Al2O3-TiN porous ceramic material and preparation method thereof

A technology of al2o3-tin and porous ceramics, applied in the field of material science, can solve the problems of unfavorable promotion and application of composite materials, complex equipment and process, low production efficiency, etc., and achieve the effect of novel concept, easy large-scale production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

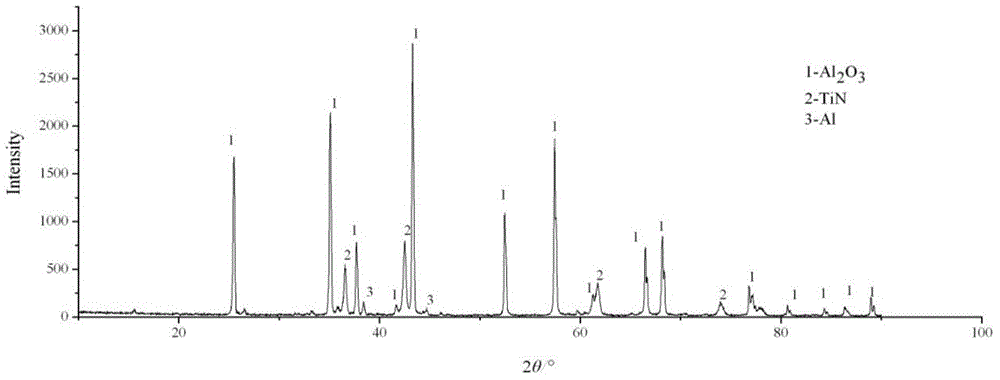

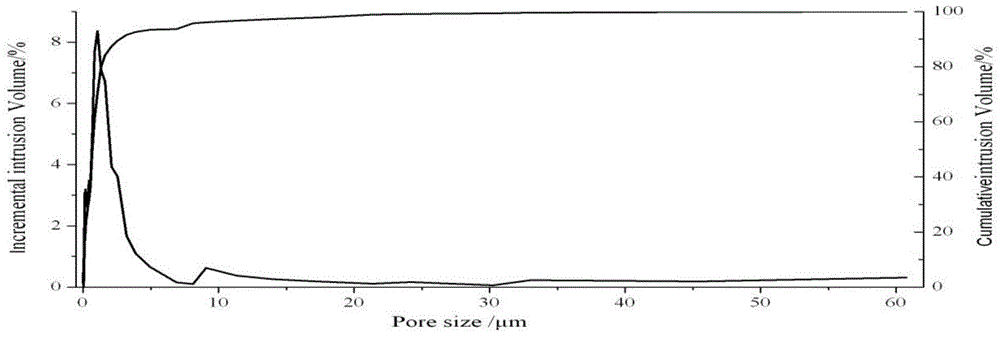

[0028] The technical scheme of the present invention provides an Al 2 o 3 -TiN porous ceramic material, the Al 2 o 3 - The TiN porous ceramic material consists of raw materials in the following weight ratios: Al 2 o 3 Coarse particle 15%, Al 2 o 3 Fine particle 45%, α-Al 2 o 3 Micropowder 30.54%, TiO 2 Micro powder 6.53%, Al powder 2.93%. The Al 2 o 3 The diameter of the coarse particle is 1mm; the Al 2 o 3 The fine particles have a diameter of 0.5 mm. The α-Al 2 o 3 Micronized D 50 The median particle size is 9.42 μm; the TiO 2 The average particle size of the fine powder is 0.5 μm; the D of the Al powder 50 The median particle size is 38.28 μm.

