High-strength and high-plastic seawater corrosion-resistant alloy, its preparation method and application

A seawater-resistant and high-plastic technology, applied in the field of alloys, can solve problems such as poor high-temperature mechanical properties, and achieve the effects of low cost, simple preparation method and scientific formulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment discloses an Al-Co-Cr-Fe-Ni high-strength, high-plasticity seawater corrosion-resistant alloy, whose general formula is AlCoCrFeNi 1.9 .

[0027] The preparation method is as follows: the raw materials Al, Co, Mn, Cr, Fe and Ni are mixed according to the molar ratio, wherein Al, Co, Mn, Cr, Fe and Ni are all selected from industrial grade pure raw materials with a purity of more than 99 wt%. Then use the atmospheric medium frequency induction furnace for vacuum melting. When melting the alloy, the Al and Cr raw materials are placed at the bottom, the Fe and Ni raw materials are placed at the top, and the Co raw material is placed in the middle. The temperature is set at 1400 degrees Celsius, and the homogenization and heat preservation time of the alloy liquid after complete melting is 10 minutes. Obtained AlCoCrFeNi AlCoCrFeNi alloy with high strength, high plasticity and seawater corrosion resistance 1.9 .

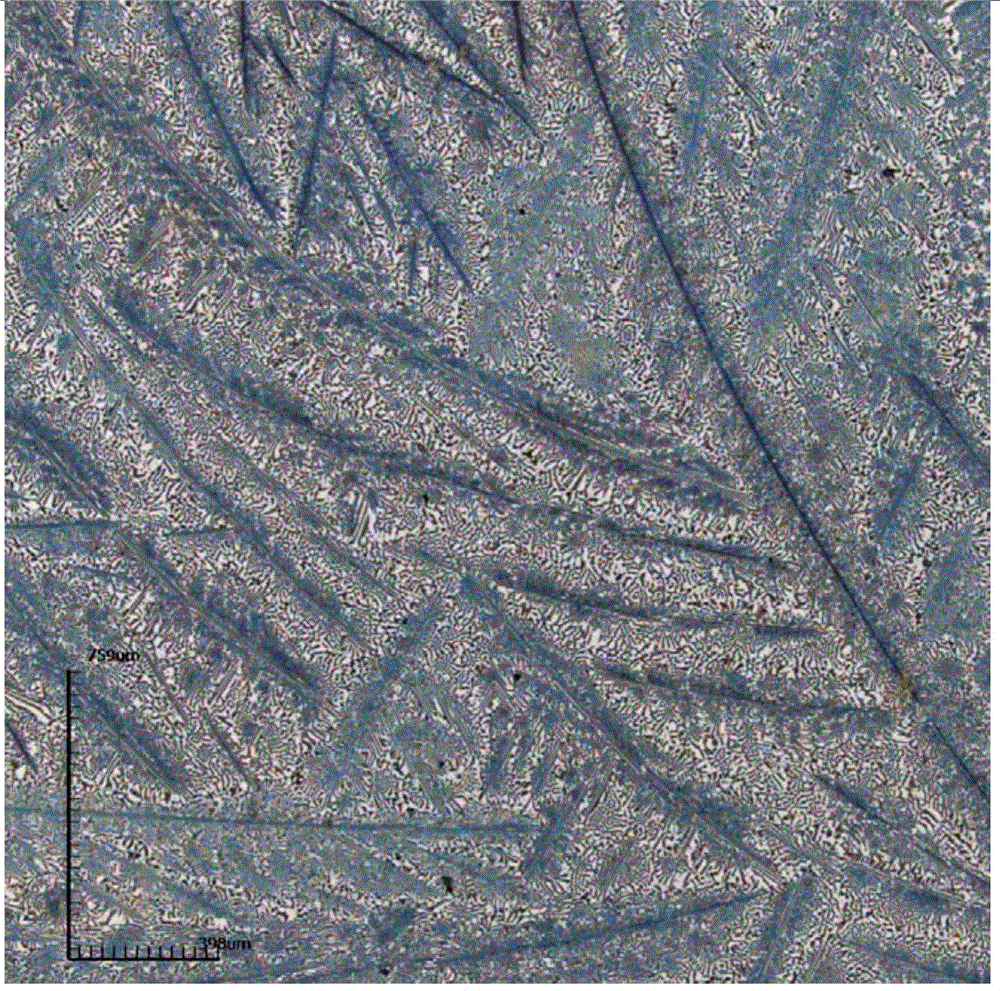

[0028] High-strength and high-plastic sea...

