Method for preparing hydroxyl phosphonate

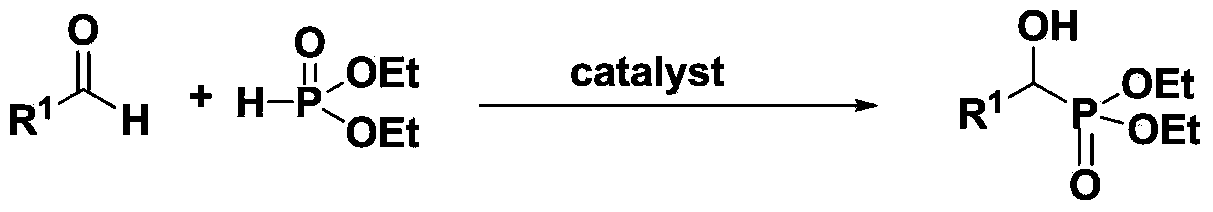

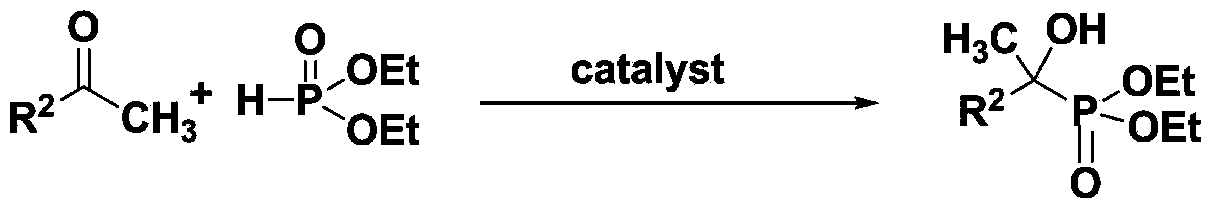

A technology of hydroxyphosphonate and hydrogen phosphine, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., to achieve high yield, mild reaction conditions, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

