Optimum design method of upflow type anaerobic fermentation biological hydrogen production reactor and application thereof

A hydrogen production reactor, up-flow anaerobic technology, applied in the field of environmental engineering, can solve the problems of limited parameter basis, difficult parameter optimization selection, time and economy not allowed, etc., to achieve the effect of optimal design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Taking an upflow anaerobic fermentation biological hydrogen production reactor with an effective volume of 3.35 liters as an example to carry out the process of optimizing the hydraulic flow field, the specific operations are as follows:

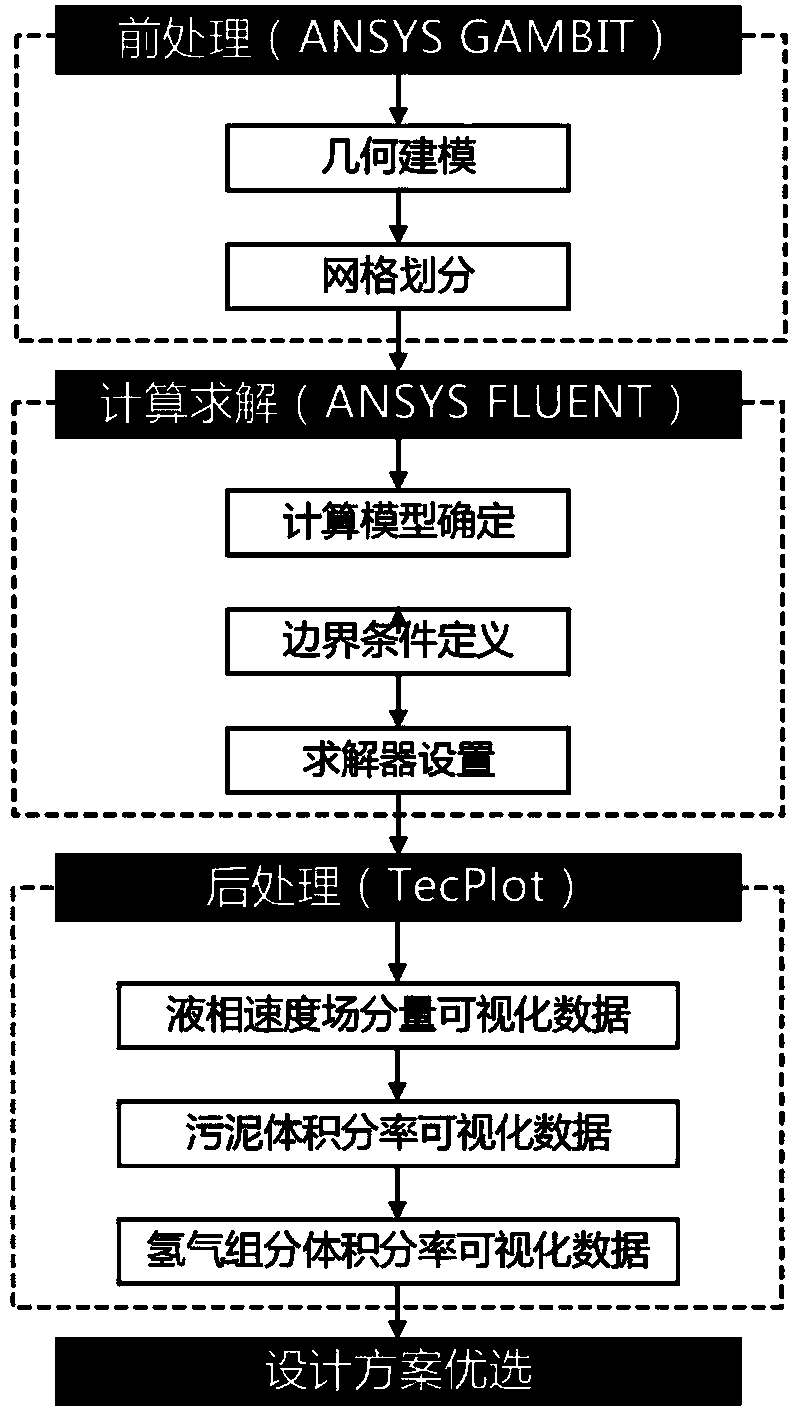

[0094] (1) Preprocessing: geometric modeling and meshing

