A silicon tetrachloride purification process and system

A technology of silicon tetrachloride and process, applied in the direction of silicon halide compound, halosilane, etc., can solve the problems of poor purification effect and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

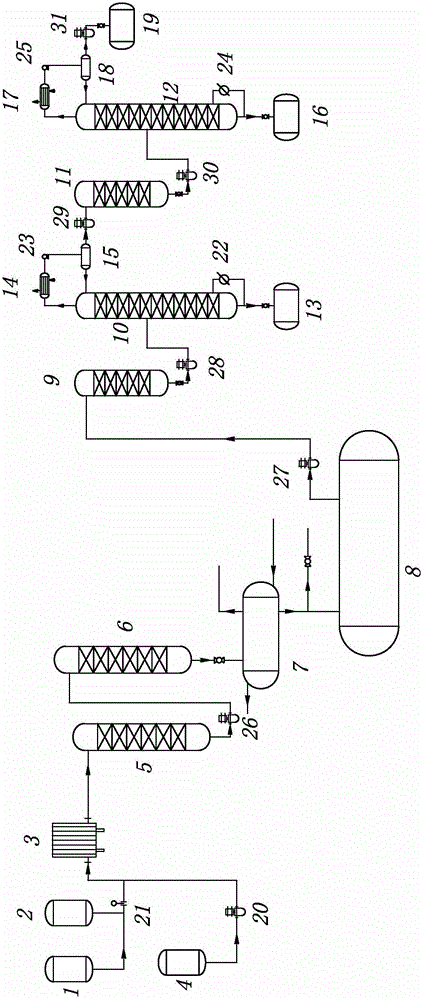

Method used

Image

Examples

Embodiment 1

[0038] A fixed bed reactor is adopted, the reaction temperature is controlled at 300°C, 350°C, 400°C, 450°C, 500°C, the gas residence time is 30s, the particle size of activated alumina is 3-5mm, and the average specific surface area is 340m 2 / g, the particle size of active silica gel is 75~150μm, and the average specific surface area is 400m 2 / g, the reflux ratio of the first rectifying tower is 10: 1, the reflux ratio of the second rectifying tower is 20: 1, the tower top temperature is controlled at 56~58 ℃, and the tower bottom temperature is controlled at 70~72 ℃.

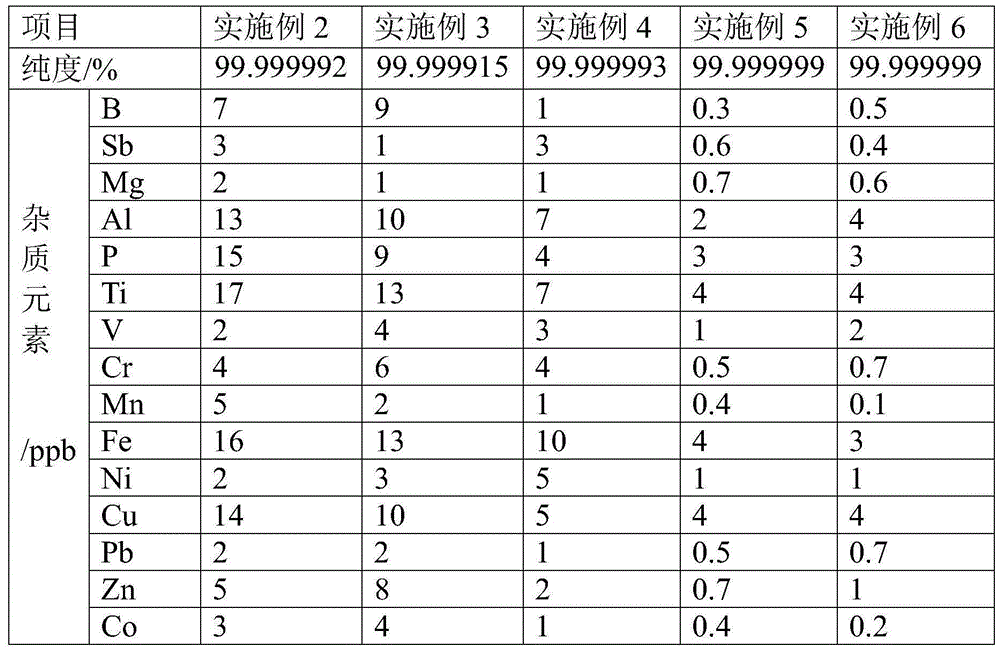

Embodiment 2

[0040] Adopt two-stage fixed-bed reactor, the temperature of the first section fixed-bed reactor is 300 ℃, the residence time 10s, the temperature of the second section fixed-bed reactor is 400 ℃, the residence time 20s, all the other parameters are the same as embodiment 1.

Embodiment 3

[0042] Two-stage fixed-bed reactors were adopted, the temperature of the first fixed-bed reactor was 350° C., and the residence time was 15 seconds. The temperature of the second-stage fixed-bed reactor was 450° C., and the residence time was 25 seconds.

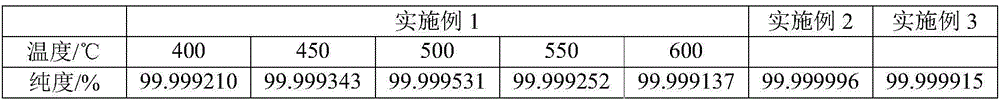

[0043] Table 1 Embodiment 1~3 silicon tetrachloride purity compares

[0044]

[0045] It can be seen from the above table that the purification efficiency of the two-stage fixed-bed reactor is significantly higher than that of the one-stage fixed-bed reactor, which may be because the residence time in the one-stage fixed-bed reactor is too long, resulting in local temperature changes and reduced impurity conversion efficiency.

[0046] In the one-stage reactor, the reaction temperature of 500°C has the best impurity removal effect, indicating that the impurity and chlorine react most fully at this temperature.

[0047] In Example 3, the reaction temperature is reduced and the gas residence time is prolonged, but the impur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com