Composite aggregate planting concrete with decontamination function and preparation method of composite aggregate planting concrete

A kind of planting concrete and concrete technology, applied in the field of planting concrete, can solve the problems of non-purified water quality, achieve the effect of reducing transportation costs, flexible application, and suitable for large-scale production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] ① Raw materials: Yangzhou Lvyang brand 42.5 ordinary Portland cement is used for cement, and its performance index meets the requirements of GB175-2007 "General Portland Cement"; Zeolite powder is selected from Gongyi, Henan, and processed by a grinding machine. Its fineness is 80 μm square hole sieve ≤ 10% or 45 μm square hole sieve ≤ 30%; crushed stone adopts ordinary crushed stone with a particle size of 20~30 mm and a single particle size, and its performance index meets JGJ52-2006 " Standards for the Quality and Inspection Methods of Sand and Stone for Ordinary Concrete” stipulates that the ceramsite is selected from the clay ceramsite with a particle size of 10mm produced by Zhejiang Huzhou Xinxiang Ceramic Products Co., Ltd., and its performance indicators conform to GBT17431.1-2010 "Test Method" provisions;

[0025] ② Weigh raw materials according to the following parts by mass:

[0026] 1.00 parts of cement, 0.11 parts of zeolite powder, 0.42 parts of gravel, ...

Embodiment 2

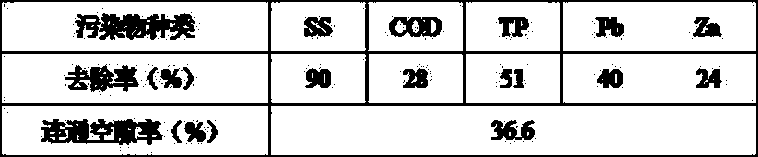

[0032] 1. Raw materials, 3. preparation, 4. decontamination effect test are the same as in Example 1

[0033] ② Weigh raw materials according to the following parts by mass:

[0034] 1.00 parts of cement, 0.11 parts of zeolite powder, 1.15 parts of gravel, 1.72 parts of ceramsite, 0.07 parts of water

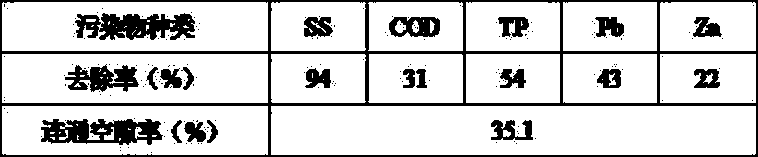

[0035] ⑤Test results:

[0036]

Embodiment 3

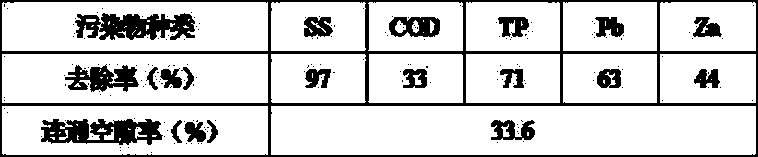

[0038] 1. Raw materials, 3. preparation, 4. decontamination effect test are the same as in Example 1

[0039] ② Weigh raw materials according to the following parts by mass:

[0040] 1.00 parts of cement, 0.11 parts of zeolite powder, 2.17 parts of gravel, 1.46 parts of ceramsite, 0.15 parts of water

[0041] ⑤Test results:

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com