High-purity Delta terpilenol separation and purification method

An extraction method and technology for terpineol, which are applied in the field of separation and extraction of high-purity delta-terpineol, can solve the problems of low purity of delta-terpineol and difficulty in rectification, and achieve the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

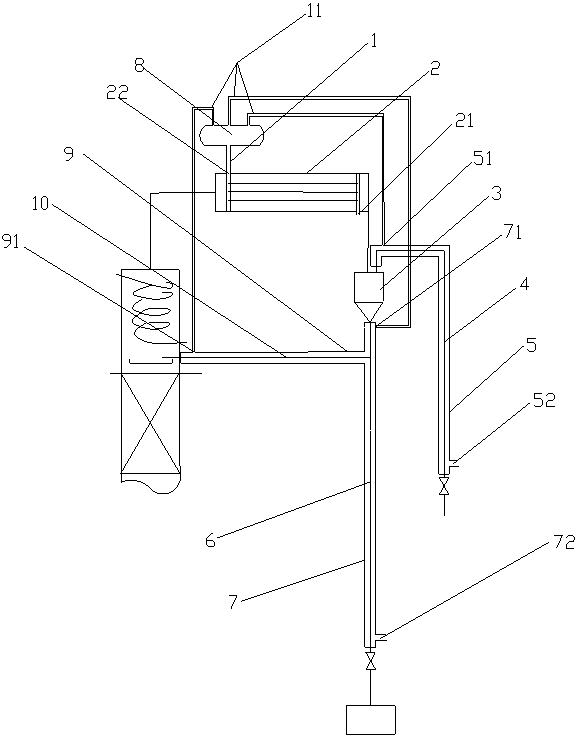

Image

Examples

Embodiment 1

[0020] A method for separating and extracting high-purity delta terpineol, comprising the following steps:

[0021] A. Rectification: Add 3000kg of δ-terpineol raw material into the packed rectification tower, the heating temperature of the tower kettle is 210°C, the temperature of the tower top is 80~150°C, the vacuum degree of the rectification tower is 750mmHg~760 mmHg, heat The final steam keeps rising, and through the cycle process of rectification, condensation, reflux and rectification for many times, according to the different boiling points of the main components in camphor oil (among them, β-caryophyllene 130°C, camphor 204°C, δ-pine oleyl alcohol at 210°C, terpinene-4-ol at 212°C and a-terpineol at 219°C) and collected separately, the reflux ratio was controlled to 800:1, and the fraction at 210±1°C was collected to obtain 500kg of crude δ-pine Oleyl alcohol, the content of δ-terpineol after analysis is 85%;

[0022] B, crystallization: After heating and meltin...

Embodiment 2

[0025] A method for separating and extracting high-purity delta terpineol, comprising the following steps:

[0026] A, rectification: 3000kgδ-terpineol raw material is added in the packed rectification tower, and tower kettle heating temperature is 215 ℃, and the temperature of tower top is 80~150 ℃, and the vacuum degree of rectification tower is 750mmHg~760 mmHg, will The reflux ratio was controlled at 850:1, and the fraction at 210±1°C was collected to obtain 550kg of crude δ-terpineol. After analysis, the content of δ-terpineol was 82.5%;

[0027] B, crystallization: after heating and melting the crude δ-terpineol obtained in step A, mix with ethanol with a concentration of 98% at a mass ratio of 2:5, and crystallize at 8° C. for 4 days after mixing;

[0028] C, centrifugation: add the material after the crystallization is completed in the centrifuge, the centrifuge speed is 1800r / min, let it stand after centrifuging for 10min, collect the crystallization product, repeat s...

Embodiment 3

[0031] A method for separating and extracting high-purity delta terpineol, comprising the following steps:

[0032] A. Rectification: Add 3500kg of δ-terpineol raw material into the packed rectification tower, the heating temperature of the tower kettle is 218°C, the temperature at the top of the tower is 80-150°C, the vacuum degree of the rectification tower is 750mmHg-760 mmHg, heat The final steam rises continuously, and is collected separately according to the boiling points of the main components in the camphor oil through repeated rectification, condensation, reflux, and rectification cycles. The cut of ℃ obtains the thick δ-terpineol of 506kg, and the content of δ-terpineol is 90% after analysis;

[0033] B, crystallization: After heating and melting the crude δ-terpineol obtained in step A, mix it with 90% ethanol at a mass ratio of 1:5, and crystallize at 10° C. for 2 days after mixing;

[0034] C. Centrifugal separation: add the material obtained after crystallizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com