Method for determining alcohol hydroxyl value

A sample and weighing technology, applied in the field of analysis, can solve the problems of incomplete reaction, poor acylation ability, large operating error, etc., achieve high accuracy and reproducibility, accurate measurement results, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

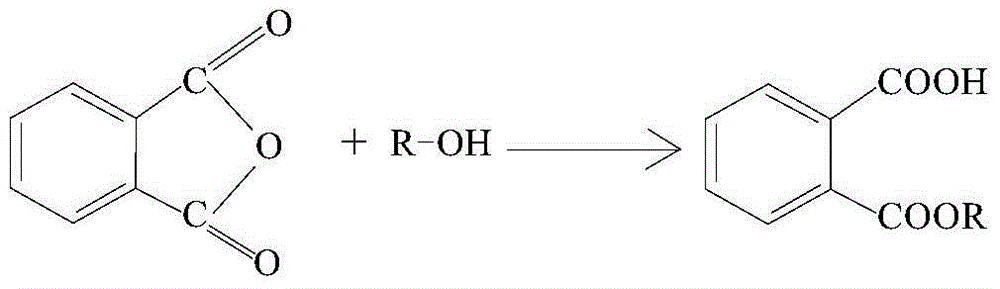

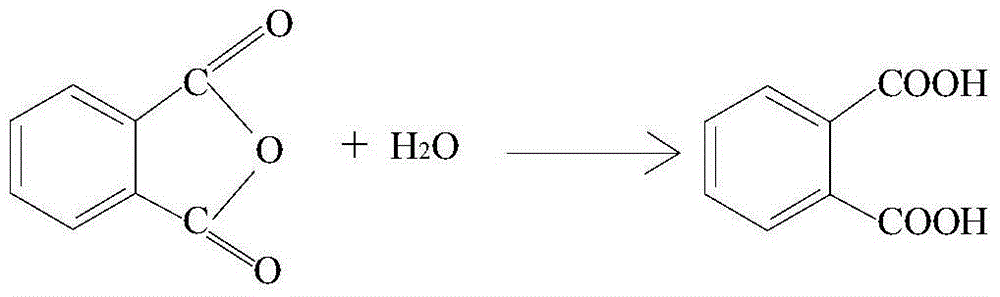

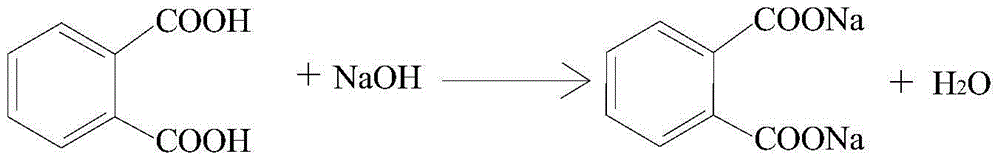

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1 measures the hydroxyl value of PEG1000

[0074] Weigh 3.4571g of the PEG1000 sample and place it in a 500ml conical flask (do not allow the sample to contact the neck of the bottle), add 0.35g of anhydrous sodium acetate; draw 2mL of acetic anhydride with a pipette and add it to the conical flask containing the sample, Use a constant temperature heating magnetic stirrer to keep the system temperature at 85±2°C and continue heating for 5 to 10 minutes, add 25mL of distilled water, continue heating to boiling, and keep shaking to make the solution clear and transparent; remove the round bottom flask, cool to room temperature, add 0.5 mL phenolphthalein indicator (3-5 drops), neutralized with 0.5061mol / L sodium hydroxide standard solution until reddish, then accurately add 30mL of 0.5061mol / L sodium hydroxide solution (in order to prevent bumping, add a few glasses Beads), heated to boil for 10min, cooled rapidly to room temperature, added 0.5mL phenolphthalei...

Embodiment 2

[0076] Embodiment 2 measures the hydroxyl value of PEG2000

[0077] Weigh 3.3684g of the PEG2000 sample and place it in a 500ml conical flask (do not allow the sample to contact the neck of the bottle), add 0.35g of anhydrous sodium acetate; draw 2mL of acetic anhydride with a pipette and add it to the conical flask containing the sample, Use a constant temperature heating magnetic stirrer to keep the system temperature at 85±2°C and continue heating for 5 to 10 minutes, add 25ml of distilled water, continue heating to boiling, and keep shaking to make the solution clear and transparent. Take off the Erlenmeyer flask, cool to room temperature, add 0.5ml phenolphthalein indicator (3-5 drops), neutralize with 0.5061mol / L sodium hydroxide standard solution to reddish, then accurately add 30ml of 0.5061mol / L hydroxide Sodium solution (a few glass beads can be added to prevent bumping), heat to boil for 10 minutes, rapidly cool to room temperature, add 0.5ml phenolphthalein indicat...

Embodiment 3

[0079] Embodiment 3 measures the hydroxyl value of GAP

[0080] Weigh 3.4631g of the GAP sample and place it in a 500ml Erlenmeyer flask (do not allow the sample to come into contact with the neck of the bottle), add 0.35g of anhydrous sodium acetate; draw 2mL of acetic anhydride with a pipette and add it to the Erlenmeyer flask containing the sample, Use a constant temperature heating magnetic stirrer to keep the system temperature at 85±2°C and continue heating for 5 to 10 minutes, add 25ml of distilled water, continue heating to boiling, and keep shaking to make the solution clear and transparent. Take off the Erlenmeyer flask, cool to room temperature, add 0.5ml phenolphthalein indicator (3-5 drops), neutralize with 0.5061mol / L sodium hydroxide standard solution to reddish, then accurately add 30ml of 0.5061mol / L hydroxide Sodium solution (a few glass beads can be added to prevent bumping), heat to boil for 10 minutes, rapidly cool to room temperature, add 0.5ml phenolphth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com