Device and method for preparing aluminum oxide by roasting crystalline aluminum chloride hexahydrate in rotary kiln

A technology for crystallizing aluminum chloride and aluminum chloride hexahydrate, which is applied in the preparation of alumina/hydroxide, etc., can solve the problems that the process technology and roasting equipment are not mature and widely used, and achieve the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

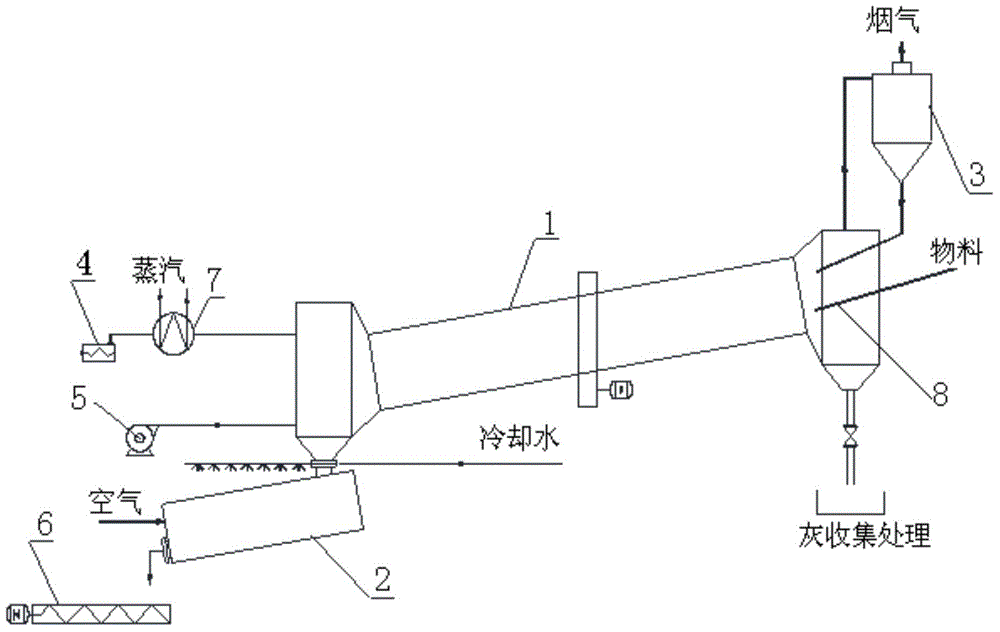

[0020] like figure 1 As shown, a device for preparing alumina by roasting crystalline aluminum chloride hexahydrate in a rotary kiln according to the present invention includes a roasting rotary kiln 1, a cooling kiln 2, a cyclone separator 3, a heavy oil pump 4, a combustion-supporting fan 5, a belt Packaging machine 6 and heavy oil heater 7;

[0021] Among them, the kiln head of the roasting rotary kiln 1 is connected to the combustion-supporting fan 5 and the heavy oil heater 7 through pipelines, the combustion-supporting fan 5 is used to provide air, and the heavy oil heater 7 is used to provide heated heavy oil; the roasting rotary kiln 1 The feeding port at the bottom of the kiln head is connected to the cooling kiln 2; the outlet of the cooling kiln 2 is connected to the belt packaging machine 6;

[0022] The kiln tail part of the roasting rotary kiln 1 communicates with the bottom inlet of the cyclone separator 3 and the feeding pipe 8;

[0023] The upper flue gas in...

Embodiment 2

[0027] Adopt the rotary kiln roasting of device described in embodiment 1 to prepare the method for aluminum oxide by roasting hexahydrate crystalline aluminum chloride, it comprises the steps:

[0028] (a) Heavy oil (for example: No. 200 heavy oil or other grades of heavy oil) is pressurized by the heavy oil pump 4 to 1.2 ~ 1.6MPa.g (for example: 1.2MPa.g, 1.4MPa.g or 1.6MPa.g) in the heavy oil heater In 7, after being heated by steam heat exchange, it enters the kiln head of the roasting rotary kiln 1, mixes and burns with the air from the self-combustion fan 5 to form flue gas, and forms a temperature of 1100-1300°C at the kiln head of the roasting rotary kiln 1 (for example, : 1100°C, 1200°C or 1300°C) stable temperature field;

[0029] (b) The aluminum chloride hexahydrate crystal material to be roasted is sent into the roasting rotary kiln 1 through the feed pipe 8 from the kiln tail position of the roasting rotary kiln 1; During the movement of the kiln head, the alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com