Preparation method of porous carbon microspheres

A technology of porous carbon and microspheres, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of large-scale production difficulties by hydrothermal method, poor quality of microspheres, etc., and achieve uniform morphology and uniform particle size. , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

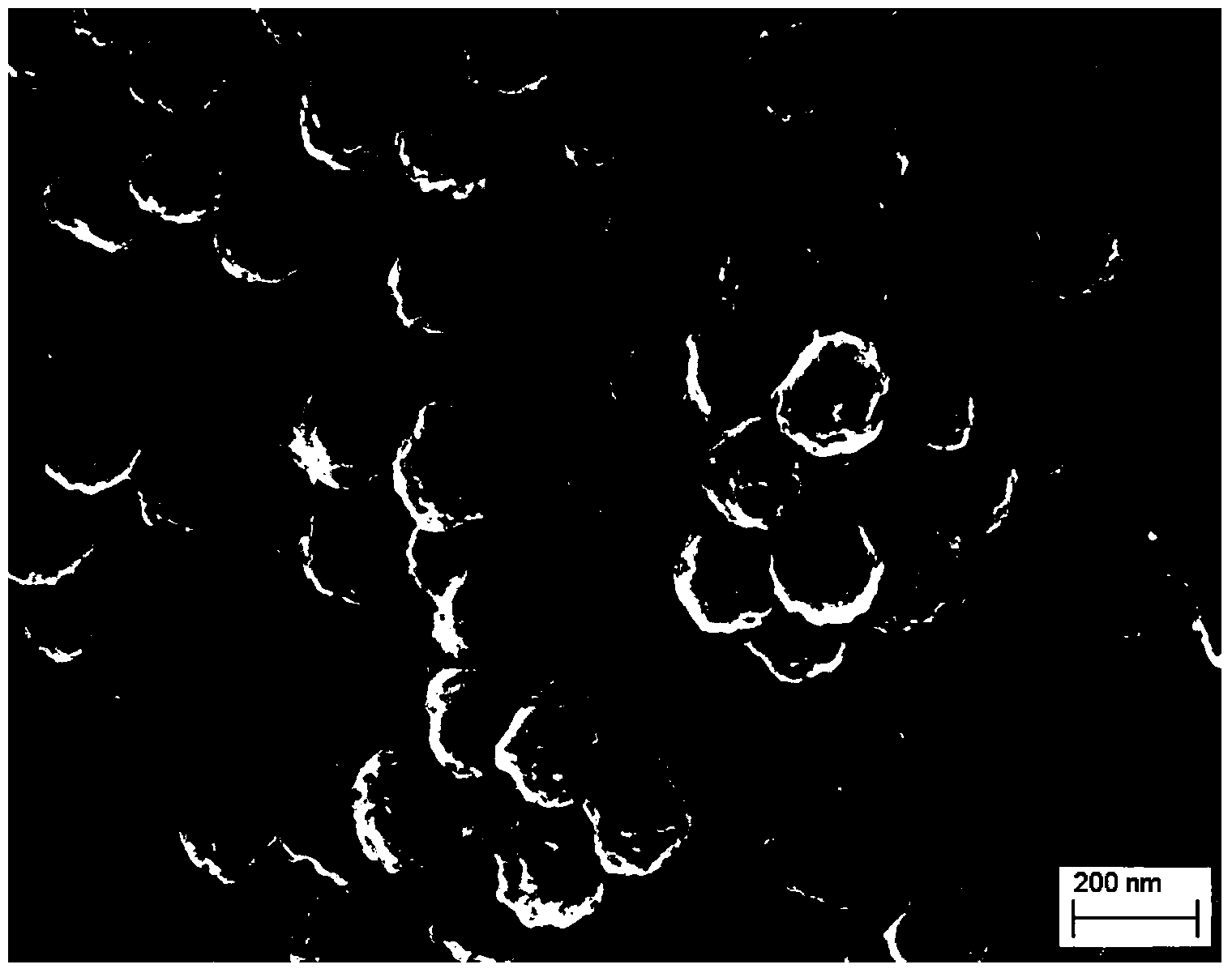

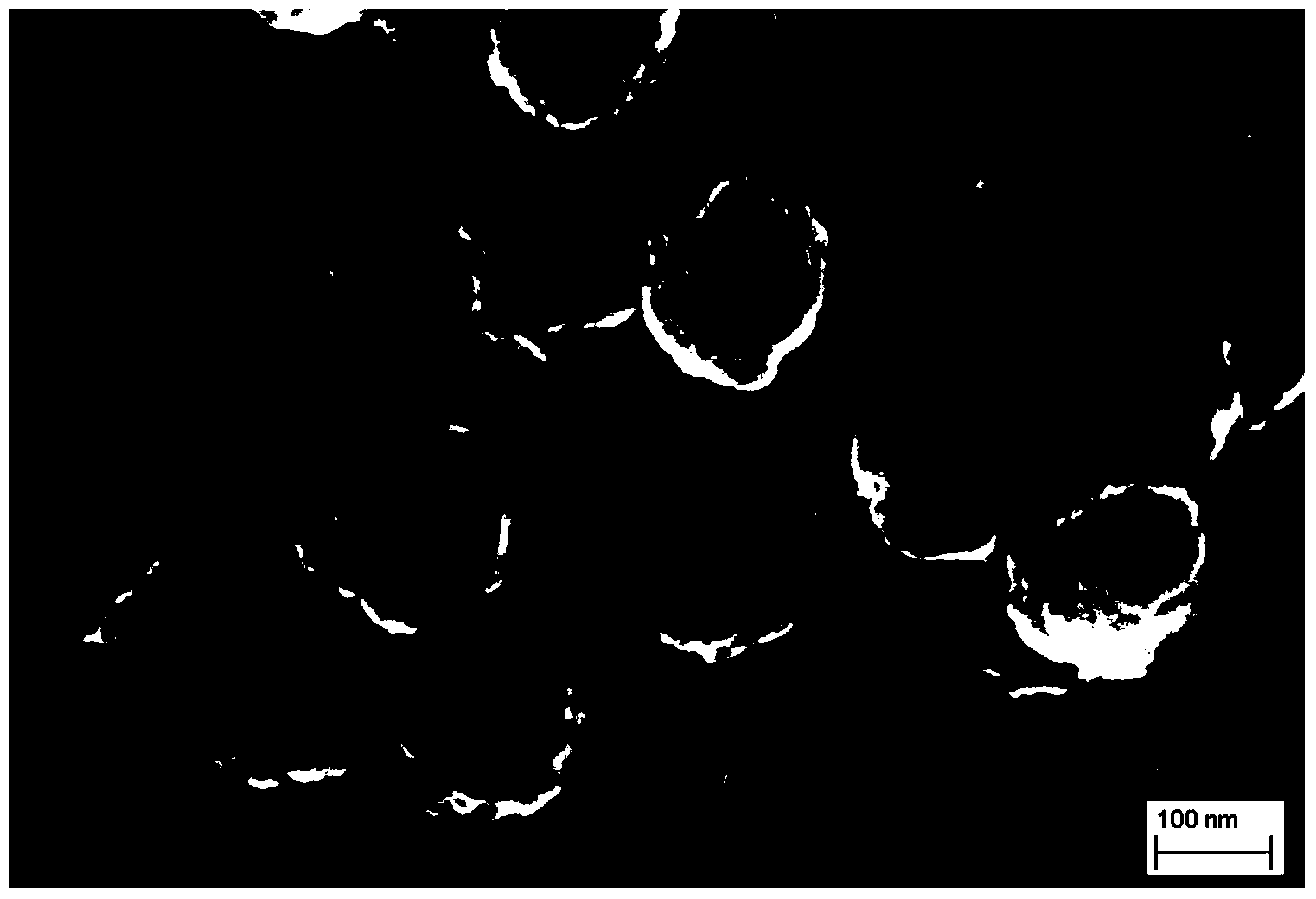

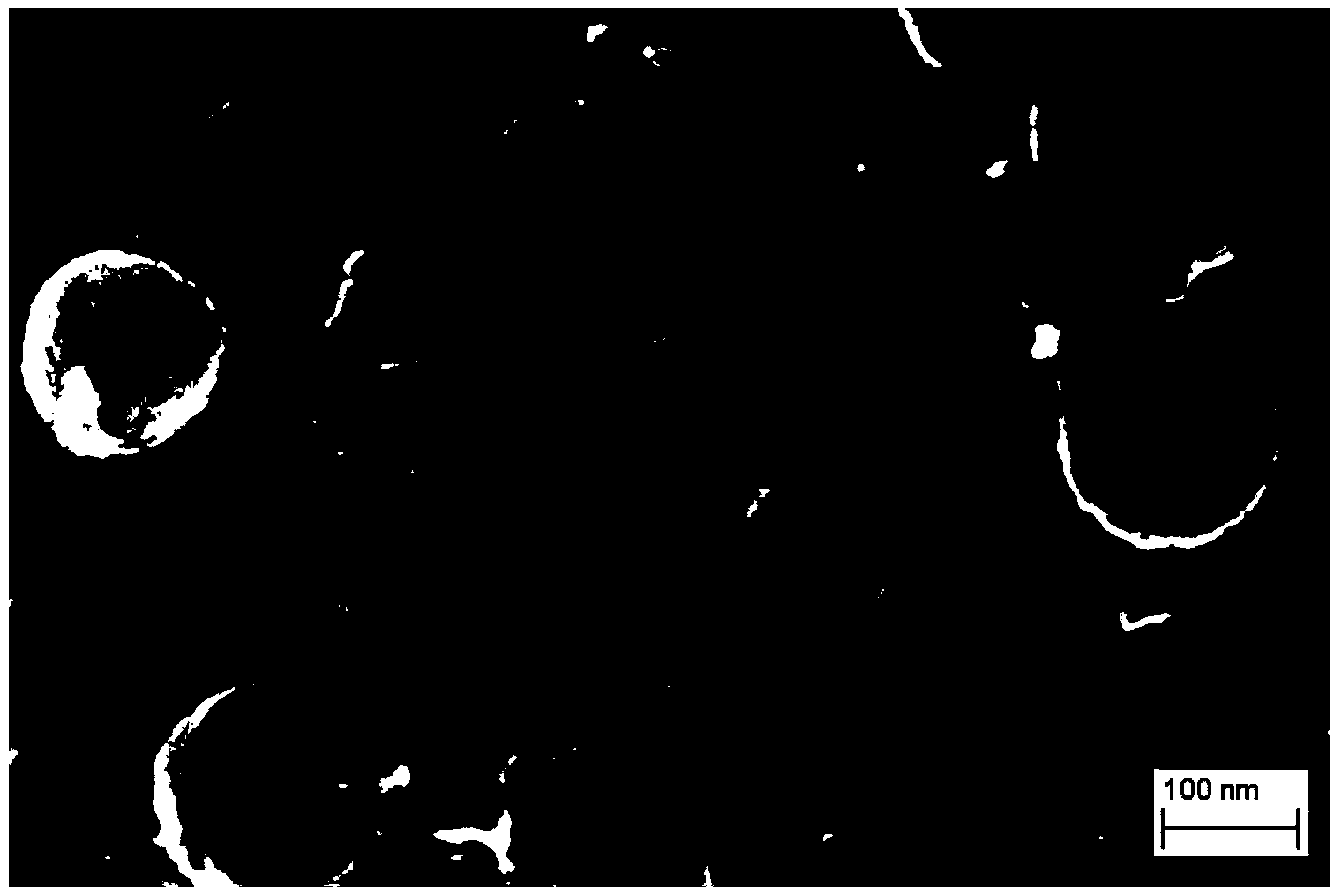

[0023] Preparation of carbon microspheres. Weigh 3.88g resorcinol, 5.2ml formaldehyde, mix and stir for 1 hour, add 30ml deionized water, mix and stir for 2 hours to form a uniform carbon precursor solution, measure 15ml polymer hollow microspheres, stir and mix at room temperature for 24 hours hour. Centrifugal cleaning, adding 1ml of acetic acid at 80°C for curing for 24 hours.

