Nanofibrous three-dimensional nickel hydroxide/carbon nanotube composite material and its preparation method and application

A carbon nanotube and nanofiber technology, applied in the field of nickel hydroxide/carbon nanotube composite materials, can solve the problems of cumbersome steps, uncontrollability, complicated operation, etc., and achieve the effect of simple operation steps and good capacitance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] B. Preparation of flaky nickel hydroxide: mix 18mL distilled water with 18mL containing 0.03mol / L NiCl 2 Mix well with 0.045mol / L urea aqueous solution, then transfer to a 50mL reactor, then place the nickel foam pretreated in step a vertically in the reactor, and react under hydrothermal conditions at 150°C for 6 hours; after the reaction is completed, cool naturally , take out the nickel foam, wash it with distilled water, and dry it at 60°C for 12 hours to obtain flaky nickel hydroxide on the nickel foam substrate.

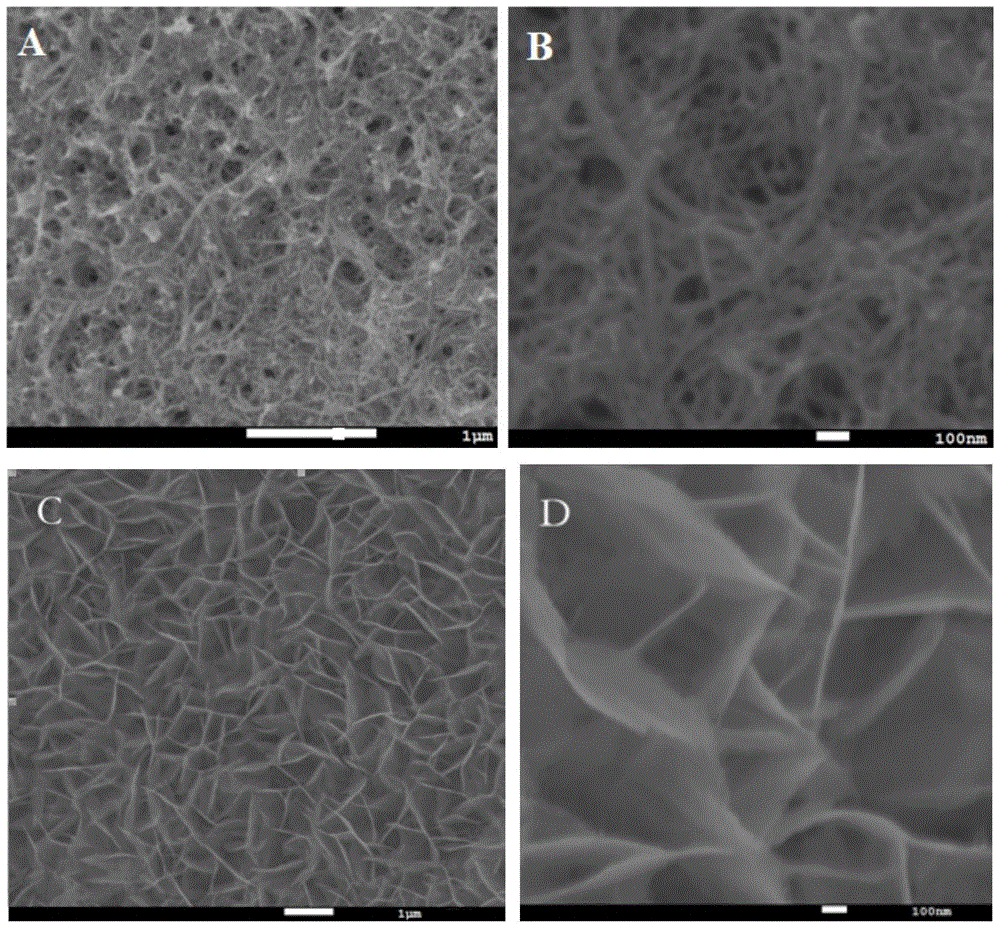

[0033] The scanning electron micrograph and partial enlargement figure of gained flaky nickel hydroxide are as follows respectively figure 1 C. figure 1 D shows. It can be seen that if carbon nanotubes are not added to the hydrothermal reaction system, sheet-like nickel hydroxide will be obtained on the nickel foam substrate under the same reaction temperature and reaction time conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com