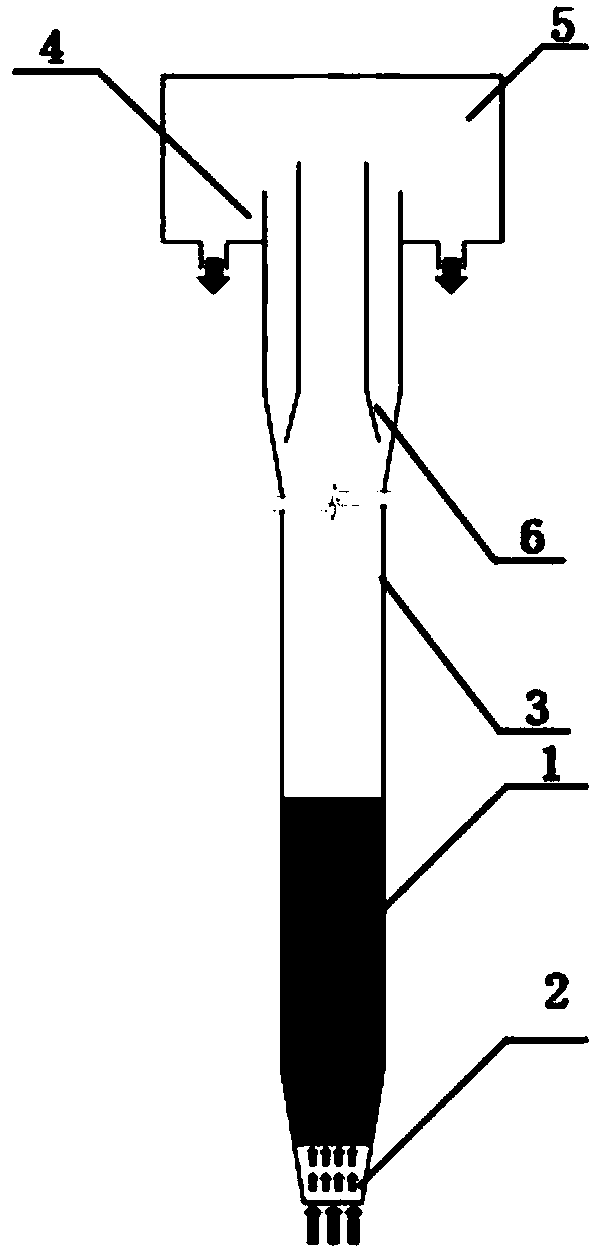

[0095] According to the actual geometric size of the up-flow anaerobic fermentation bio-hydrogen production reactor (such as figure 2 As shown in the schematic diagram), ANSYS GAMBIT 2.4.6 is used to carry out geometric modeling and grid division of the reactor. During the modeling process, the thickness of the three-phase separation baffle and overflow baffle of the reactor is ignored, and it is approximated as a thin surface structure.

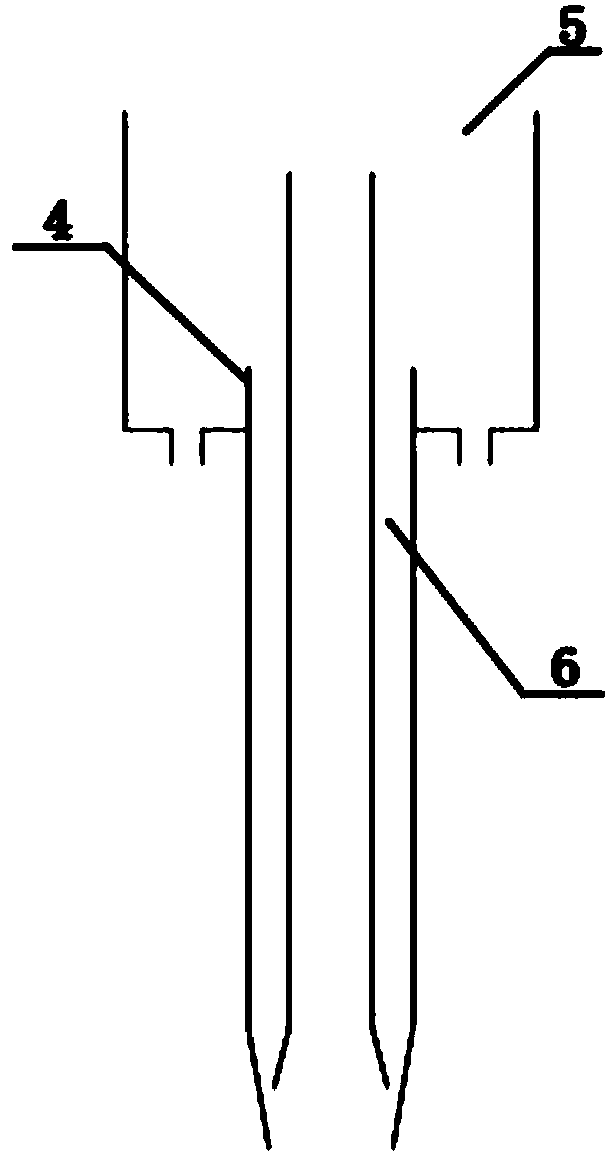

[0096] During the meshing process, the image 3 with Figure 4 The unstructured tetrahedral grid generation method is shown, and the grid points near the wall in the two calculation domains of the water intake area and the three-phase se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com