[0024] Dry at 60°C, put the powder in a high-temperature atmosphere furnace, pass argon gas at a rate of 0.1L / min, heat up to 100°C at a rate of 5K / min, and keep it warm for 2 hours. Then the temperature was raised to 420°C at a rate of 5K / min for 3 hours, and then the temperature was raised to 800°C at a rate of 5K / min, and the temperature was kept for 4 hours, and activated by carbon dioxide for 2 hours to obtain carbon microspheres.

Embodiment 2

[0026] Preparation of carbon microspheres. Weigh 3.88g resorcinol, 5.2ml formaldehyde, mix and stir for 1 hour, add 30ml of deionized water, mix and stir for 2 hours to form a uniform carbon precursor solution, measure 15ml of polymer hollow microspheres, stir and mix and place at room temperature for 48 hour. Centrifugal cleaning, adding 1ml of acetic acid at 40°C and curing for 24 hours.

[0027] Dry at 60°C, put the powder in a high-temperature atmosphere furnace, pass argon gas at a rate of 0.1L / min, heat up to 100°C at a rate of 5K / min, and keep it warm for 2 hours. Then the temperature was raised to 420°C at a rate of 5K / min for 3 hours, and then the temperature was raised to 900°C at a rate of 5K / min for 3 hours, and activated by carbon dioxide for 1 hour to obtain carbon microspheres.

Embodiment 3

[0029] Preparation of carbon microspheres. Weigh 3.88g resorcinol, 5.2ml formaldehyde, mix and stir for 1 hour, add 30ml deionized water, mix and stir for 2 hours to form a uniform carbon precursor solution, measure 15ml polymer hollow microspheres, stir and mix at room temperature for 24 hours hour. Centrifugal cleaning, adding 1ml of acetic acid at 60°C for curing for 24 hours.

[0030] Dry at 60°C, put the powder in a high-temperature atmosphere furnace, pass argon gas at a rate of 0.1L / min, heat up to 100°C at a rate of 5K / min, and keep it warm for 2 hours. Then the temperature was raised to 420°C at a rate of 5K / min for 3 hours, and then the temperature was raised to 1000°C at a rate of 5K / min for 3 hours, and activated by carbon dioxide for 1 hour to obtain carbon microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com