Embodiment 2

[0030] This embodiment discloses an Al-Co-Cr-Fe-Ni high-strength, high-plasticity seawater corrosion-resistant alloy, whose general formula is AlCoCrFeNi 2.1 .

[0031] Its preparation method is identical with embodiment 1.

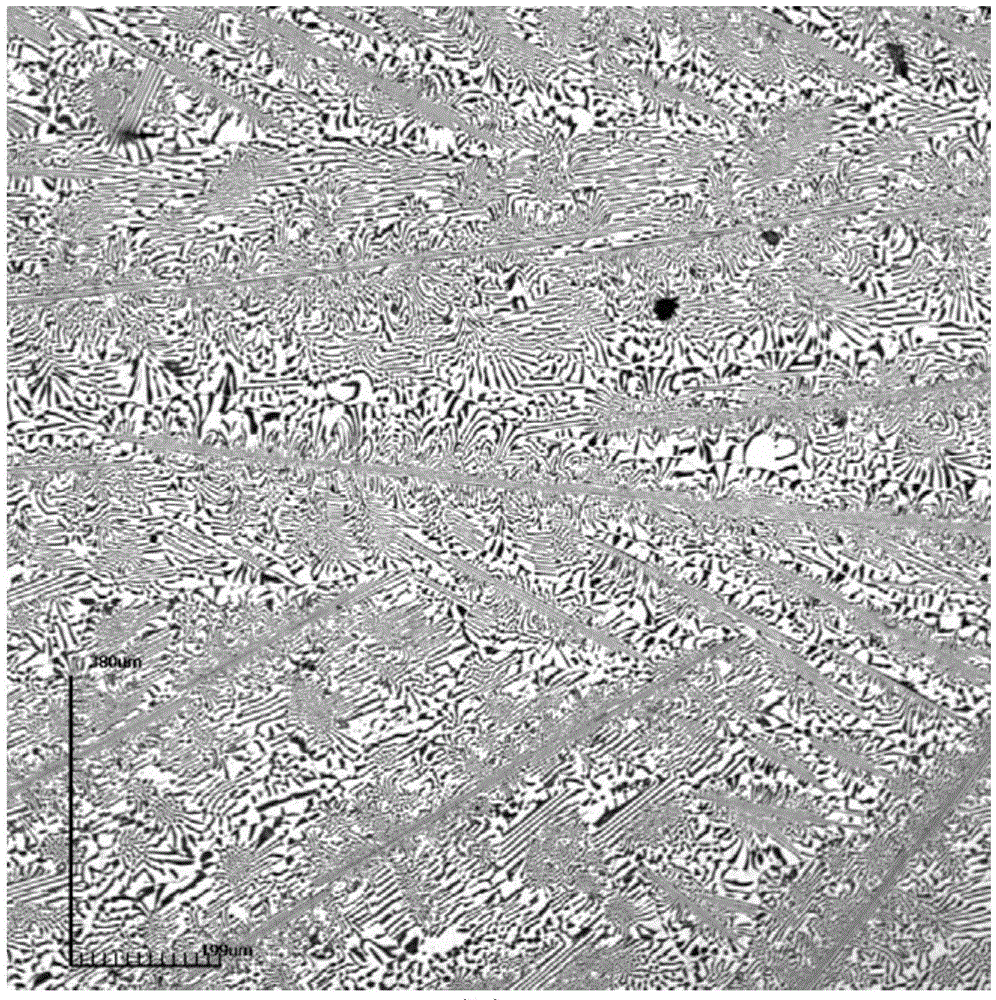

[0032] High-strength and high-plastic seawater corrosion-resistant alloy AlCoCrFeNi of the present invention 2.1 Laser confocal microscope microstructure pictures such as figure 2 It can be seen that almost all the structures in the figure are regular and uniform lamellar mixed structures composed of FeCoCr-rich phase and NiAl-rich phase.

