Patterning method for graphene film

A graphene film and patterning technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of excessive environmental equipment requirements, inability to use large-scale production, and poor effect of patterning methods, etc., to achieve production Low cost, elimination of adverse effects, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

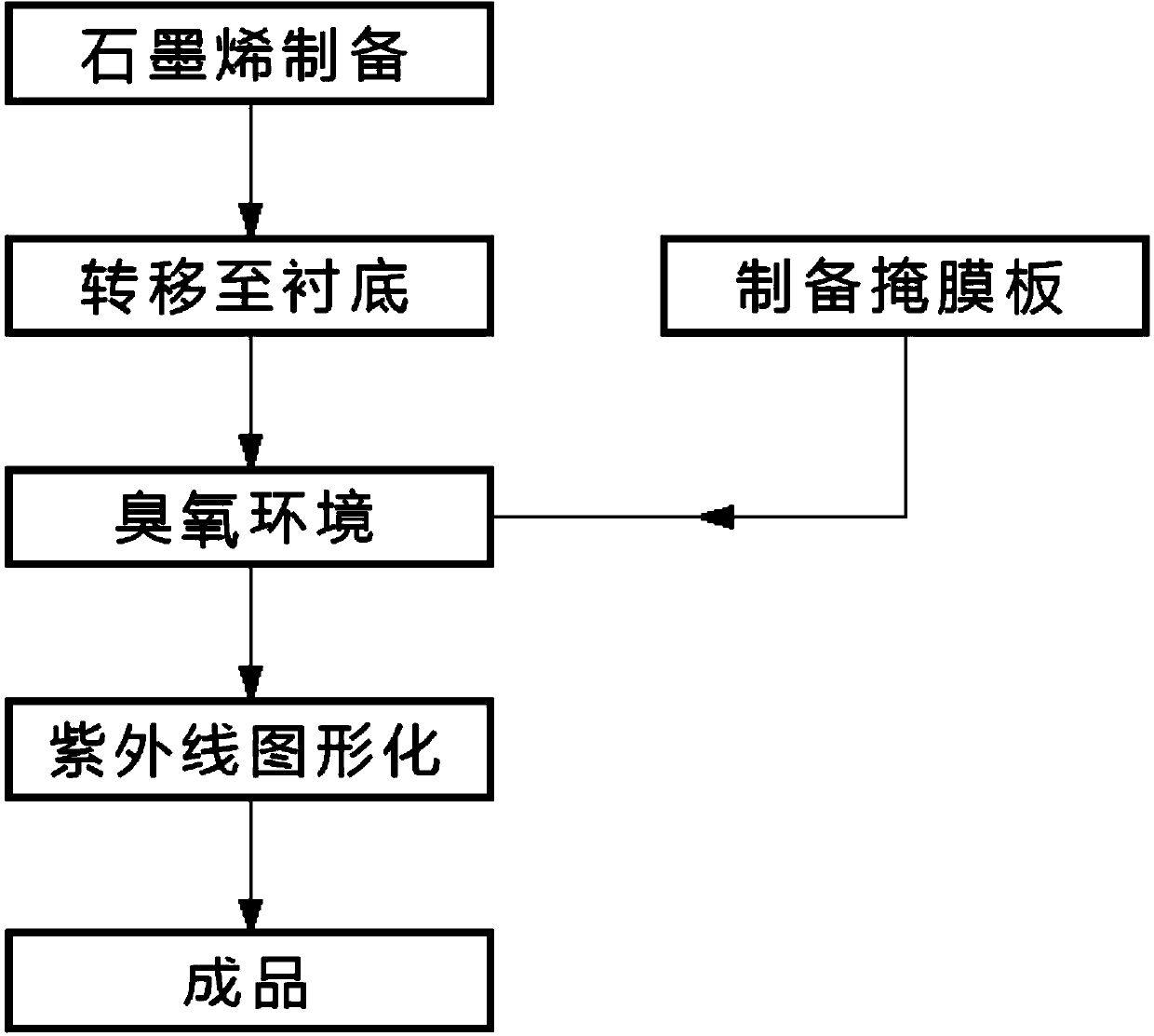

[0028] The patterning method of the graphene thin film of the present embodiment comprises the following steps:

[0029] 1), preparing a graphene film and transferring it to a substrate;

[0030] Firstly, a chemical vapor deposition method is used to grow a graphene film on a metal film, and the metal film is copper foil, aluminum foil or nickel foil; then the obtained graphene film is transferred to a PET film substrate.

