Catalyst for preparing low carbon olefin from synthetic gas and application thereof in Fischer-Tropsch reaction

A technology of low-carbon olefins and catalysts, which is applied in the field of preparation of Fischer-Tropsch synthesis catalysts, can solve the problems of ineffective suppression of methane, and achieve the effects of easy operation, single component and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

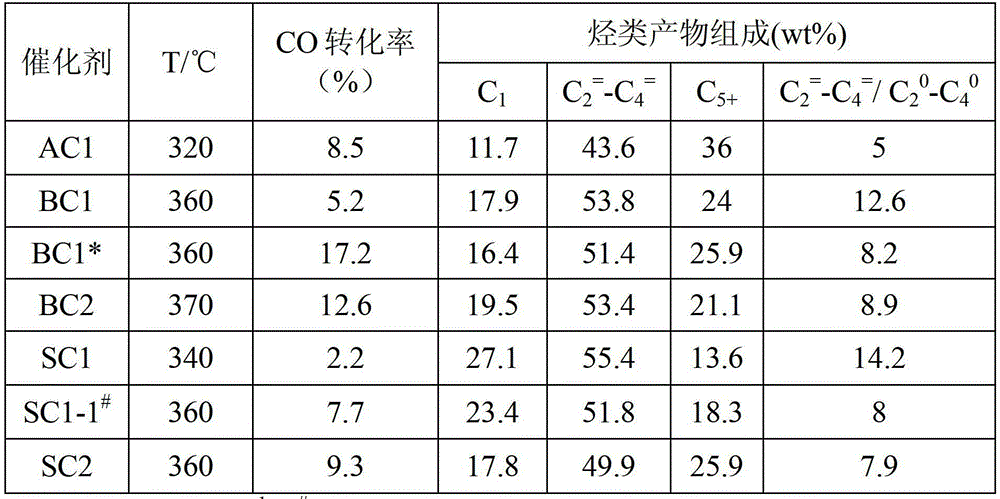

[0025] Take 0.978g of activated carbon baked at 110°C for 12h, add 1.62g of 7wt% iron (NH 4 ) 4 Fe(CN) 6 The aqueous solution was added to the activated carbon, stirred evenly, and vacuum-dried at room temperature for 24 hours, the catalyst was pressed and sieved at 6 MPa, and a sample of 40-60 mesh was taken to obtain an AC1 catalyst with an iron loading of 11.6%.

Embodiment 2

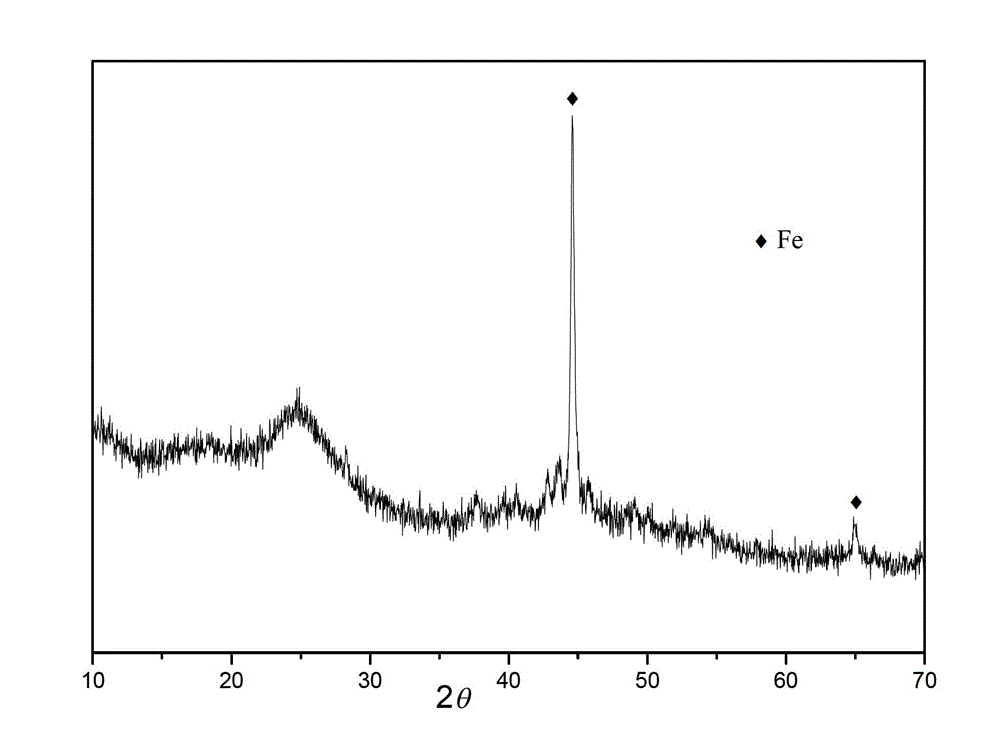

[0027] Treat 5g of carbon black in 50ml of 15% hydrogen peroxide at 100°C for 7 hours, wash and filter with suction, and dry in an oven at 110°C. Get the carbon black of 0.315g above-mentioned drying, with 0.375ml iron content be 7wt% (NH 4 ) 4 Fe(CN) 6 The aqueous solution was diluted and impregnated into the carbon black twice with equal volume, and after stirring uniformly each time, it was vacuum-dried at room temperature for 4 hours. The obtained catalyst was pressed and sieved at 6 MPa, and a sample of 40-60 mesh was taken to obtain a BC1 catalyst with an iron loading of 9.6%. After the catalyst was reduced by hydrogen, the XRD of the sample was as follows: figure 1 shown.

Embodiment 3

[0029] Get 0.304g with the carbon black of above-mentioned treatment, with 0.525ml iron content be 7wt% (NH 4 ) 4 Fe(CN) 6 The aqueous solution was diluted with water and then added to the carbon black in two equal volumes, stirred uniformly each time, and then vacuum-dried at room temperature for 4 hours. The obtained catalyst was pressed and sieved at 6MPa, and a 40-60 mesh sample was taken to obtain a BC2 catalyst with an iron loading of 13.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com