Flow improver for resin coated sand

A fluidity and improver technology, applied in casting and molding equipment, molds, cores, etc., can solve the problems of reducing molding operability, reducing mold strength, cracks, etc., to suppress blocking phenomenon, improve bulk density, Improved operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

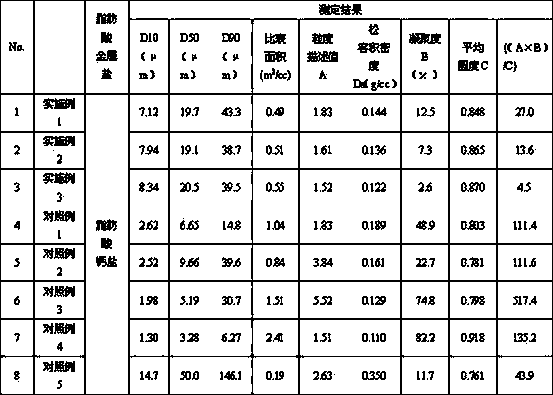

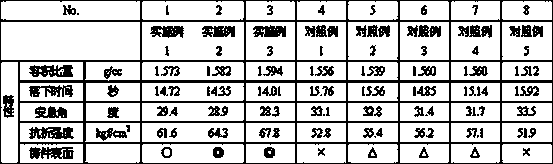

Embodiment 1)

[0089] In a 3L separable flask, add 250 g of mixed fatty acids (containing 2.1% by mass of myristic acid, 30.3% by mass of palmitic acid, 66.5% by mass of stearic acid, 0.8% by mass of arachidic acid and 0.3% by mass of dill acid.), 0.75 g of polyethylene glycol? polypropylene glycol? block ether (manufactured by NOF Co., Ltd., trade name: Pronon#104), and 2500 g of water, and the temperature was raised to 90°C. Next, 77.2 g of 48 mass % sodium hydroxide aqueous solution was added, and it stirred at the same temperature (90 degreeC) for 1 hour, and obtained the fatty acid alkali compound salt aqueous solution. Thereafter, 151.2 g of a 35% by mass calcium chloride aqueous solution was dropped into the fatty acid alkali compound salt aqueous solution over 10 minutes while keeping 90° C. constant. After completion of the dropping, the mixture was aged at 90° C. while stirring for 10 minutes. 1500 g of water was added to the obtained mixed fatty acid calcium salt aqueous solution...

Embodiment 2)

[0091]In a 3L separable flask, add 250 g of mixed fatty acids (containing 2.1% by mass of myristic acid, 30.3% by mass of palmitic acid, 66.5% by mass of stearic acid, 0.8% by mass of arachidic acid and 0.3% by mass of dill acid.), and 2500g of water, until the temperature rises to 80°C. Next, 77.2 g of 48 mass % sodium hydroxide aqueous solution was added, and it stirred at the same temperature (80 degreeC) for 1 hour, and obtained the fatty acid alkali compound salt aqueous solution. Thereafter, 151.2 g of a 35% by mass calcium chloride aqueous solution was dropped into the fatty acid alkali compound salt aqueous solution over 30 minutes while keeping 80° C. constant. After completion of the dropping, the mixture was aged while stirring at 80° C. for 30 minutes. 1500 g of water was added to the obtained mixed fatty acid calcium salt aqueous solution slurry, and the mixture was cooled to 65° C. or lower. Then, it was filtered with a suction filter, washed twice with 1000 g ...

Embodiment 3)

[0093] In a 3L separable flask, add 250 g of mixed fatty acids (containing 1.6% by mass of myristic acid, 24.0% by mass of palmitic acid, 73.4% by mass of stearic acid, 0.7% by mass of arachidic acid and 0.3% by mass of dill acid.), 0.75 g of polyethylene glycol? polypropylene glycol? block ether (manufactured by NOF Co., Ltd., trade name: Pronon#104), and 2500 g of water, and the temperature was raised to 70°C. Next, 76.5 g of 48 mass % sodium hydroxide aqueous solution was added, and it stirred at the same temperature (70 degreeC) for 1 hour, and obtained the fatty acid alkali compound salt aqueous solution. Thereafter, 150.1 g of a 35% by mass calcium chloride aqueous solution was dropped into the fatty acid alkali compound salt aqueous solution over 1 hour while keeping 70° C. constant. Immediately after the completion of the dropping, 1500 g of water was added to the obtained fatty acid alkali compound salt aqueous solution slurry, and the mixture was cooled to 65° C. or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com