Optimization processing method for preparation of SERS substrate based on FIB direct-writing processing

A processing method and substrate technology, applied in digital control, gaseous chemical plating, electrical program control, etc., can solve problems affecting processing accuracy, difficult to process structural characteristics and stability maintenance, and difficult to obtain microstructure, etc., to achieve guaranteed Stability, guarantee of high flexibility, effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

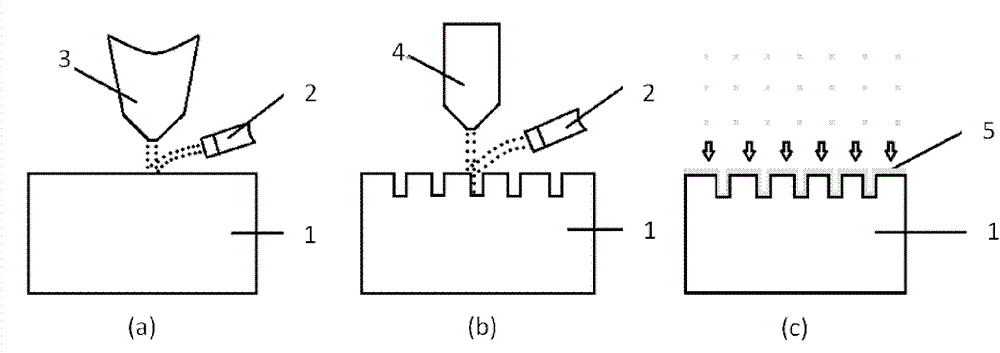

[0025] see figure 1 Firstly, the monocrystalline silicon sample substrate 1 is placed in the sample chamber of the dual-beam system, and the morphology of the sample is observed by the electron beam imaging system 3 . Using the focused ion beam 2 to perform ion etching processing on the single crystal silicon sample substrate 1 according to the target pattern, the focused ion beam etching parameters are adjusted according to the pattern and size, and on the basis of considering the broadening effect of the ion beam and combining the coating process parameters, A certain processing width is reserved, the accelerating voltage is controlled between 10kV-50kV, and the ion beam operating current is between 1pA-20nA, and then the electron beam imaging system 3 is used to observe whether the processed surface 4 meets the requirements of the experimental design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com