Photothermal conversion nanometer material as well as preparation method and application method thereof

A nanomaterial and photothermal conversion technology, applied in the field of nanomaterials and methods, can solve the problems of difficult size control, complex preparation process, and difficulty in avoiding the quenching effect of metal nanostructures on up-conversion luminescence, and achieves easy operation and repeatability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

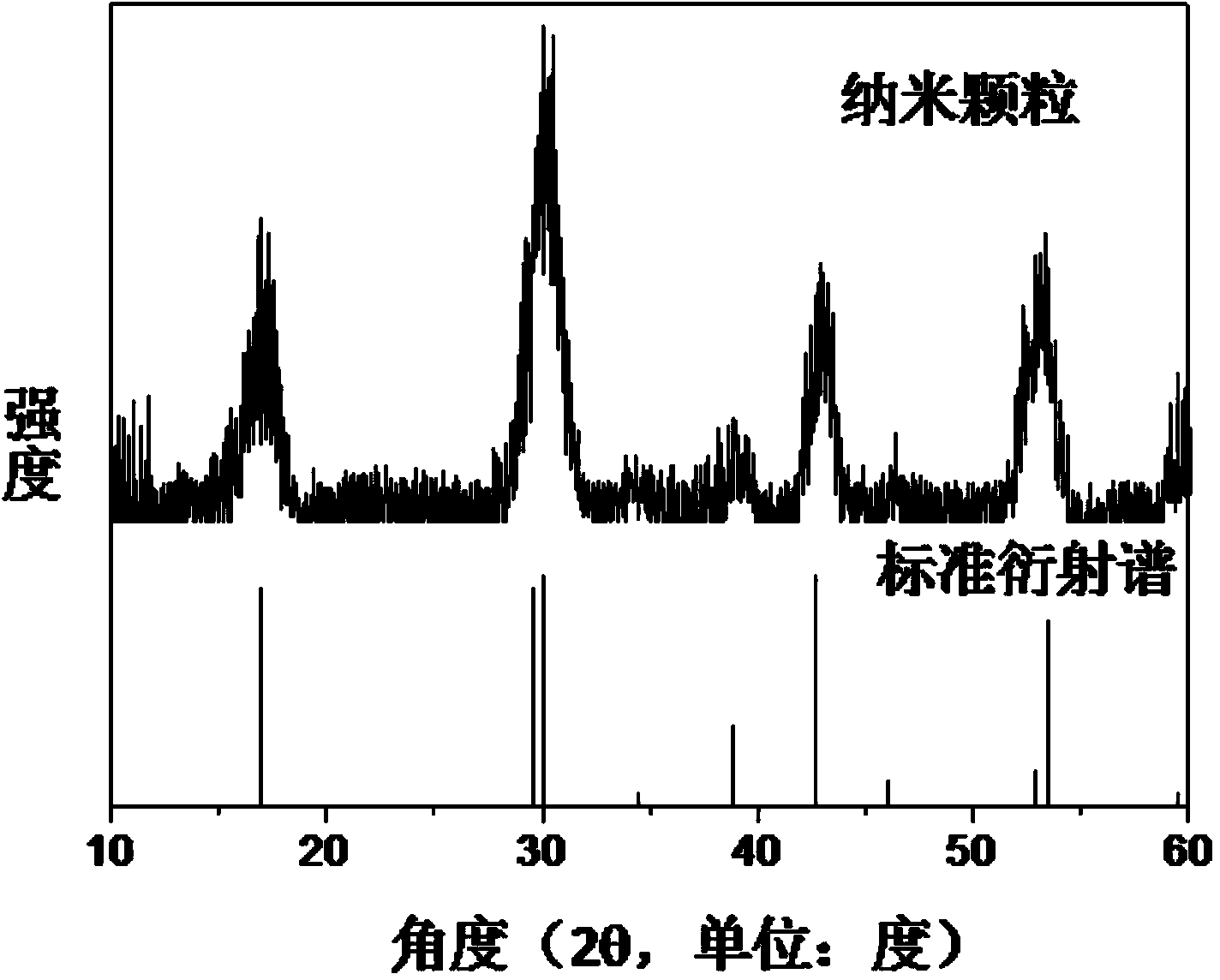

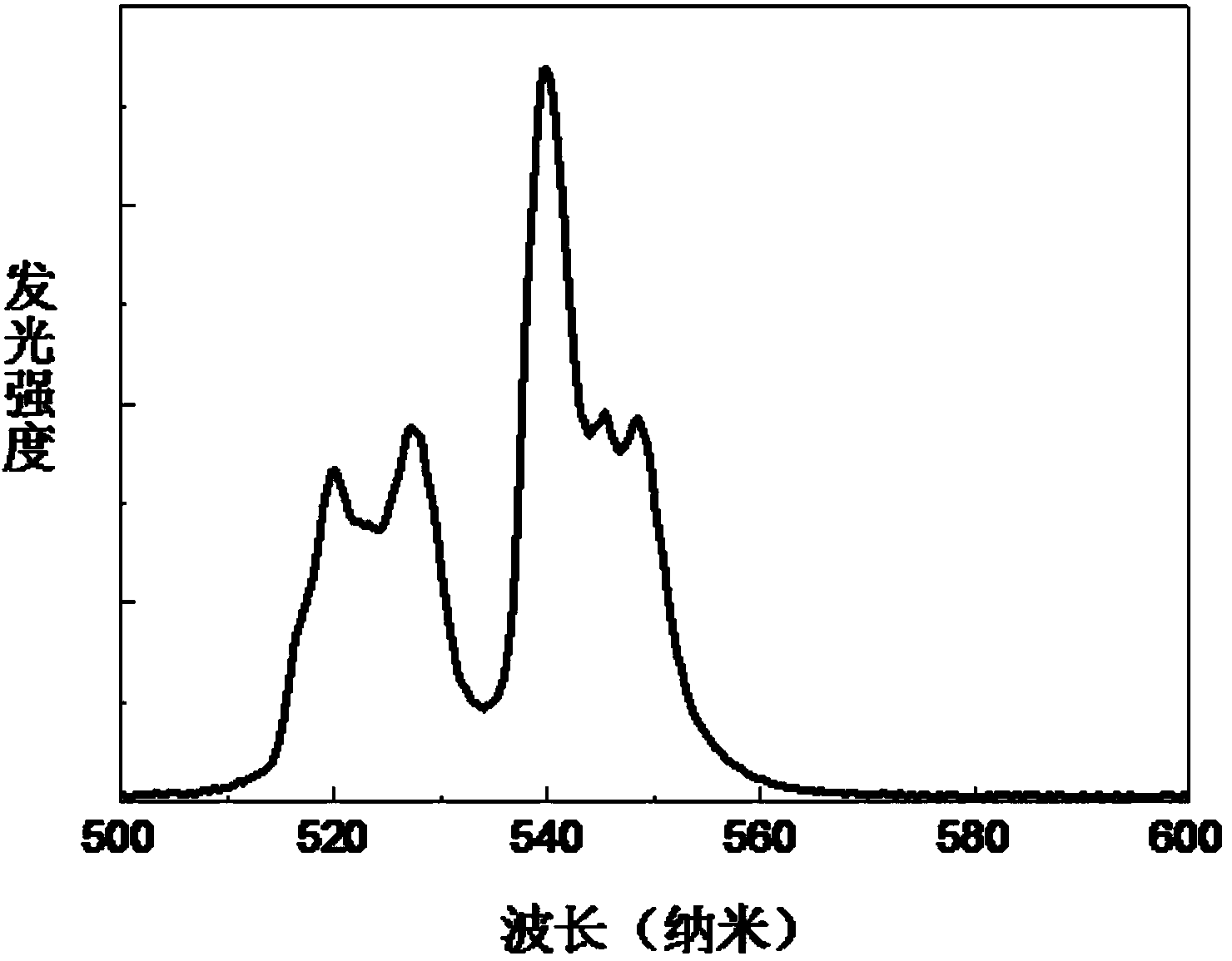

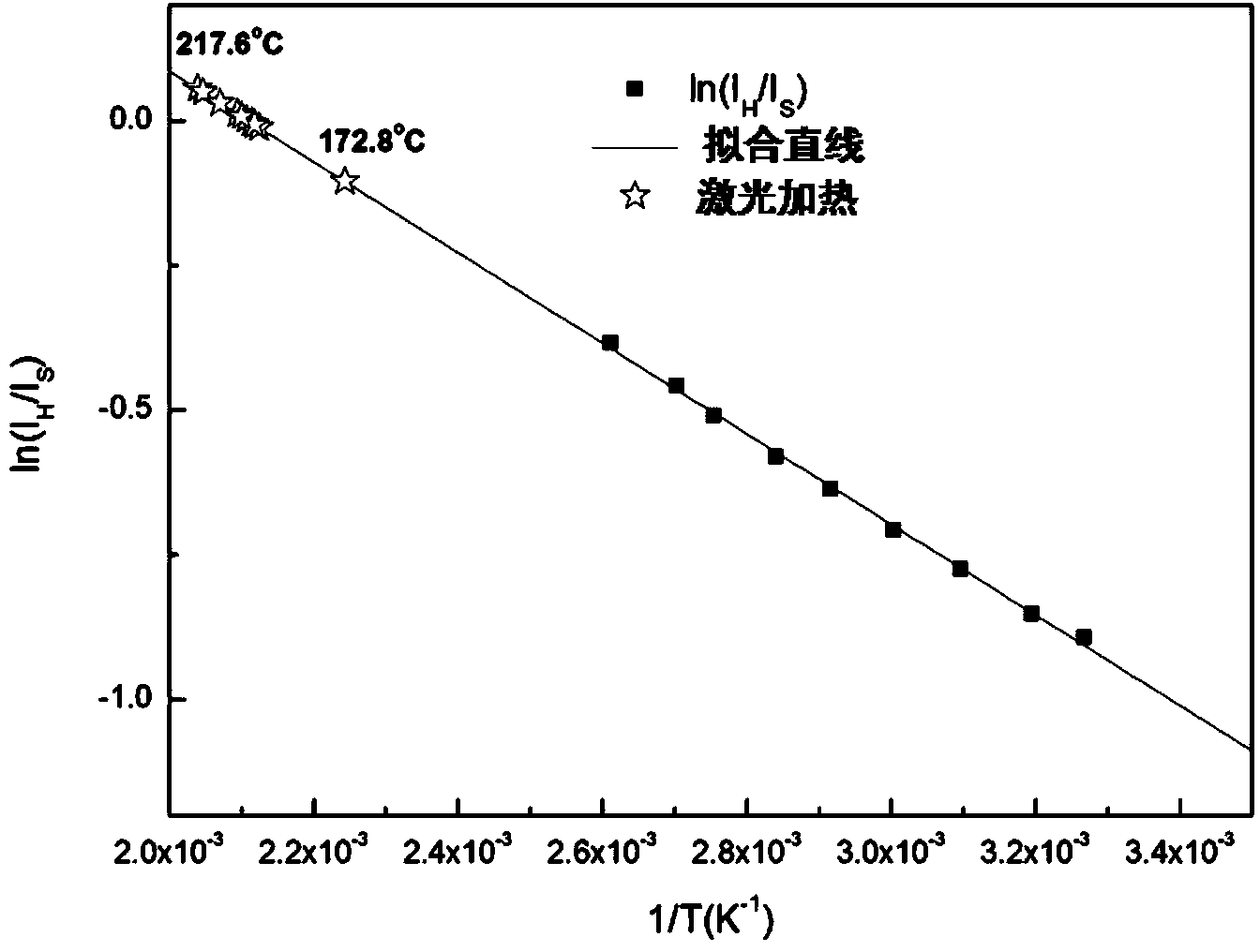

[0033] Weigh raw material Er(CH 3 COO) 3 0.02mmol, Yb(CH 3 COO) 3 0.2mmol, Gd(CH 3 COO) 3 0.78mmol, measure 15ml of 1-octadecene and 6ml of oleic acid as the reaction solvent. After mixing the raw materials and solvent, stir and heat to 110°C under Ar atmosphere, and keep it warm for 30min to form a clear and transparent rare earth ion precursor solution. Cool to 50°C under Ar atmosphere. Weigh 2.5mmol NaOH and 4mmol NH 4F was dissolved in 10ml of methanol, and then added to the above-mentioned rare earth ion precursor solution, and then the mixed solution was kept