: A system for producing ammonia by heterogeneous catalytic hydrolysis of SCR denitrification urea. like Figure 1-Figure 5 As shown, a system for SCR denitrification urea heterogeneous catalytic hydrolysis ammonia production system includes: urea configuration system, urea heterogeneous hydrolysis reaction system, raffinate discharge and recovery system and hydrophobic recovery system; the urea heterogeneous Hydrolysis reaction system comprises urea solution storage tank 1, A urea solution delivery pump 2, heterogeneous phase hydrolysis reactor 3 and steam pipe 4, and described heterogeneous phase hydrolysis reactor 3 adopts tubular fixed bed reactor; The urea solution storage tank 1 is connected to the heterogeneous hydrolysis reactor 3 through the A urea solution delivery pump 2 and the pipeline, and the steam pipeline 4 is connected to the heterogeneous hydrolysis reactor 3; the urea solution storage tank 1 is connected to the urea configuration system thro...

Embodiment 3

[0059] Example 3: A system for producing ammonia by heterogeneous catalytic hydrolysis of SCR denitrification urea. like Figure 1-Figure 5As shown, a system for SCR denitrification urea heterogeneous catalytic hydrolysis ammonia production system includes: urea configuration system, urea heterogeneous hydrolysis reaction system, raffinate discharge and recovery system and hydrophobic recovery system; the urea heterogeneous Hydrolysis reaction system comprises urea solution storage tank 1, A urea solution delivery pump 2, heterogeneous phase hydrolysis reactor 3 and steam pipe 4, and described heterogeneous phase hydrolysis reactor 3 adopts tubular fixed bed reactor; The urea solution storage tank 1 is connected to the heterogeneous hydrolysis reactor 3 through the A urea solution delivery pump 2 and the pipeline, and the steam pipeline 4 is connected to the heterogeneous hydrolysis reactor 3; the urea solution storage tank 1 and the urea configuration system pass through the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com