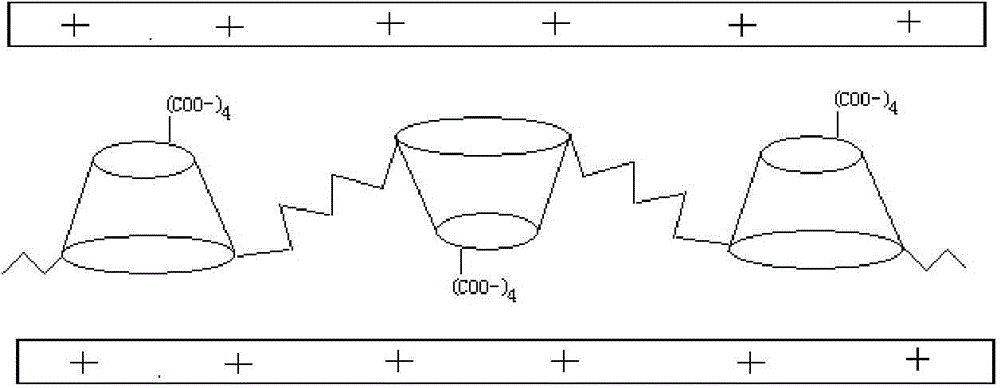

Carboxymethyl-beta-cyclodextrin polymer intercalated hydrotalcite material and preparation method thereof

A technology of cyclodextrin polymer and carboxymethyl, which is applied in the direction of iron oxide/iron hydroxide, cobalt oxide/cobalt hydroxide, etc., to achieve the effect of simple and easy preparation method, large application field and high reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

