Machine-made sand plastering mortar additive

A plastering mortar and admixture technology, applied in the field of building materials, can solve the problems of poor workability of machine-made mortar, hollowing and cracking of mortar, and achieve the effects of inhibiting hollowing and cracking, reducing water-cement ratio and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below by embodiment, the present invention will be further described. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0021] A special mortar additive for machine-made sand, which is formulated according to the following weight percentages: hydroxypropyl methylcellulose ether: 15%; starch ether: 30%; redispersible latex powder: 30%; air-entraining agent: 5%; Polycarboxylate superplasticizer: 20%, weighed according to the proportion, add it into the gravity-free mixer in a certain order and stir, stir and mix for 15 minutes, and release the material to pack the finished admixture.

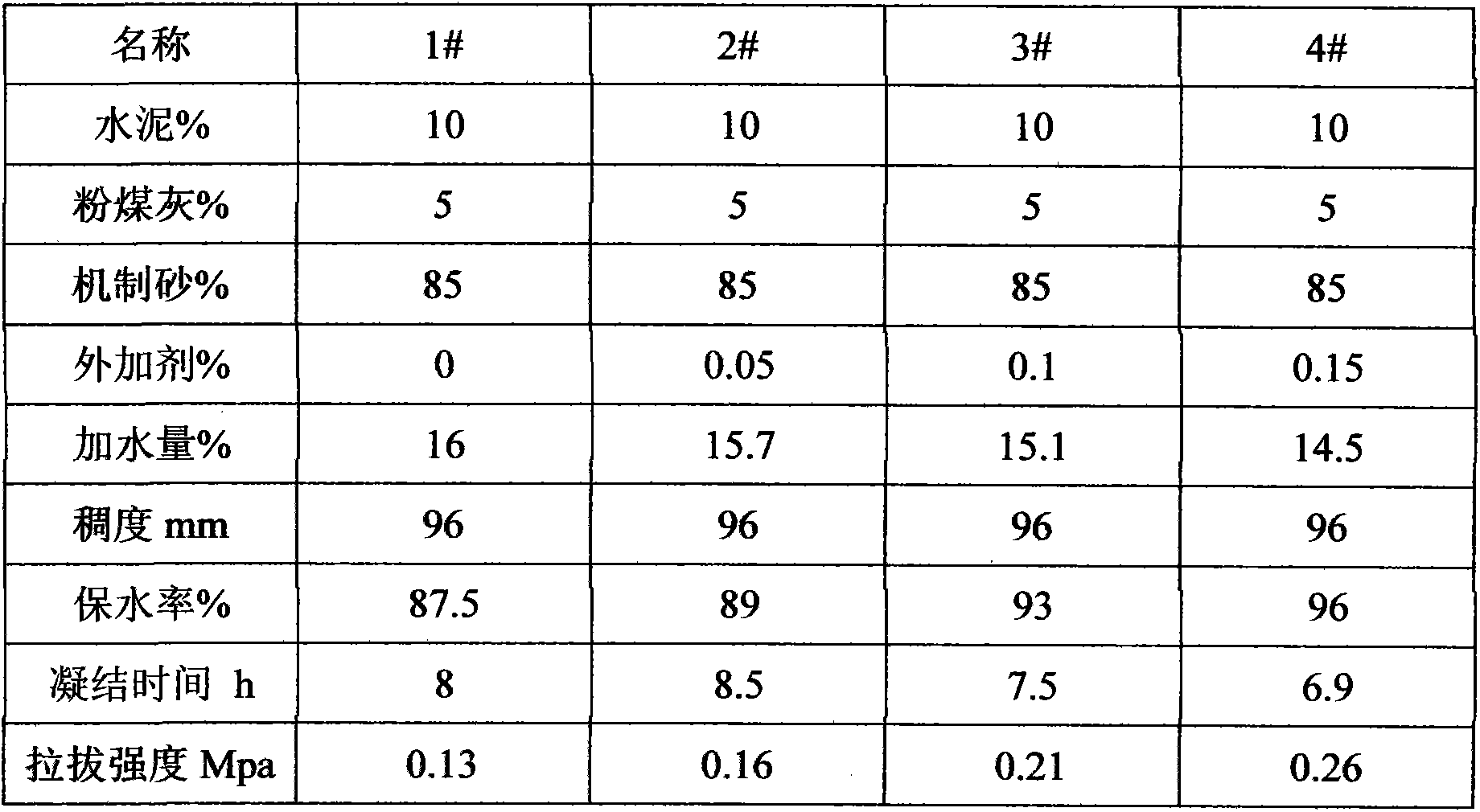

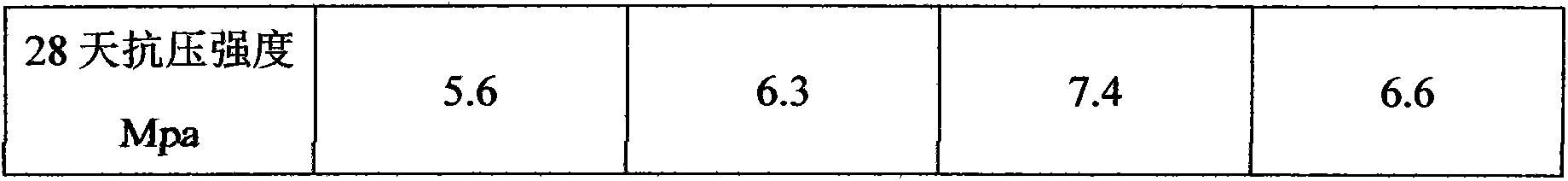

[0022] The percentage of mortar ingredients and main physical and chemical indicators added with the above-mentioned special mortar admixture for machine-made sand are as follows:

[0023]

[0024]

[0025] 1# is the mortar sample without admixture, 2#, 3# and 4# are the mortar samples mixed with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com