Liquid fermentation medium for culturing edible mushroom liquid microbial strains and liquid microbial strain preparation method

A liquid strain and liquid fermentation technology, applied in the field of bioengineering, can solve the problems of low strain vigor, high pollution rate, production chaos, etc., and achieve the effects of reducing pollution rate, reducing labor costs, and saving seed production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

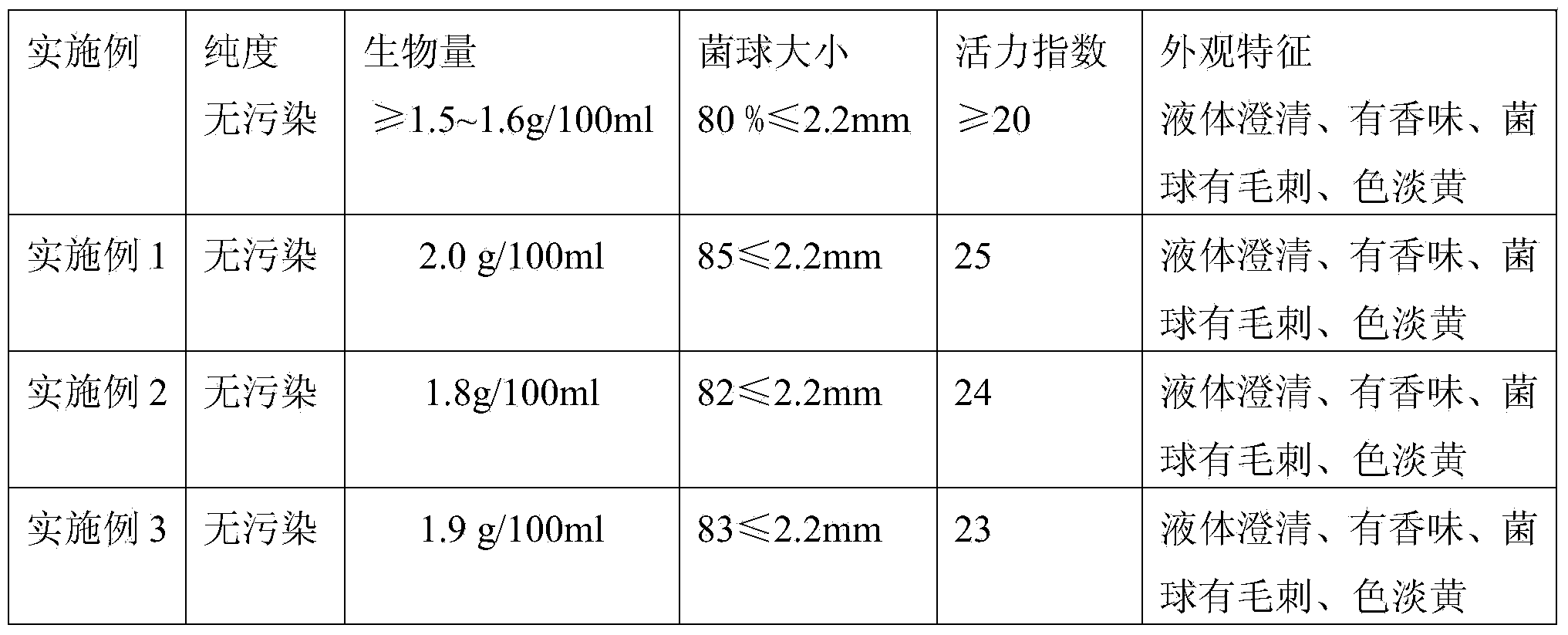

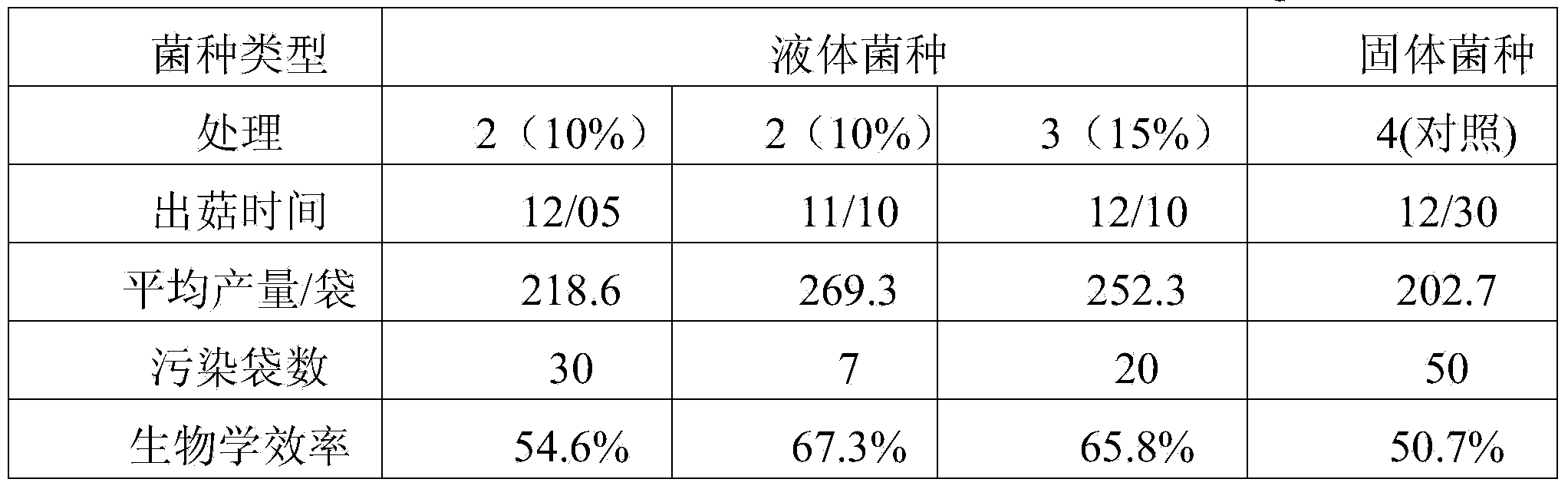

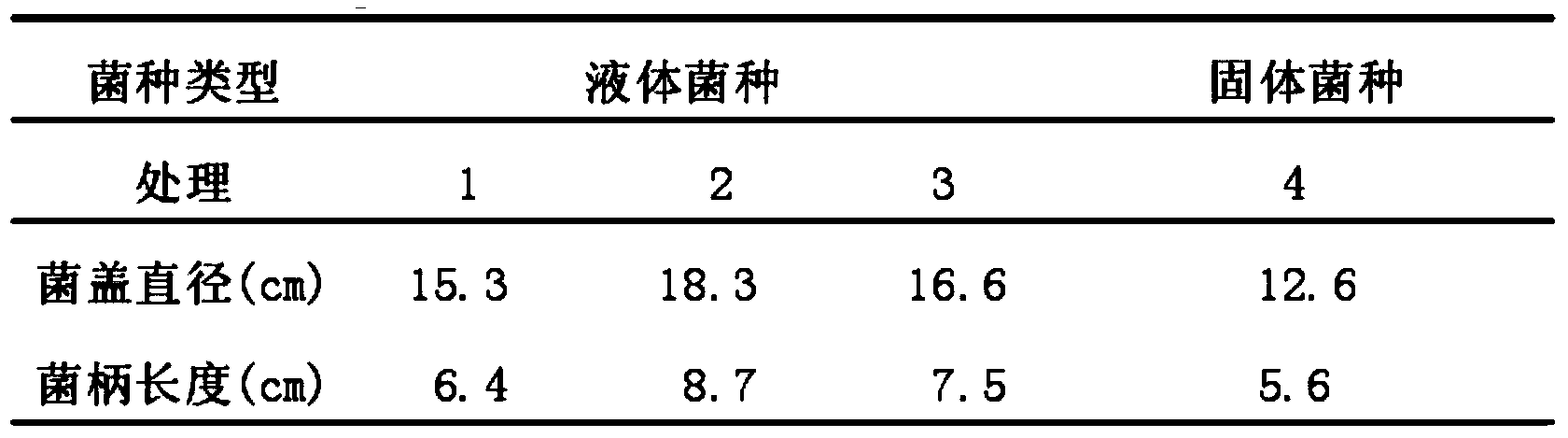

Examples

preparation example Construction

[0031] A method for preparing edible fungus liquid strains, comprising the following steps:

[0032] 1) Activation of slant strains: put the slant strains on PDA medium, and cultivate them at a constant temperature of 25°C for 7 days, and use them as primary strains;

[0033] 2) Cultivation of first-level liquid strains: put the seed liquid culture medium into a 300ml Erlenmeyer flask, the filling capacity of each bottle is 70-90ml, sterilize the seed liquid culture medium and inoculate the obtained in step 1 under a sterile environment The first-class strains were cultured in a shaker for 7 days;

[0034] 3) liquid fermentation: put the fermented liquid medium according to claim 1 into a fermenter, inoculate the liquid strain of step 2 gained in a sterile environment after the liquid medium is sterilized, and the inoculation amount is calculated as 8-12% of the culture medium, cultured with stirring for 3 days to make mycelium.

[0035] Production of liquid strains and its ...

Embodiment 1

[0039] A preparation method of Bailing mushroom liquid spawn, comprising the following steps:

[0040] 1) Activation of slant strains: put the slant strains on PDA medium, and cultivate them at a constant temperature of 25°C for 7 days, and use them as primary strains;