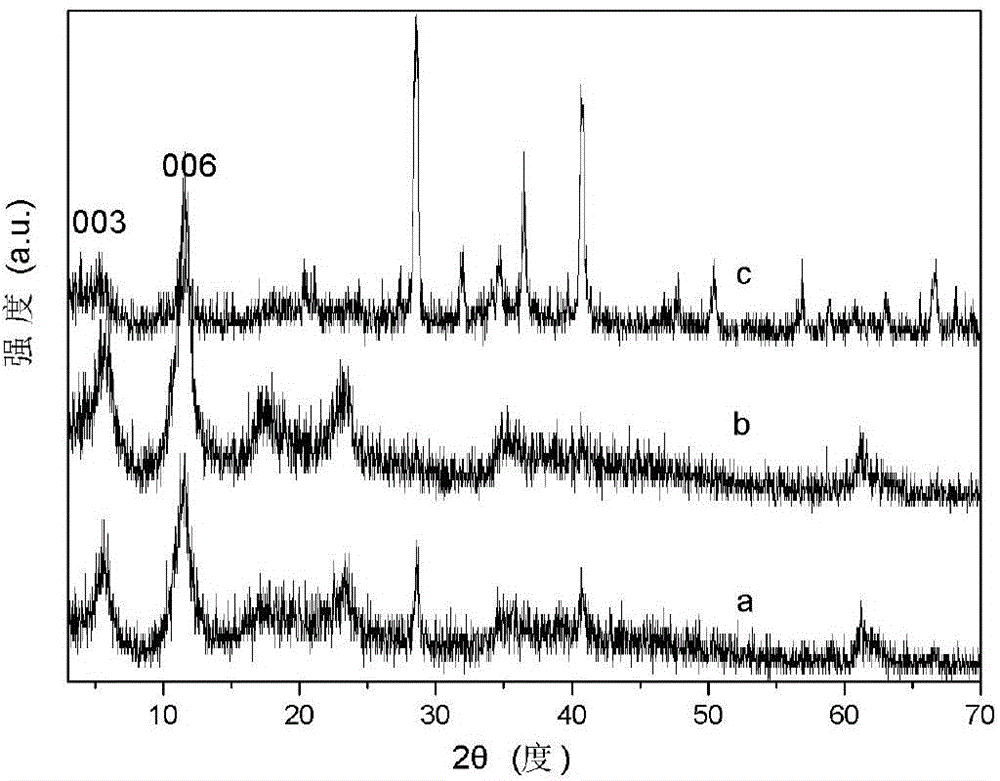

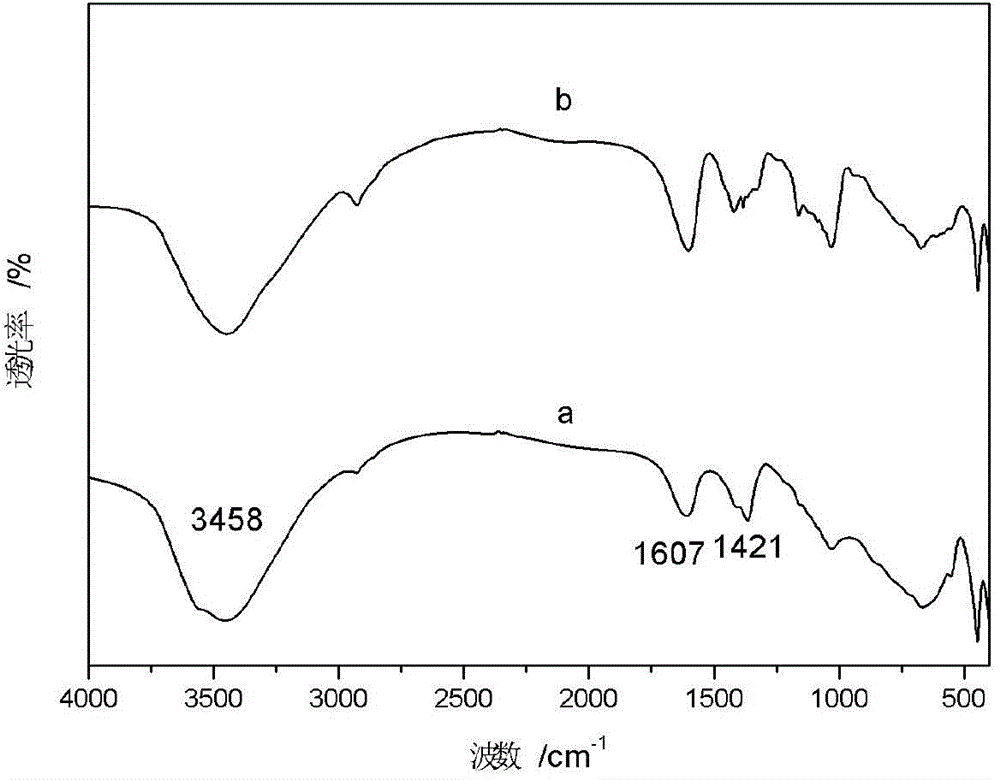

Embodiment 1

[0039] Step A: take by weighing 11.64g Co(NO 3 ) 2 ﹒ 6H 2 O, 8.08g Fe(NO 3 ) 3 ﹒ 9H 2 Dissolve O in 100ml to remove CO 2 Prepare a mixed salt solution in deionized water, and dissolve another 5.60g NaOH in 50ml to remove CO 2 Alkaline solution prepared in deionized water, at room temperature N 2 Protection Add the mixed salt solution and alkali solution into the four-necked flask by double-drop method, and stir at a stirring speed of 600 rpm. Adjust the pH value to 8 with 0.2mol / L NaOH solution. The resulting slurry was crystallized at 60 °C for 72 h, then the precipitate was filtered, and the CO 2 Washing with water several times until the pH of the washing solution = 7, the hydrotalcite precursor NO 3 -LDHs, whose Co 2+ / Fe 3+ =2.

[0040] Step B: Dissolve 1.0 g of carboxymethyl-β-cyclodextrin (CMCD) solid in 100 mL to remove CO 2 After the deionized water is transferred to the four-necked bottle, add the hydrotalcite precursor NO which is filled with 15.0g st...

Embodiment 2

[0045] Step A: Weigh 9.52g CoCl 2 ﹒ 6H 2 O, 5.40g FeCl 3 ﹒ 6H 2 Dissolve O in 100ml to remove CO 2 deionized water to prepare a mixed salt solution, and another 8.00g NaOH was dissolved in 50ml to remove CO 2 Prepare alkaline solution in water, N at room temperature 2 Protection: Add the salt solution and the alkali solution into the four-necked flask by the double-drop method, and stir at 600 rpm. Adjust the pH value to 10 with 1.0mol / L NaOH solution. The resulting slurry was crystallized at 80 °C for 24 h, then the precipitate was filtered, and the CO 2 Washing with water several times until the pH of the washing solution = 7, the hydrotalcite precursor Cl-LDHs, its Co 2+ / Fe 3+ =2.

[0046] Step B: Dissolve 1.0 g of carboxymethyl-β-cyclodextrin (CMCD) solid in 100 mL to remove CO 2 Transfer the deionized water into the four-necked bottle, and then add the hydrotalcite precursor Cl-LDHs obtained in step A containing 14.0g, N 2 Protected and heated to 80°C, react...

Embodiment 3

[0051] Step A: take by weighing 11.64g Co(NO 3 ) 2 ﹒ 6H 2 O,5.37g Fe(NO 3 ) 3 ﹒ 9H 2 Dissolve O in 100ml to remove CO 2 deionized water to prepare a mixed salt solution, and another 5.60g NaOH was dissolved in 50ml to remove CO 2 Prepare alkaline solution in water, N at room temperature 2Protection The salt solution and the alkali solution were added into the four-necked flask by the double-drop method, and stirred at a stirring speed of 600 rpm. Adjust the pH value to 9 with 0.5mol / L NaOH solution. The resulting slurry was crystallized at 70 °C for 48 h, then the precipitate was filtered, and the CO 2 Washing with water several times until the pH of the washing solution = 7, the hydrotalcite precursor NO 3 -LDHs, whose Co 2+ / Fe 3+ =3.

[0052] Step B: Dissolve 1.0 g of carboxymethyl-β-cyclodextrin (CMCD) solid in 100 mL to remove CO 2 After the deionized water is transferred to the four-necked bottle, then add the hydrotalcite precursor NO which is filled with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com