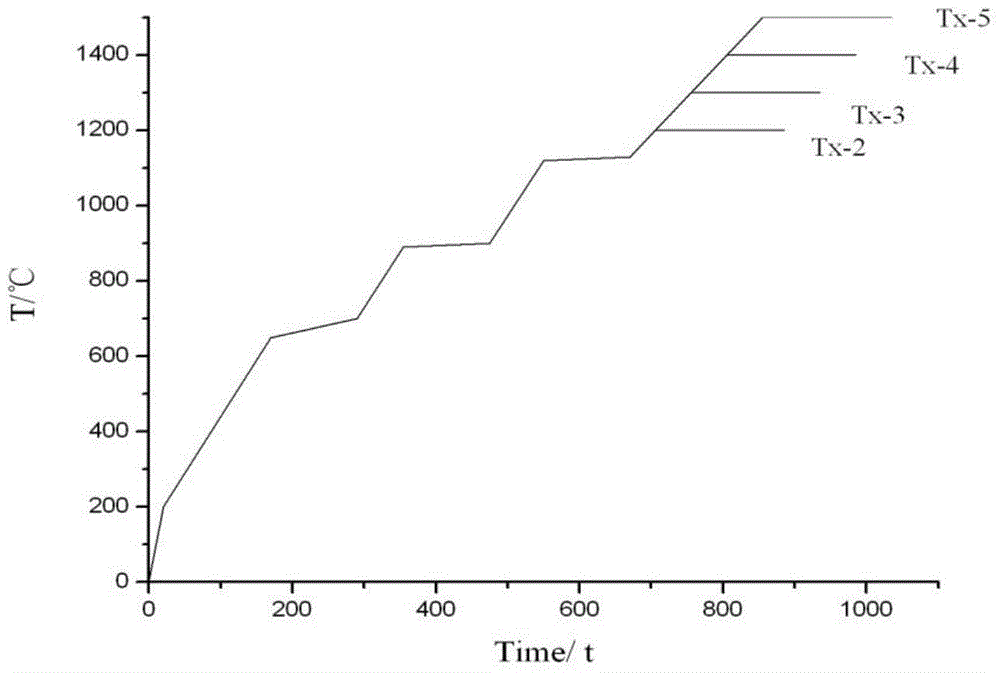

[0029] Preparation of Al 2 o 3 -A method for a TiN porous ceramic material, comprising the steps of:

[0030] (1) α-Al 2 o 3 、TiO 2 , Al various fine powders are put into the nylon ball milling tank according to the required ratio, the ball milling medium is corundum ball, and the material: ball ratio is 1:2...

Embodiment 2

[0035] The technical scheme of the present invention provides an Al 2 o 3 -TiN porous ceramic material, the Al 2 o 3 - The TiN porous ceramic material consists of raw materials in the following weight ratios: Al 2 o 3 Coarse particle 15%, Al 2 o 3 Fine particle 45%, α-Al 2 o 3 Micropowder 20.86%, TiO 2 Micro powder 13.20%, Al powder 5.94%. The Al 2 o 3 The diameter of the coarse particle is 0.8mm; the Al 2 o 3 The fine particles have a diameter of 0.3 mm. The α-Al 2 o 3 Micronized D 50 The median particle size is 8 μm; the TiO 2 The average particle size of the fine powder is 1 μm; the D of the Al powder 50 The median particle size is 15 μm.

[0036] Preparation of Al 2 o 3 -A method for a TiN porous ceramic material, comprising the steps of:

[0037] (1) α-Al 2 o 3 、TiO 2 , Al various fine powders are put into the nylon ball mill tank according to the required ratio, the ball milling medium is corundum balls, take out after dry mixing, and Al 2 o 3 ...

Embodiment 3

[0042] The technical scheme of the present invention provides an Al 2 o 3 -TiN porous ceramic material, the Al 2 o 3 - The TiN porous ceramic material consists of raw materials in the following weight ratios: Al 2 o 3 Coarse particle 15%, Al 2 o 3 Fine particle 45%, α-Al 2 o 3 Micropowder 10.95%, TiO 2 Micro powder 20.04%, Al powder 9.01%. The Al 2 o 3 The diameter of the coarse particle is 0.8mm; the Al 2 o 3 The fine particles have a diameter of 0.3 mm. The α-Al 2 o 3 Micronized D 50 The median particle size is 8 μm; the TiO 2 The average particle size of the fine powder is 1 μm; the D of the Al powder 50 The median particle size is 15 μm.

[0043] Preparation of Al 2 o 3 -A method for a TiN ceramic composite comprising the steps of:

[0044] (1) α-Al 2 o 3 、TiO 2 , Al various fine powders are put into the nylon ball mill tank according to the required ratio, the ball milling medium is corundum balls, take out after dry mixing, and Al 2 o 3 Coarse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com