Denitrification device and generator set with economizer recirculation system

A recirculation system and economizer technology, applied in the field of denitrification, can solve the problems of increasing investment, system resistance, and rising power consumption in the plant, and achieve the effects of ensuring safe and stable operation, increasing flue gas temperature, and avoiding boiling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

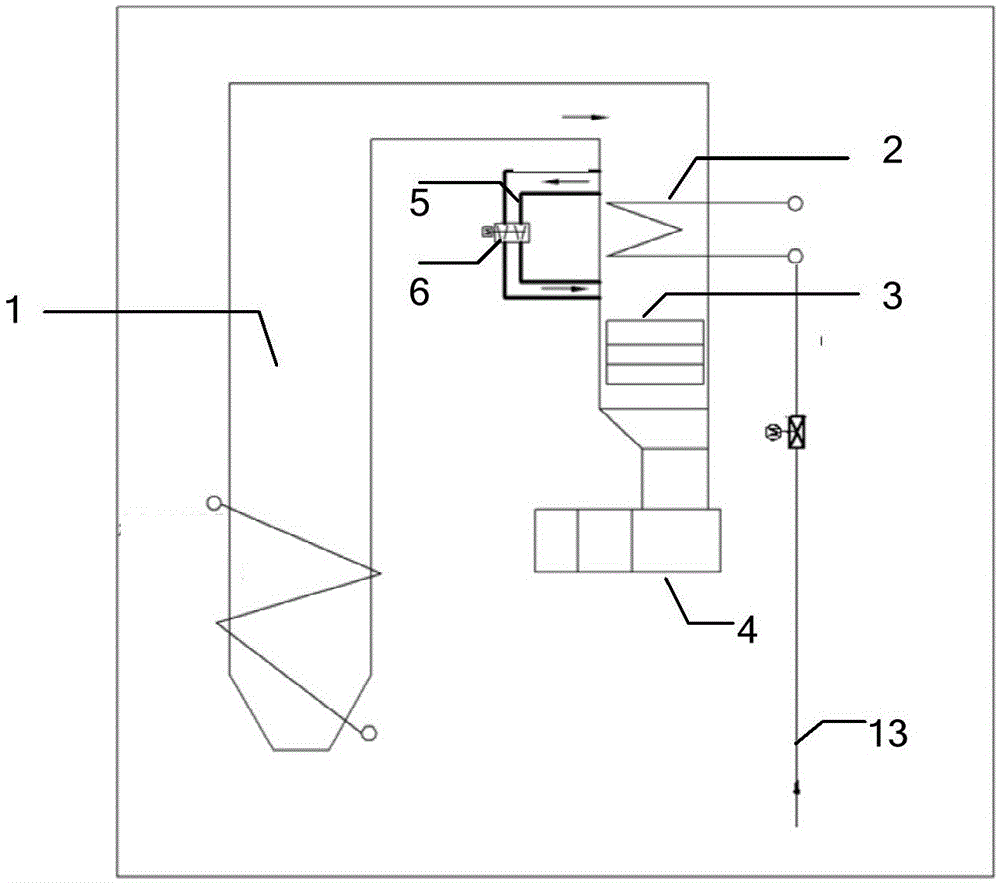

Embodiment 1

[0068] Example 1: Economizer recirculation scheme is adopted, and the parameters are as follows:

[0069] Economizer inlet water temperature: 260°C;

[0070] Economizer outlet water temperature: 286°C;

[0071] Water supply flow rate of main water supply pipeline: 222.2kg / s;

[0072] Water flow in economizer: 378kg / s;

[0073] Economizer inlet flue gas temperature: 416°C;

[0074] Economizer outlet flue gas temperature: 312°C.