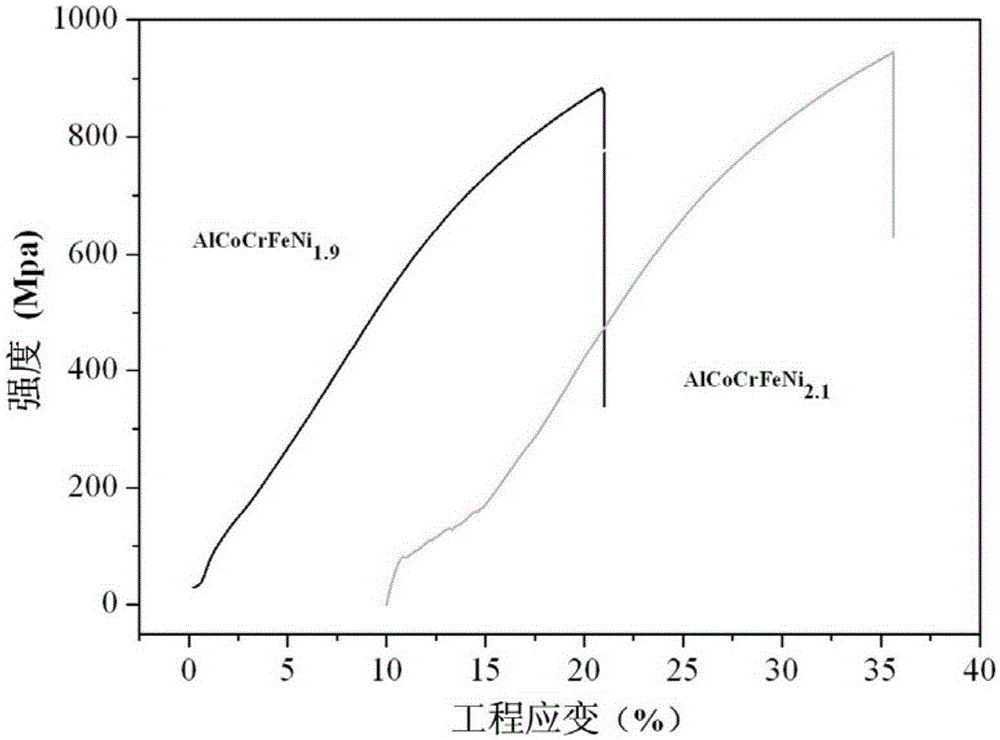

[0033] attached image 3 It is the engineering strain curve of the high-strength, high-plastic seawater corrosion-resistant alloy in Example 1 and Example 2 under normal temperature conditions; Figure 4 It is the engineering strain curve of the high-strength, high-plasticity seawater corrosion-resistant alloy in Example 1 and Example 2 under the condition of 600 degrees Celsius; Figure 5 It is the engineering s...

Embodiment 3

[0037] This embodiment discloses a high-strength, high-plasticity seawater corrosion-resistant alloy whose general formula is AlMnCrFeNi 2.0 . The preparation method of the high-strength, high-plastic seawater corrosion-resistant alloy in this embodiment is the same as that in Embodiment 1.

[0038] After testing this embodiment AlMnCrFeNi 2.0 It also has excellent high-temperature mechanical properties and corrosion resistance, and can be widely used in key metal parts requiring high strength, high plasticity, and high corrosion resistance in the marine field or in key metal parts in ultra-supercritical power stations.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com