Preparation method of novel shearing and thickening fluid

A fluid and new technology, applied in the field of preparation of new shear thickening fluids, can solve problems such as waste of raw materials, and achieve the effects of avoiding waste, stable product properties, and less three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Dissolve 5g of tetraneedle-shaped ZnO whiskers in absolute ethanol at a mass ratio of 1:40, stir for 45min at 2000r / min, then filter the mixture into a filter cake, and place the filter cake at 110 Dry in an oven at ℃ for 2 hours for later use;

[0025] (2) Add 0.05g, 0.10g, 0.15g and 0.20g of the above powders into 90g of polyethylene glycol with a molecular weight of 200, stir for 1 hour under the condition of 2000r / min with a magnetic stirring device, and then use a 240W power Ultrasonic dispersion in ultrasonic cleaning device for 5h, and finally stand for 6h.

[0026] (3) Take 10g of silicon dioxide micro-nano powder and add it to the above system, continue to mechanically stir for 2h, and then use PM100 ball milling equipment to continue to disperse at 100r / min for 2h. Vacuumize for 1 hour to remove air bubbles in the system, and let it stand for 1 hour to finally obtain 4 kinds of shear thickening fluids.

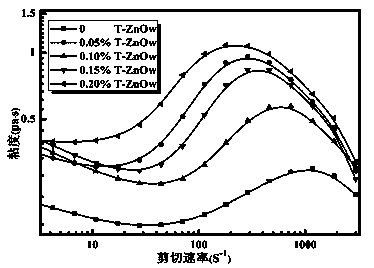

[0027] The steady-state rheological curves of four...

Embodiment 2

[0029] (1) Dissolve 5g of tetraneedle-shaped ZnO whiskers in absolute ethanol at a mass ratio of 1:50, stir for 60min at 2000r / min, then filter the mixture into a filter cake, and place the filter cake at 110 Dry in an oven at ℃ for 3 h.

[0030] (2) Add 0.20 g of the above powder into 85 g of polyethylene glycol with a molecular weight of 400, and stir for 1 h with a magnetic stirring device at 2000 r / min , Then ultrasonically disperse for 4 hours in a 240W power ultrasonic cleaning device, and finally stand still for 7 hours.

[0031] (3) Take 15g of silicon dioxide micro-nano powder and add it to the above system, continue to mechanically stir for 2h, and then use PM100 ball milling equipment to continue to disperse at 100r / min for 2h. Vacuumize for 1 hour to remove air bubbles in the system, let stand for 1 hour, and finally obtain a shear thickening fluid.

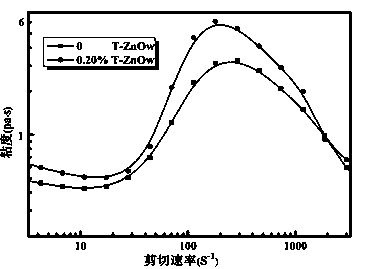

[0032] The steady-state rheological curve of a shear-thickening fluid is image 3 shown. It can be seen from th...

Embodiment 3

[0034] (1) Dissolve 5g of tetraneedle-shaped ZnO whiskers in absolute ethanol at a mass ratio of 1:40, stir for 55min at 2000r / min, then filter the mixture into a filter cake, and place the filter cake at 110 Dry in an oven at ℃ for 2 hours for later use;

[0035] (2) Add 0.05g, 0.10g, 0.15g and 0.20g of the above powders into 80g polyethylene glycol 200 respectively, and stir for 1 hour under the condition of 2000r / min with a magnetic stirring device , Then ultrasonically disperse for 5 hours in a 240W power ultrasonic cleaning device, and finally stand still for 8 hours.

[0036] (3) Take 20g of silicon dioxide micro-nano powder and add it to the above system, continue to mechanically stir for 2h, and then use PM100 ball milling equipment to continue to disperse at 100r / min for 2h. Vacuumize for 1 hour to remove air bubbles in the system, and let it stand for 1 hour to finally obtain 4 kinds of shear thickening fluids.

[0037] The steady-state rheological curves of four k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com