Method for synthesizing visible-light response type azobenzene polymer

A synthetic method, azobenzene technology, applied in the field of synthesizing visible light-responsive azobenzene polymers, can solve problems such as limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

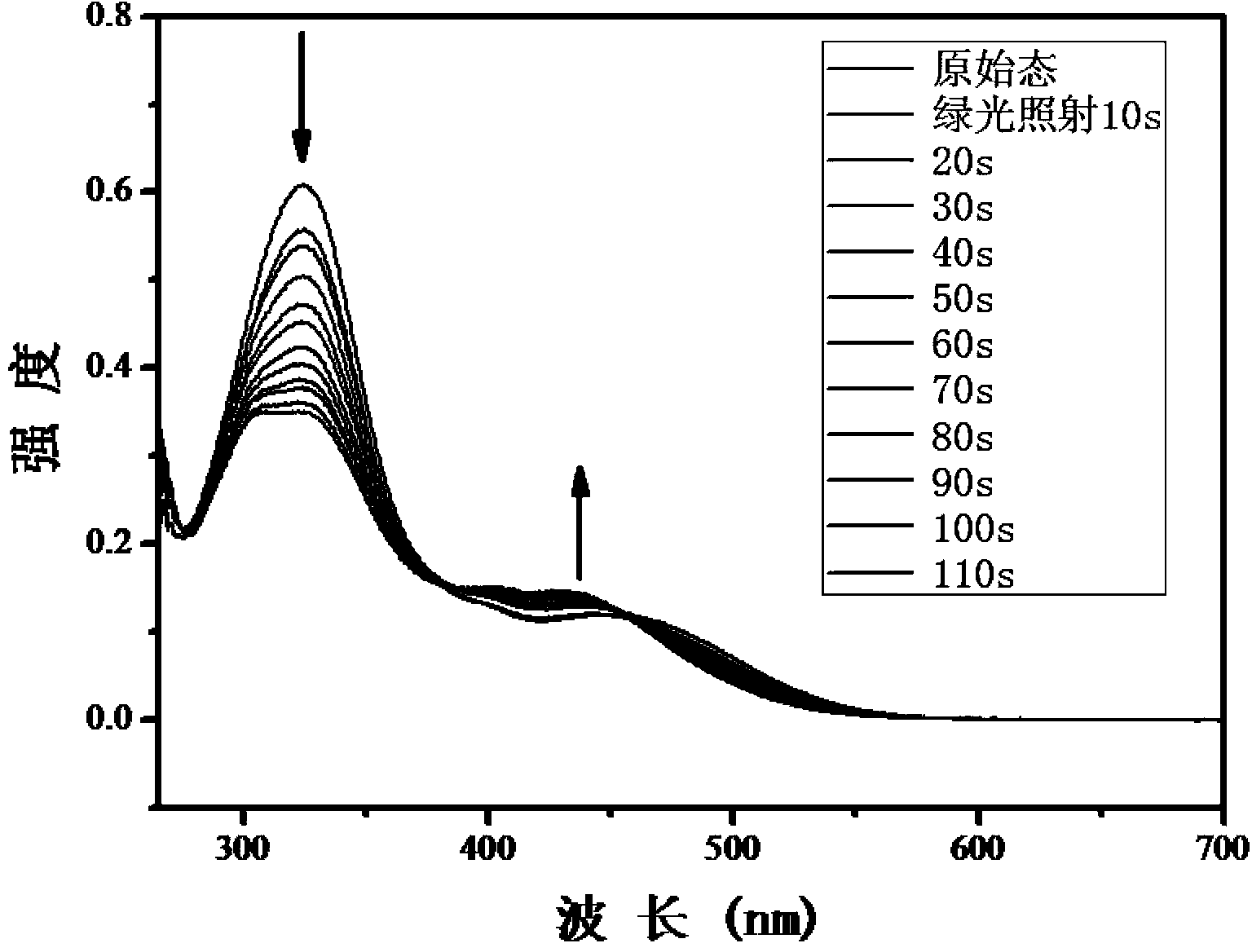

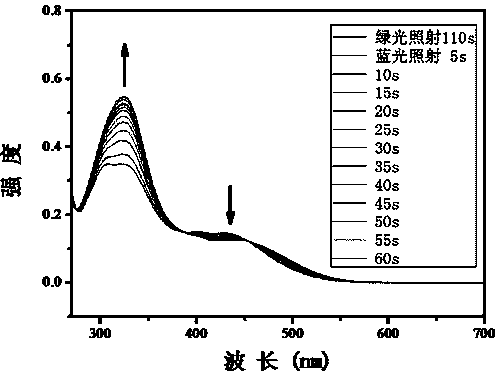

Method used

Image

Examples

Embodiment 1

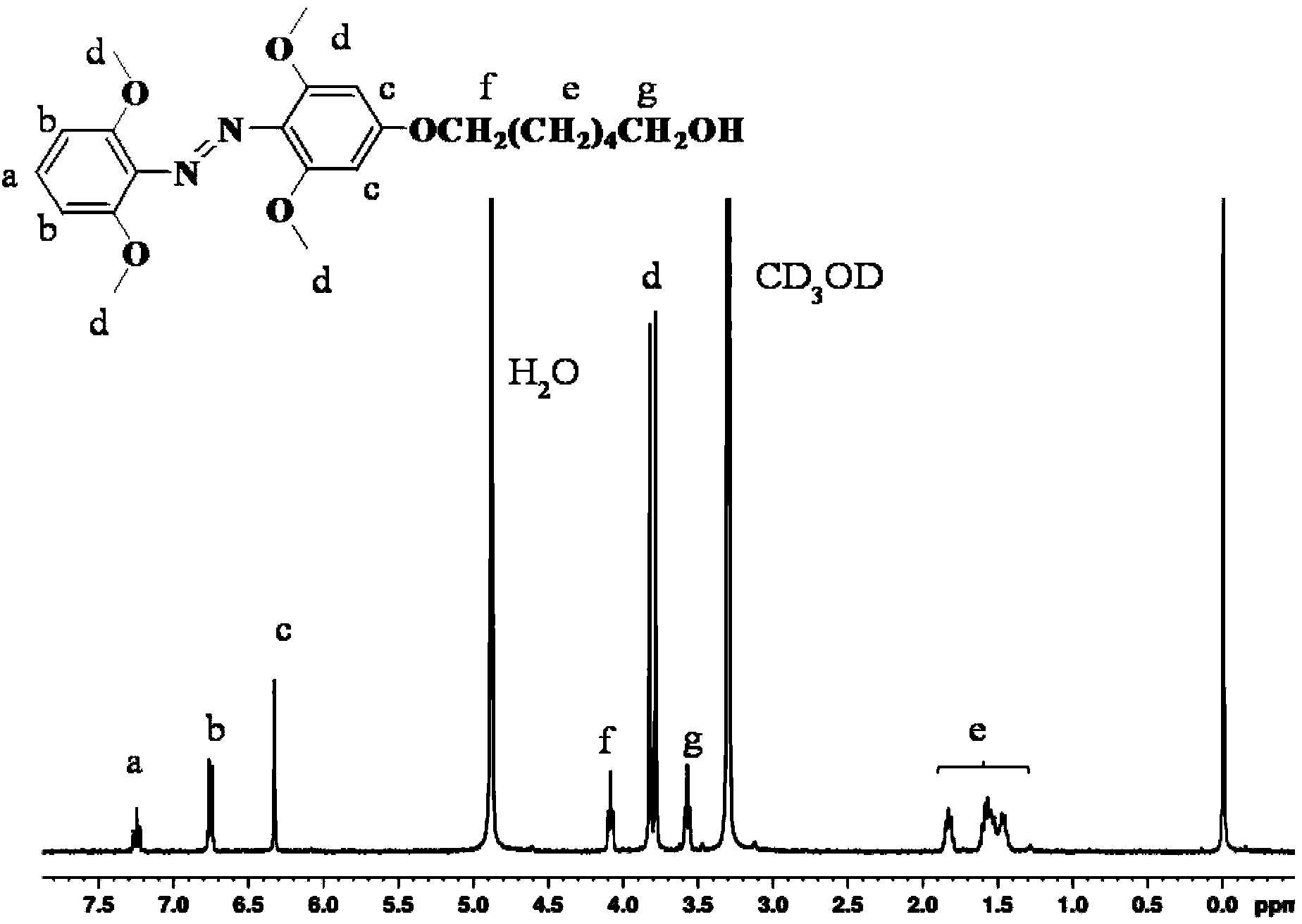

[0026] Preparation of 2,6,2'6'-tetramethoxyazophenol: Dimethoxyaniline (1.53g, 0.01mol), concentrated hydrochloric acid (36%, 2.54ml) and deionized water (3ml) were mixed, Make it into a paste, and control the temperature at about 0°C. Slowly add NaNO dropwise with stirring 2 (0.015mol, 1.035g) 10mL cold aqueous solution. Stir the reaction until the solution makes the starch KI turn blue, filter to obtain the diazonium salt solution; dimethoxyphenol (1.54g, 0.01mol) is dissolved in NaOH (1g, 0.025mol) aqueous solution (10ml); the aforementioned diazonium salt The solution was added dropwise to the phenol solution, and during the dropwise addition, saturated Na 2 CO 3 The solution was adjusted to maintain a pH of 10. After the dropwise addition, continue to stir for 12 h, neutralize with dilute HCl to pH = 6, and stir for 10 min. Suction filtration, the product was washed with deionized water until the filtrate was neutral, and dried.

[0027] Preparation of 2,6,2'6'-tetr...

Embodiment 2

[0031] Preparation of 2,6,2',6'-tetramethoxyazophenol: Dimethoxyaniline (1.53g, 0.01mol), concentrated hydrochloric acid (36%, 3ml) and deionized water (3.5ml) were mixed , into a paste, and the temperature is controlled at about 0°C. Slowly add NaNO dropwise with stirring 2 (0.023mol, 1.55g) 15mL cold aqueous solution. Stir the reaction until the solution makes starch KI turn blue, filter to obtain a diazonium salt solution; dimethoxyphenol (1.54g, 0.01mol) is dissolved in NaOH (1.5g, 0.038mol) aqueous solution (15ml); the aforementioned diazonium The salt solution was added dropwise to the phenol solution. During the dropwise addition, saturated Na 2 CO 3 The solution was adjusted to maintain a pH of 10. After the dropwise addition, continue to stir for 12 h, neutralize with dilute HCl to pH = 6, and stir for 10 min. Suction filtration, the product was washed with deionized water until the filtrate was neutral, and dried.

[0032] Preparation of 2,6,2',6'-tetramethoxy-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com