[0075] Among them, the temperature of the water flow introduced into the economizer from the steam turbine through the main water supply pipe on the water side of the economizer is 242°C, and the flow rate is 222.2kg / s. After this part of the water flow is mixed with the water flow introduced from the recirculation system, the economizer The inlet water temperature is 260°C as mentioned above, and the flow rate is 378kg / s. After the flue gas absorbs heat through the water side of the economizer, the temperature of the flue gas changes from 416°C t...

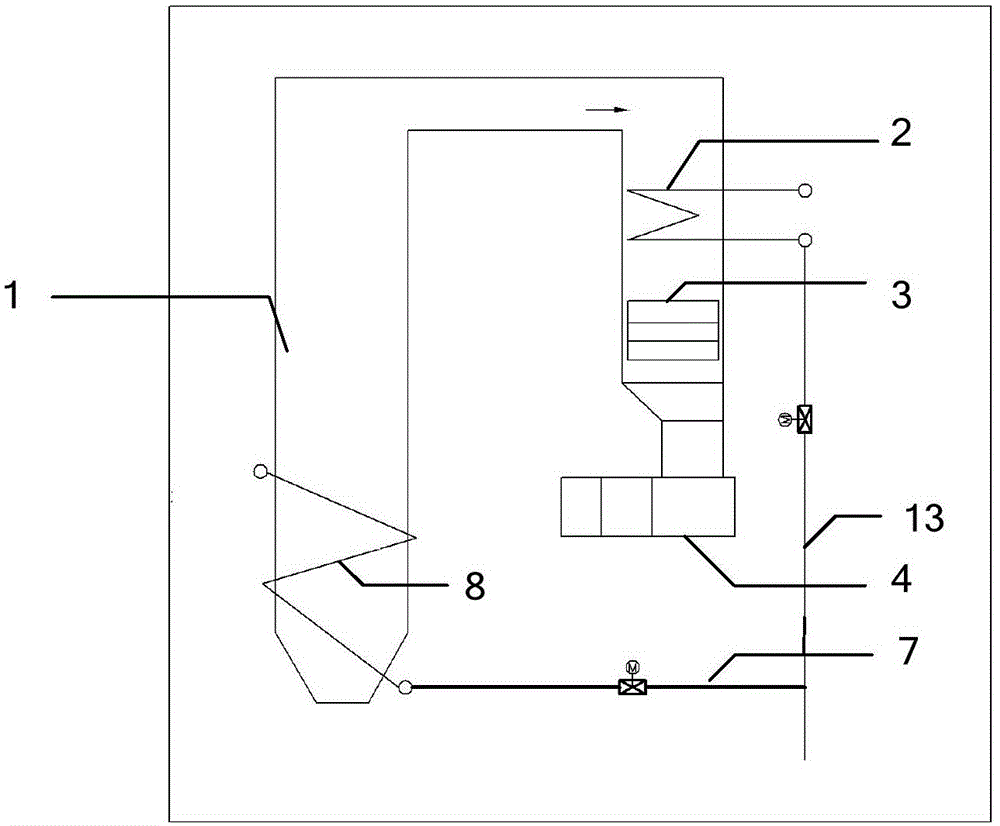

Embodiment 2

[0079] Example 2: Economizer recirculation combined with water side bypass scheme is adopted, and the parameters are as follows:

[0080] Economizer inlet water temperature: 259°C;

[0081] Economizer outlet water temperature: 299.5°C;

[0082] Water supply flow rate of main water supply pipeline: 222.2kg / s;

[0083] Water flow in economizer: 222.2kg / s;

[0084] Economizer inlet flue gas temperature: 416°C;

[0085] Flue gas temperature at the outlet of the economizer: 321°C.

[0086] It can be seen from the above calculation that the flow rate of the recirculation system is about 30% (the ratio of the flow rate introduced by the recirculation system to the flow rate introduced by the main water supply pipe), and at the same time, the feedwater is bypassed to the inlet header of the water wall by about 30%, which can save the economizer The outlet flue gas temperature increases to about 321°C. It can well meet the requirements of ammonia injection temperature.

[0087] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com