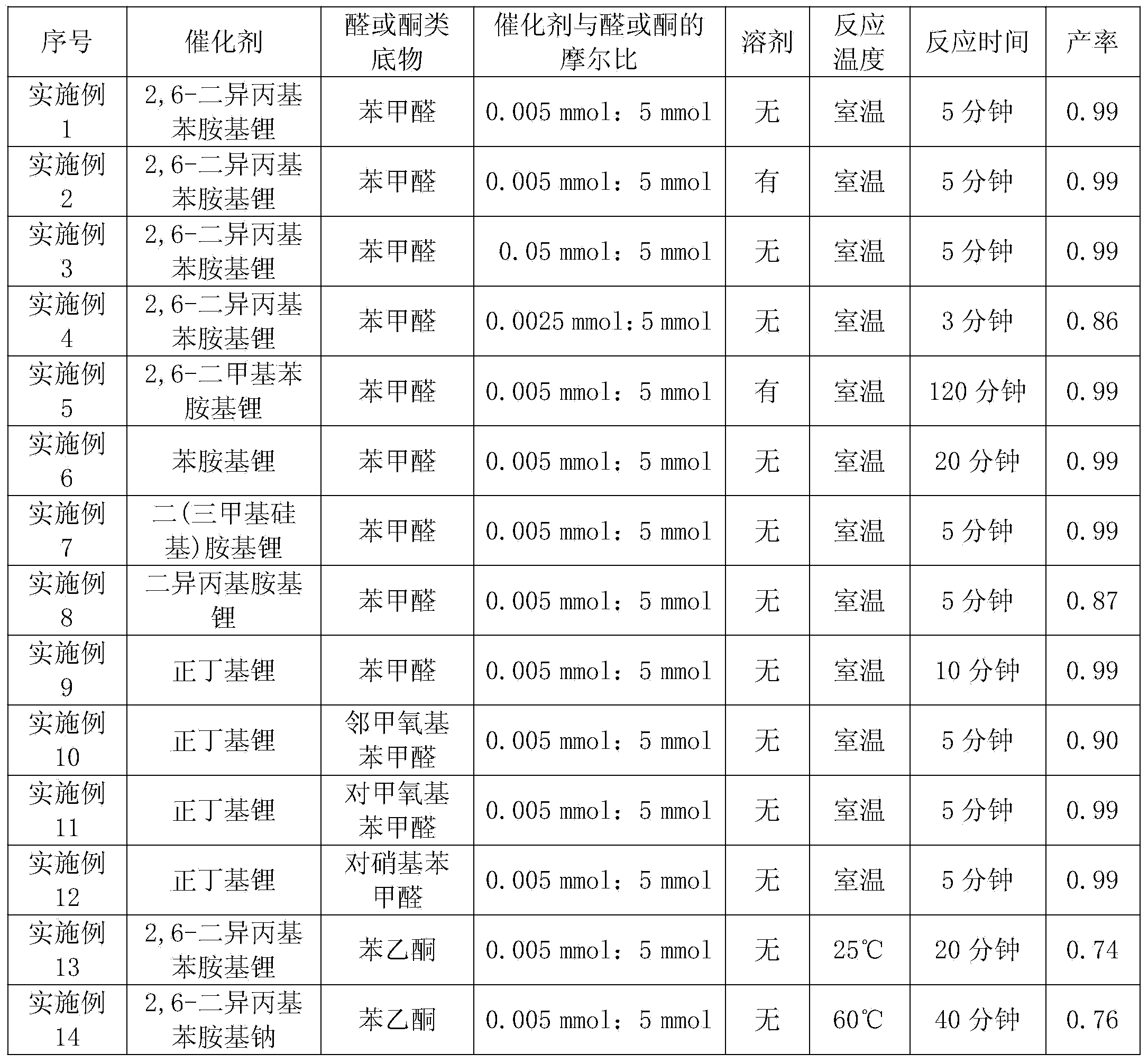

Examples

Embodiment 1

[0033] Example 1: 2,6-Diisopropylanilinide lithium catalyzes the reaction of benzaldehyde and diethyl phosphite

[0034] Under anhydrous, oxygen-free and argon protection, diethyl phosphite (0.77mL, 6mmol) and 2,6-diisopropylanilinidelithium (0.005mmol) were successively added to a 30mL Schlenk reaction flask, and at room temperature After stirring for 10 minutes, benzaldehyde (0.51 mL, 5 mmol) was added, and after reacting at room temperature for 5 minutes, deionized water was added to terminate the reaction. Extracted with ethyl acetate (10mL×3), dried overnight with anhydrous sodium sulfate, filtered, spin-dried, washed with n-hexane to obtain a white solid, dried to constant weight to obtain 1.21 grams of α-hydroxyphosphonate, the calculated yield was 99%.

[0035] The nuclear magnetic analysis for this α-hydroxy phosphonate is as follows: 1 H NMR (CDCl 3 ,400MHz,ppm)δ7.50-7.48(2H,m,ArH),7.37-7.28(3H,m,ArH),5.03-5.00(1H,d,J=10.8Hz,CH),4.08-3.94(4H ,m,CH 2 ), 3.62 (1H,...

Embodiment 2

[0036] Example 2: 2,6-diisopropylanilinide lithium catalyzes the reaction of benzaldehyde and diethyl phosphite

[0037] Under anhydrous, oxygen-free and argon protection, diethyl phosphite (0.77 mL, 6 mmol), 2,6-diisopropylanilinide lithium (0.005 mmol), n-hexane ( 2 mL), stirred at room temperature for 10 minutes, then added benzaldehyde (0.51 mL, 5 mmol), and reacted at room temperature for 5 minutes, then added deionized water to terminate the reaction. Extracted with ethyl acetate (10mL×3), dried overnight with anhydrous sodium sulfate, filtered, spin-dried, washed with n-hexane to obtain a white solid, dried to constant weight to obtain 1.21 grams of α-hydroxyphosphonate, the calculated yield was 99%.

Embodiment 3

[0038] Example Three: 2,6-Diisopropylanilinide Lithium Catalyzed Reaction of Benzaldehyde and Diethyl Phosphite

[0039] Under anhydrous, oxygen-free and argon protection, diethyl phosphite (0.77mL, 6mmol) and 2,6-diisopropylanilinidelithium (0.05mmol) were successively added to a 30mL Schlenk reaction flask, and After stirring for 10 minutes, benzaldehyde (0.51 mL, 5 mmol) was added, and after reacting at room temperature for 5 minutes, deionized water was added to terminate the reaction. Extracted with ethyl acetate (10mL×3), dried overnight with anhydrous sodium sulfate, filtered, spin-dried, washed with n-hexane to obtain a white solid, dried to constant weight to obtain 1.21 grams of α-hydroxyphosphonate, the calculated yield was 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com