A method of using titanium-containing blast furnace slag to improve the sewage treatment performance of constructed wetlands

A technology for constructed wetlands and blast furnace slag, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems such as environmental pollution and waste of valuable resources, and achieve good adsorption performance, sufficient raw materials, Effects that are easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention mainly utilizes the photocatalytic performance of perovskite in the titanium-containing blast furnace slag, the abundant elements beneficial to the growth of wetland plants in the slag, and the high adsorption performance of the titanium-containing blast furnace slag. The photocatalytic principle of perovskite can be described as follows:

[0018] CaTiO 3 +H 2 O→e - + h +

[0019] h + +H 2 O → · OH+H +

[0020] o 2 +e - → · o 2 -

[0021] · o 2 - +H + →HO 2 ·

[0022] 2HO 2 · →O 2 +H 2 o 2

[0023] h 2 o 2 +O 2 - → · OH+OH - +O 2

[0024] h + +OH - → · o

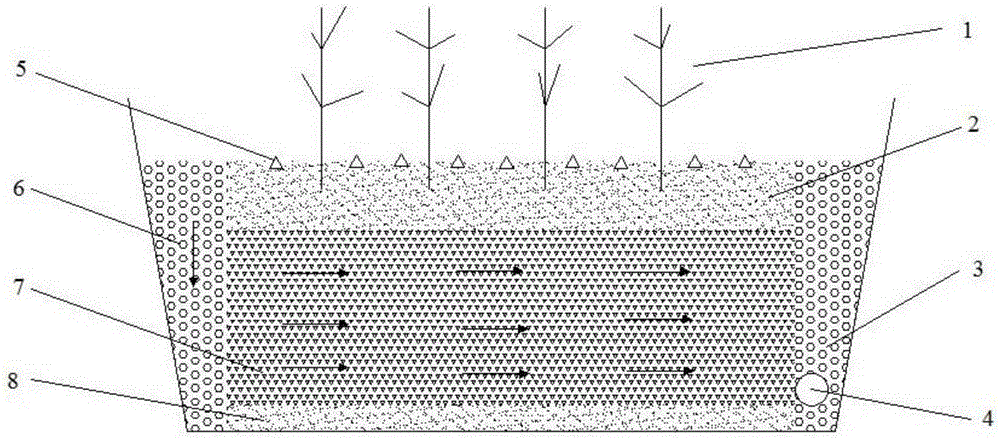

[0025] Such as figure 1 As shown, the constructed wetland sewage treatment system adopts the horizontal subsurface flow constructed wetland model, including soil-slag-powder mixed layer 2, matrix layer 7 containing titanium blast furnace slag filler, wetland plants 1, gravel distribution water area 6, and gravel catchment area 3. Water collection pipe 4 and clay a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com