[0041] 2) Cultivation of the first-level liquid strain: put the seed liquid culture medium into a 300ml Erlenmeyer flask, the filling capacity of each bottle is 80ml, sterilize the seed liquid culture medium and inoculate the first-level obtained in step 1 under a sterile environment The strain, the inoculum amount is 8-12% of the culture medium by weight percentage, and it is placed in a shaker for 7 days; the seed liquid culture medium is: 3% corn flour, 2% wheat bran, 2% glucose, protein Chen 0.5%, MgSO 4 ·7H 2 O0.1%, KH 2 PO 4 0.1%, VB 1 10mg / L, soybean oil 0.03%. The initial pH value is 5.5, and the rotation speed of the shaker is 210r / min.

[0042] 3) liquid fermentation: put the liquid fermentati...

Embodiment 2

[0045] A preparation method of Bailing mushroom liquid spawn, comprising the following steps:

[0046] 1) Activation of slant strains: put the slant strains on PDA medium, and cultivate them at a constant temperature of 25°C for 7 days, and use them as primary strains;

[0047] 2) Cultivation of the first-level liquid strain: put the seed liquid culture medium into a 300ml Erlenmeyer flask, the capacity of each bottle is 70ml, sterilize the seed liquid culture medium and inoculate the first-level obtained in step 1 under a sterile environment Bacteria, the inoculation amount is 12% of the culture medium by weight percentage, and it is placed in a shaker for 7 days; the seed liquid culture medium is: 3% corn flour, 2% wheat bran, 2% glucose, and 0.5% egg white. %, MgSO 4 ·7H 2 O0.1%, KH 2 PO 4 0.1%, VB 1 10mg / L, soybean oil 0.03%. The initial pH value is 6.0, and the rotation speed of the shaker is 200r / min.

[0048] 3) liquid fermentation: put the liquid fermentation me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com