Drive unit of insulated gate power control device

A power control and driving device technology, applied in electrical components, pulse technology, electronic switches, etc., can solve the problem of not meeting the requirements of fast driving insulated gate voltage control devices, inability to quickly switch high-current devices, and low driving current in driving circuits, etc. problem, to achieve the effect of high power utilization efficiency, easy promotion and low working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

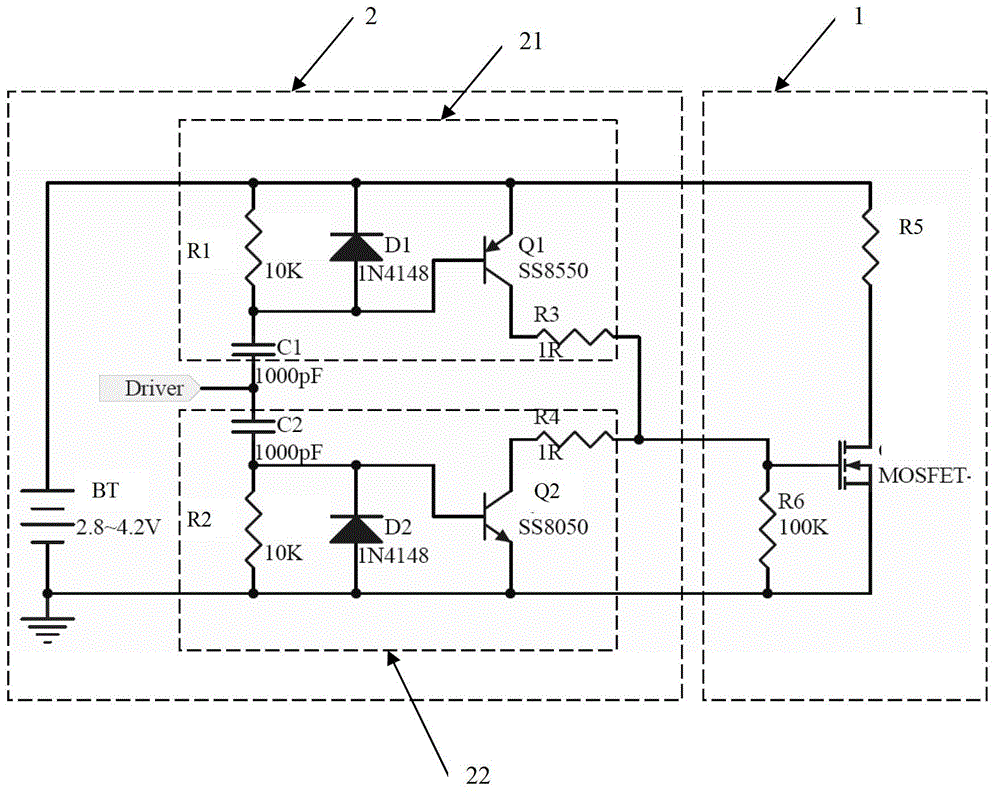

[0028] Such as figure 1 As shown, the drive device of the insulated gate power control device of the present invention includes a drive circuit 2 connected to the insulated gate power control device 1; the insulated gate power control device 1 used in this embodiment includes a MOSFET, resistors R5 and R6 , wherein the resistor R5 is the output load driven by the MOSFET, and R6 is the electrostatic discharge resistor. Of course, the isolated power control device 1 is not limited to this embodiment, for example figure 1 The composition of MOSEFT and resistors R5 and R6, wherein MOSEFT can be IGBT or other insulated gate power control devices; the drive circuit 2 includes a drive power supply BT, a high-side drive circuit 21 and a low-side drive circuit 22, the high-side The drive circuit 21 and the low-variation drive circuit 22 have a symmetrical structure up and down, and the high-side drive circuit 21 includes a first triode Q1, a first capacitor C1, a first diode D1, a firs...

Embodiment 2

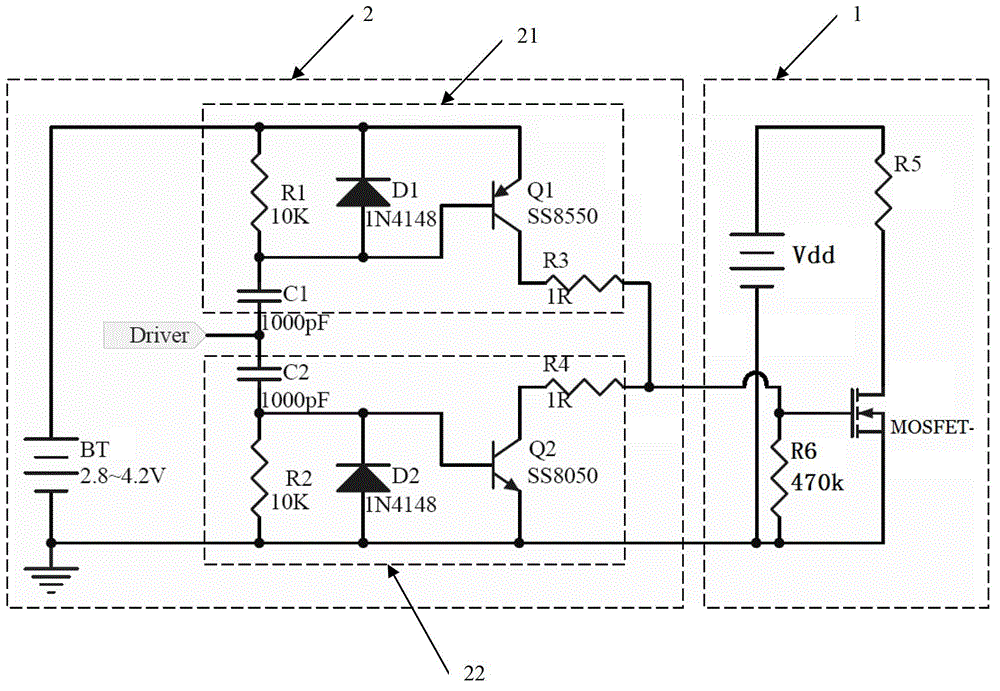

[0037] Such as figure 2 As shown, the difference between the embodiment and the embodiment 1 is only that the MOSFET in the insulated gate control device 1 has an independent working power supply Vdd, the purpose is that the MOSFET is not subject to any limitation of the driving power supply BT, so that the entire circuit The adaptability is wider.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com