at 50°C for 30min under Ar atmosphere, and then the temperature was raised to 70°C to remove the methanol in the mixed solution, and then the temperature was rapidly raised to 305°C, and kept 90min. The final solution was cooled to 90° C., added with 20 ml of ethanol and centrifuged three times to obtain well-dispersed nanoparticles with a particle diameter of about 7.5 nm. Its microscopic morphology, crysta...

Embodiment 2

[0035] Weigh raw material Er(CH 3 COO) 3 0.02mmol, Yb(CH 3 COO) 3 0.2mmol, Y(CH 3 COO) 3 0.78mmol, take 15ml of 1-octadecene and 6ml of oleic acid as the reaction solvent. After mixing the raw materials and solvent, stir and heat to 160°C under Ar atmosphere, and keep it for 20min to form a clear and transparent rare earth ion precursor solution. Cool to 25°C under Ar atmosphere. Weigh 2.5mmol NaOH and 4mmol NH 4 F was dissolved in 10ml of methanol, and then added to the above-mentioned rare earth ion precursor solution, and then the mixed solution was kept at 50°C for 30min under Ar atmosphere, and then the temperature was raised to 100°C to remove the methanol in the mixed solution, and then the temperature was rapidly raised to 300°C, and kept 90min. The final solution was cooled to 90° C., added with 20 ml of ethanol and centrifuged three times to obtain well-dispersed nanoparticles with a particle diameter of about 26 nm.

Embodiment 3

[0037] Weigh raw material Er(CH 3 COO) 3 0.02mmol, Yb(CH 3 COO) 3 0.2mmol, Y(CH 3 COO) 3 0.78mmol, measure 15ml of 1-octadecene and 6ml of oleic acid as the reaction solvent. After mixing the raw materials and solvent, stir and heat to 100°C under Ar atmosphere, and keep it warm for 60min to form a clear and transparent rare earth ion precursor solution. Cool to 50°C under Ar atmosphere. Weigh 2.5mmol NaOH and 3mmol NH 4 F was dissolved in 10ml of methanol, and then added to the above-mentioned rare earth ion precursor solution, and then the mixed solution was kept at 50°C for 30min under Ar atmosphere, and then the temperature was raised to 70°C to remove the methanol in the mixed solution, and then the temperature was rapidly raised to 320°C, and kept 90min. The final solution was cooled to 90° C., added with 20 ml of ethanol and centrifuged three times to obtain well-dispersed nanoparticles with a particle diameter of about 40 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com