Thermosensitive hydrogel and preparation method and application thereof

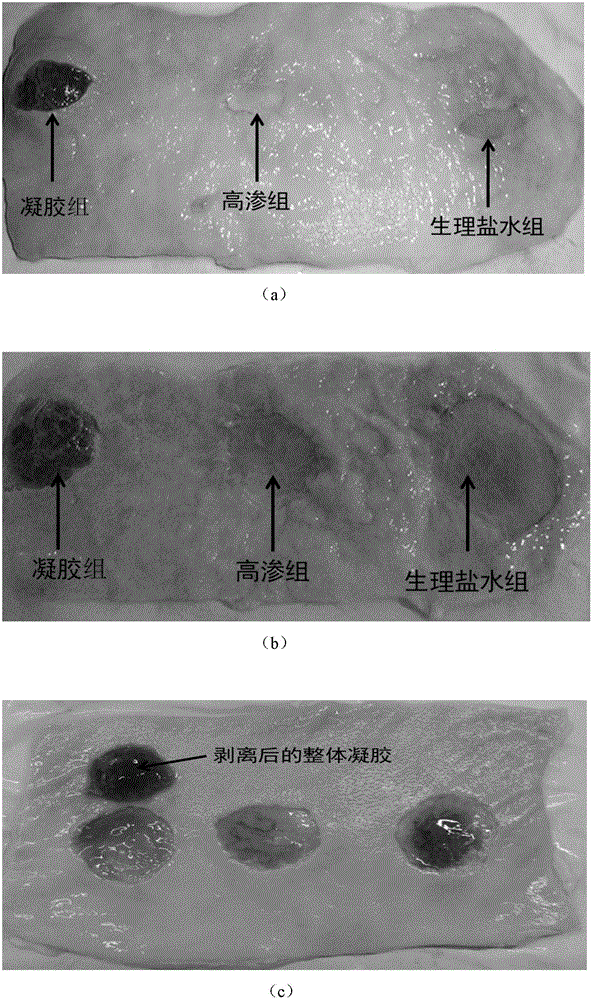

A temperature-sensitive hydrogel and lactide technology, applied in the field of medicine, can solve the problems of melanin diffusion, unclear labeling, and inconspicuous uplift effects, and achieve the effects of preventing diffusion, increasing accuracy, and reducing the risk of bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

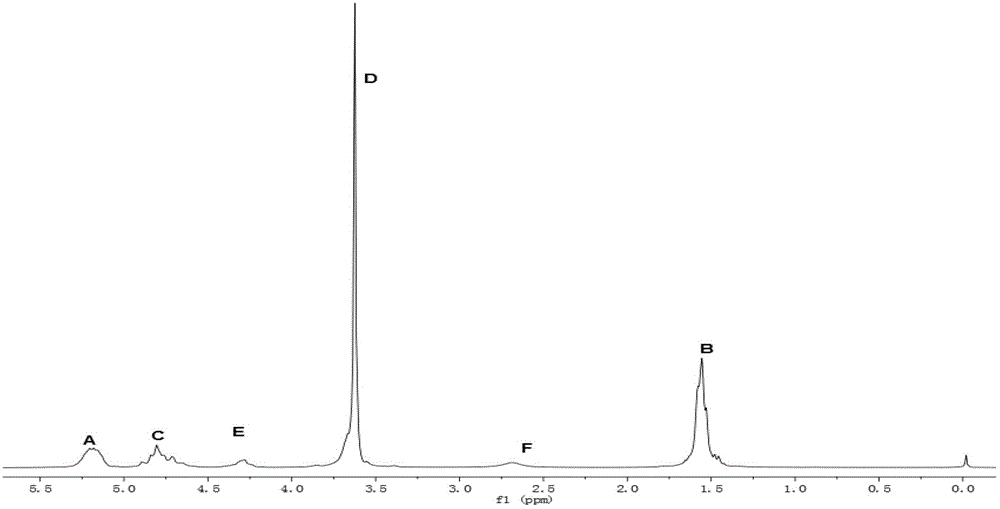

[0030] The preparation method of PLGA-PEG-PLGA triblock copolymer of the present invention comprises the following steps:

[0031] (1) After mixing PEG1000 and PEG1500 in a certain mass ratio, reflux under vacuum at a suitable temperature for 2 to 4 hours to remove the water in PEG1000 and PEG1500;

[0032] (2) Add lactide and glycolide, and heat it to 80-100°C for 5-20 minutes at an external temperature under vacuum conditions until the solid dissolves. The mass ratio of the added lactide to glycolide is 2-4: 1. The mass ratio of the sum of lactide and glycolide to the total amount of PEG is 1-2:1;

[0033] (3) After cooling to room temperature, add the catalyst, use a reflux condensing device to react at an external temperature of 120-160°C for 6-12 hours, stop heating and vacuumize for 20-40 minutes, and cool to room temperature to obtain the product PLGA-PEG-PLGA triembedded segment copolymers.

[0034] Preferably, after step (3), the following step (4) is also included:...

Embodiment 1

[0042] This embodiment prepares PLGA-PEG-PLGA triblock copolymer, comprises steps as follows:

[0043] (1) Add polyethylene glycol 1000 (PEG1000) and polyethylene glycol 1500 (PEG1500) into the three-necked bottle at a mass ratio of 1:1, and at a speed of 200r / min, the oil pump controls the vacuum at -0.1 MPa, external temperature 145°C, internal temperature 130°C, vacuum cold water reflux for 2 hours, remove a small amount of water in PEG1000 and PEG1500;

[0044] (2) Then cool to room temperature with high-purity nitrogen, add lactide (LA) and glycolide (GA), so that the ratio of LA / GA is 2:1, and the ratio of (LA+GA) / PEG is 1:1 , heat the external temperature to 100°C for 5 minutes under vacuum conditions until the solid dissolves;

[0045] (3) Cool to room temperature with nitrogen gas, add the catalyst stannous octoate, install a reflux condensing device, and react at an external temperature of 120°C for 6 hours, the reaction solution is light yellow and clear, stop heat...

Embodiment 2

[0049] This embodiment prepares PLGA-PEG-PLGA triblock copolymer, comprises steps as follows:

[0050] (1) Add polyethylene glycol 1000 (PEG1000) and polyethylene glycol 1500 (PEG1500) into the three-necked bottle at a mass ratio of 1:1, and at a speed of 200r / min, the oil pump controls the vacuum at -0.1 MPa, external temperature 145°C, internal temperature 130°C, vacuum cold water reflux for 3 hours, remove a small amount of water in PEG1000 and PEG1500;

[0051] (2) Then fill with high-purity nitrogen and cool to room temperature, add lactide (LA) and glycolide (GA), so that the ratio of LA / GA is 2.5:1, and the ratio of (LA+GA) / PEG is 2:1 , heat the external temperature to 90°C for 10 minutes under vacuum conditions until the solid dissolves;

[0052] (3) Cool to room temperature with nitrogen gas, add the catalyst stannous octoate, install a reflux condensing device, react at an external temperature of 142°C for 8 hours, the reaction solution is light yellow and clear, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com