[0031] 2), making a graphene mask;

[0032] A mask is prepared according to the desired pattern, and the mask in this embodiment is a hollowed-out tinfoil mask.

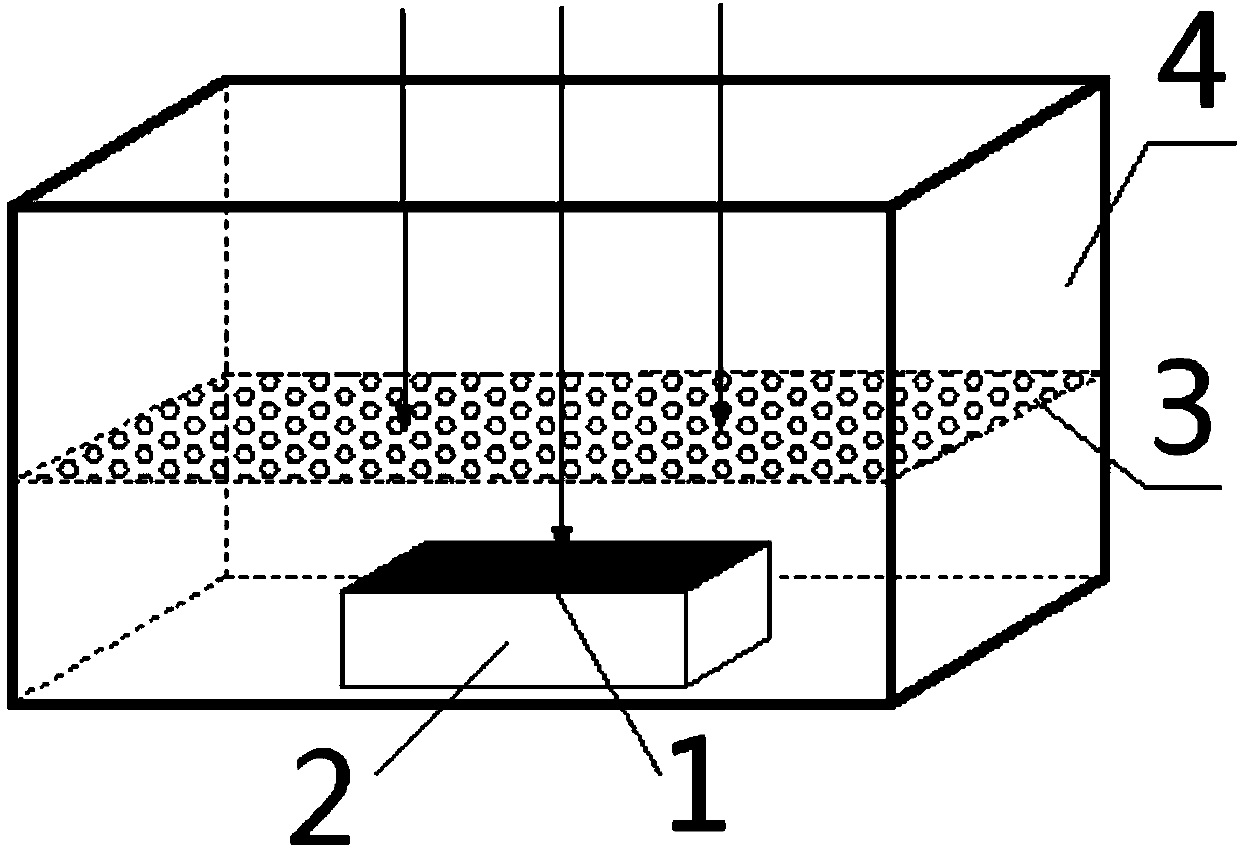

[0033] 3), the graphene mask plate and the graphene film are placed in an ozone environment;

[0034] When placing, pay attention to placing the mask plate between the graphene film and the ultraviolet light source.

[0035] 4) Graphicalization: turn on the ultraviolet light source and graphene film; figure 2 It is a schematic diagram of the graphical processing steps of the present embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com