Antimicrobial anticorrosive paint and preparation method thereof

An anti-bacterial and anti-corrosion coating technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of unsatisfactory anti-corrosion and anti-bacterial effects, coatings that do not have anti-bacterial and anti-corrosion effects, and do not pay attention to anti-bacterial and anti-corrosion effects of coatings, etc., to achieve excellent anti-bacterial and anti-corrosion properties. Excellent adhesion, the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

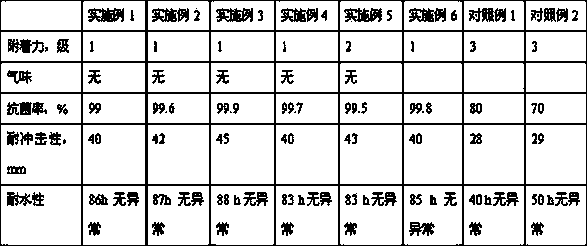

Examples

Embodiment 1

[0016] Antibacterial and anticorrosion coatings, including the following raw materials in parts by mass: 66 kg of acrylic resin, 16 kg of castor oil, 10 kg of vinyl acetate, 4 kg of dimethyl carbonate, 15 kg of nano-silica powder, 2 kg of polyacrylamide, 3- Aminopropyltriethoxysilane 1 kg, N-ethyl-p-toluenesulfonamide 1 kg, zinc oxide 5 kg, bamboo charcoal powder 2 kg, water 90 kg, ethanol 20 kg, ethyl acetate 10 kg.

[0017] The preparation method of the present embodiment comprises the following steps:

[0018] The first step: According to the mass ratio, mix 66 kg of acrylic resin, 16 kg of castor oil, 10 kg of vinyl acetate, 4 kg of dimethyl carbonate, 15 kg of nano-silica powder, 2 kg of polyacrylamide, 3-aminopropyl 1 kg of triethoxysilane was mixed and dispersed evenly, stirred at 40°C for 30 minutes, allowed to stand and cooled to obtain mixture A;

[0019] Step 2: mix and stir the mixture A obtained in step 1 with 1 kg of N-ethyl-p-toluenesulfonamide, 5 kg of zinc ox...

Embodiment 2

[0021] Antibacterial and anti-corrosion coatings, including the following raw materials in parts by mass: 70 kg of acrylic resin, 23 kg of castor oil, 13 kg of vinyl acetate, 6 kg of dimethyl carbonate, 18 kg of nano-silica powder, 7 kg of polyacrylamide, 3- Aminopropyltriethoxysilane 6 kg, N-ethyl-p-toluenesulfonamide 4 kg, zinc oxide 10 kg, bamboo charcoal powder 6 kg, water 100 kg, ethanol 30 kg, ethyl acetate 14 kg.

[0022] The preparation method of the present embodiment comprises the following steps:

[0023] The first step: According to the mass ratio, mix 70 kg of acrylic resin, 23 kg of castor oil, 13 kg of vinyl acetate, 6 kg of dimethyl carbonate, 18 kg of nano-silica powder, 7 kg of polyacrylamide, 3-aminopropyl 6 kg of triethoxysilane was mixed and dispersed evenly, stirred at 55°C for 30 minutes, allowed to stand and cooled to obtain mixture A;

[0024] Step 2: Mix and stir the mixture A obtained in step 1 with 4 kg of N-ethyl-p-toluenesulfonamide, 10 kg of zin...

Embodiment 3

[0026] Antibacterial and anti-corrosion coatings, including the following raw materials in parts by mass: 68 kg of acrylic resin, 20 kg of castor oil, 11 kg of vinyl acetate, 5 kg of dimethyl carbonate, 17 kg of nano-silica powder, 4 kg of polyacrylamide, 3 - 5 kg of aminopropyltriethoxysilane, 3 kg of N-ethyl-p-toluenesulfonamide, 8 kg of zinc oxide, 5 kg of bamboo charcoal powder, 95 kg of water, 25 kg of ethanol, and 13 kg of ethyl acetate.

[0027] The preparation method of the present embodiment comprises the following steps:

[0028] The first step: According to the mass ratio, mix 68 kg of acrylic resin, 20 kg of castor oil, 11 kg of vinyl acetate, 5 kg of dimethyl carbonate, 17 kg of nano-silica powder, 4 kg of polyacrylamide, 3-aminopropyl 5 kg of triethoxysilane was mixed and dispersed evenly, stirred at 50°C for 30 minutes, allowed to stand and cooled to obtain mixture A;

[0029] The second step: mix and stir the mixture A obtained in step 1 with 3 kg of N-ethyl p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com