Synthetic method for 2-butyne-1-ol

A synthesis method and technology for butene are applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., and can solve the problems of shortage of 2-butyn-1-ol, low product purity, and expensive raw materials, etc. Achieve the effect of reducing labor and resources, simple synthesis method, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

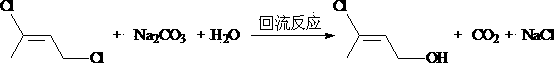

Image

Examples

Embodiment 1

[0023] A kind of synthetic method of 2-butyn-1-alcohol:

[0024] 1. Hydrolysis step

[0025] ⑴. Put 40g of raw materials (recycled rubber production waste liquid, the content of 1,3-dichloro-2-butene is 28.2%), 80ml of water, and 14g of sodium carbonate water into the three-necked flask, heat up and control the temperature After reflux reaction at 89-98°C for 8 hours, sample was taken for analysis.

[0026] (2) When the content of 1,3-dichloro-2-butene is less than 0.5%, stop the reaction, cool down, and extract 3 times with (200ml) ethyl acetate after the reflux reaction, and use (60g) solid calcium carbonate after the extraction Carry out drying, after drying, carry out vacuum distillation to remove ethyl acetate, set the time of vacuum distillation to be 0.5~2h, the temperature of vacuum drying is -0.085MPa.

[0027] (3) Rectification, under 72mmHg, collect the fraction at 78-85°C, cool, and weigh to obtain 9.4g of 3-chloro-2-buten-1-ol, with a yield of 94.2%.

[0028] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com