Integrated high-efficiency autotrophic denitrification reactor

An autotrophic denitrification, integrated technology, applied in the field of biological denitrification of sewage, can solve the problems of difficulty in maintaining the stability of short-range nitrification process, reducing the activity of anammox bacteria, capital construction investment and large area, etc. Maintain high efficiency and stability, good granularity and high nitrogen removal load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

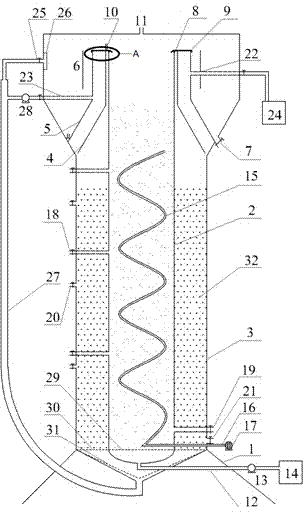

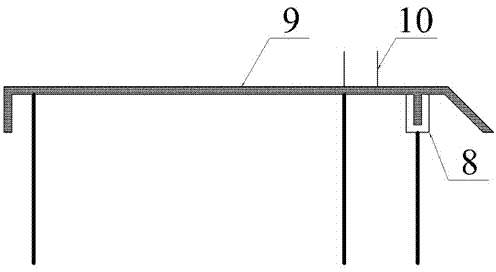

[0022] refer to figure 1 , figure 2 , the integrated high-efficiency autotrophic denitrification reactor of the present invention includes an inner cylinder 2 and an outer cylinder 3 coaxially fixed on the bracket 1, the upper diameter of the outer cylinder 3 is enlarged, and the upper coaxial line of the inner cylinder 2 is sleeved Install the three-phase separator 4 and the trumpet 5 closely connected with the enlarged diameter of the upper part of the outer cylinder wall. The horn 5 divides the space formed by the inner cylinder 2 and the outer cylinder 3 into two parts, wherein the inner side of the horn is between The space between the inner and outer cylinders is an anaerobic zone, the outer side of the trumpet is an annular cone-shaped sedimentation zone, the inner cylinder 2 is used as an aerobic zone, and a vertical deflector 6 is arranged on the upper part of the sedimentation zone, and the three-phase separator 4 is located In the anaerobic zone, there is a mud di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com