Preparation method for 1-heptene

A technology of heptene and ethylene, applied in the field of preparation of 1-heptene, achieves the effects of controlled reaction conditions, high activity, and simple and easy-to-operate preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

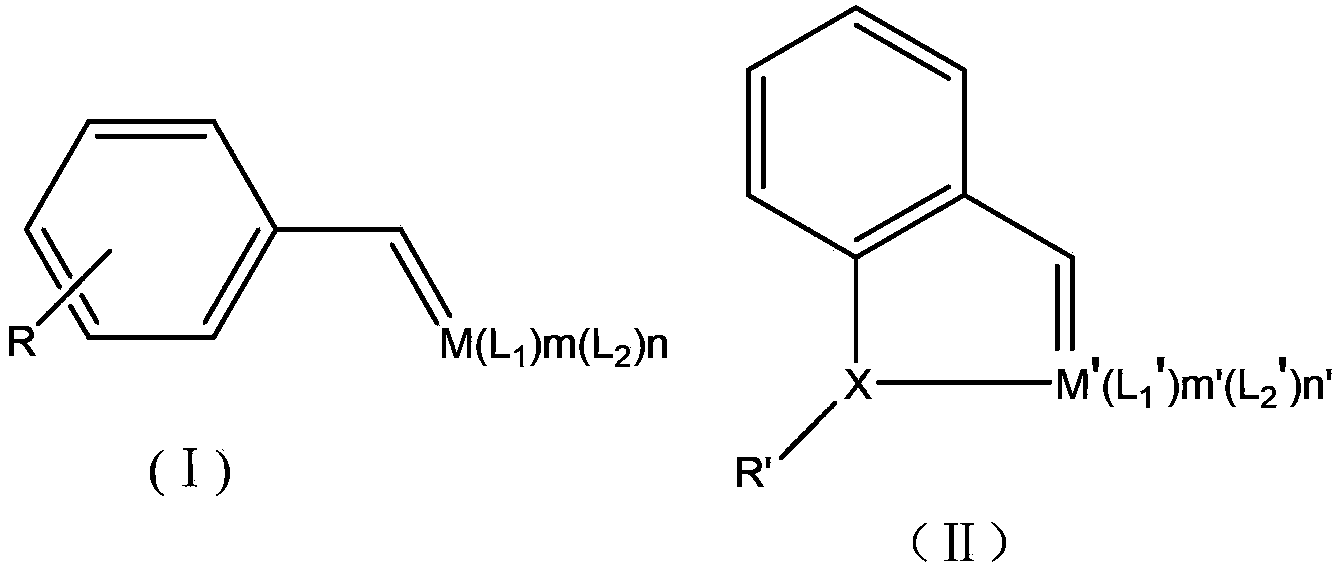

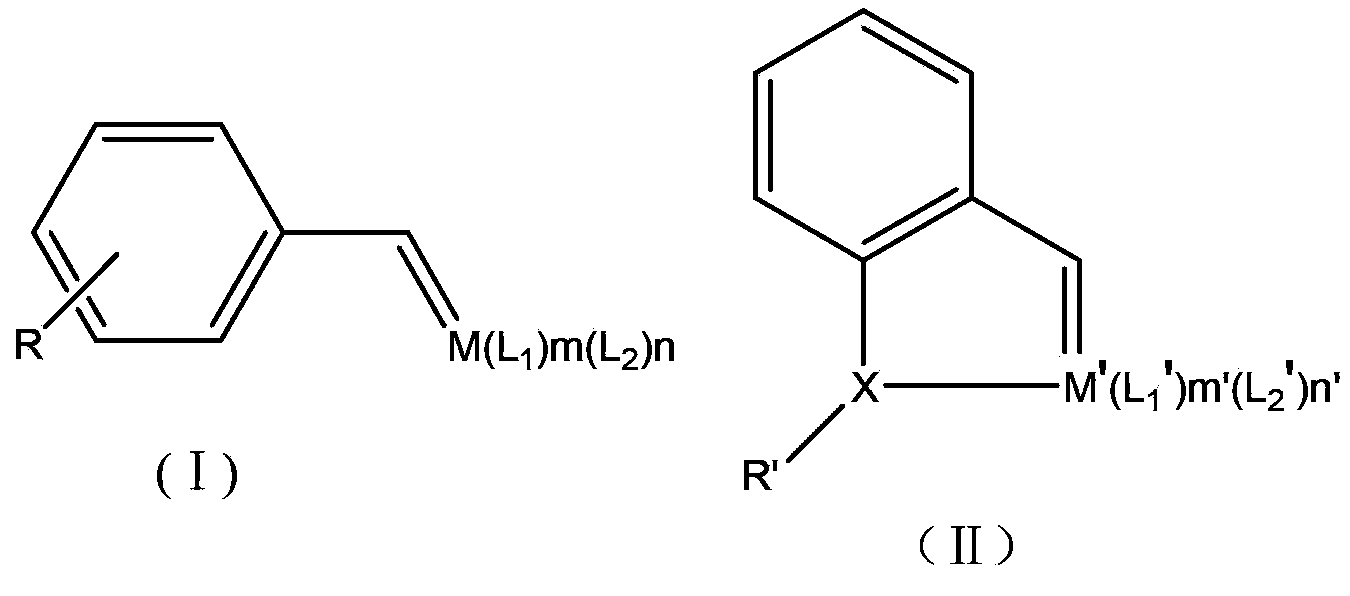

[0030] In the glove box under inert atmosphere, according to the molar ratio of 2-octene and ruthenium catalyst is 4500:1, the 2-octene of 4.26ml is dissolved in the toluene of 26ml, 5mg ruthenium catalyst A (catalyst 1 is formula I The catalyst of the structure, wherein R is H, M is metal ruthenium, L 1 is chlorine, L 2 It is tricyclohexylphosphine, m and n are both 2) dissolved in 20ml of toluene, respectively added to two glass syringes, sealed and taken out from the glove box. The reaction device adopts a 100ml autoclave reaction device. Heat the autoclave to 30°C, vacuumize and replace it with ethylene several times, open the vent valve, then quickly add 2-octene into the reaction kettle, and then add the ruthenium catalyst into the reaction kettle. Then close the vent valve, pre-mix and stir for 2 minutes, set the pressure at 0.5 MPa, feed ethylene into it for reaction, and the reaction time is 0.5 h. After the reaction is completed, the liquid phase product is collec...

Embodiment 2

[0032] The experimental method is the same as in Example 1, the reaction temperature is changed to 40°C, and the remaining experimental conditions are unchanged. The test reaction results are as follows: 1-heptene yield: 91.3%, 2-octene conversion rate: 76.5%, selectivity: 80.1 %, catalyst activity: 8.61×10 5 g / mol·Ru·h. Please refer to Table 1 for details.

Embodiment 3

[0034] The experimental method is the same as in Example 1, the reaction time is changed to 10min, and all the other experimental conditions are unchanged. The test reaction results are as follows: 1-heptene yield: 81.7%, 2-octene conversion rate: 44.9%, selectivity: 71.5% , catalyst activity: 4.66×10 5 g / mol·Ru·h. Please refer to Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com