A supported non-metallocene catalyst for ethylene polymerization

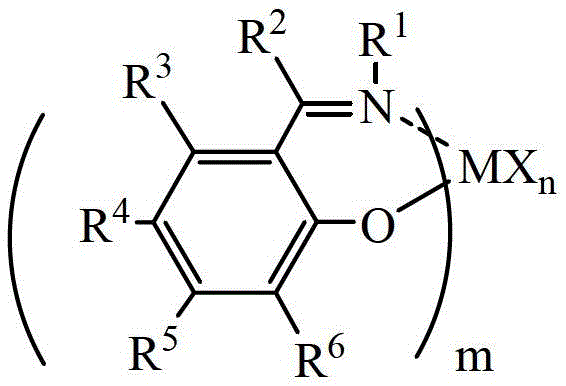

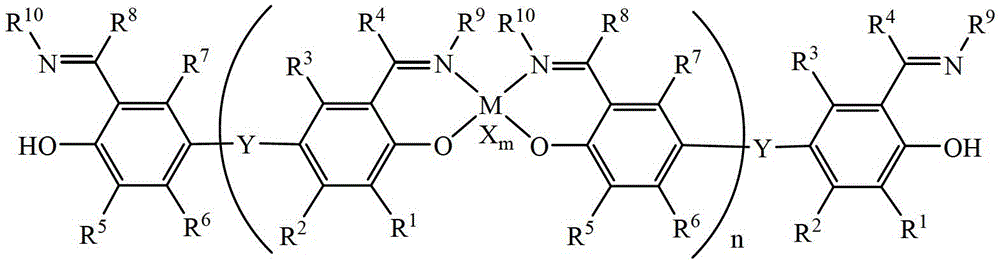

A non-metallocene and ethylene polymerization technology is applied in the field of supported non-metallocene catalysts, which can solve the problems of complex preparation methods of supported catalysts, complicated preparation of supports, and limited industrial applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0183] (1) Preparation of chlorinated hydrocarbyl silicon / magnesium chloride support

[0184] Under the protection of nitrogen, take 5.00 g of magnesium chloride carrier and add 60 ml of dried hexane to disperse into a suspension, add 1 ml of SiCl 2 (n-Bu) 2 , start stirring, heat up to 30° C., react for 4 hours, and dry in vacuum to obtain a solid powder with good fluidity.

[0185] (2) Preparation of alkyl aluminoxane / chlorinated hydrocarbyl silicon / magnesium chloride support

[0186] Under nitrogen protection, take 5.0 grams of the modified magnesium chloride carrier obtained above and add it to a glass reactor, add 60 milliliters of dried toluene, disperse into a suspension, and add 18 milliliters of 10 wt% MAO (methylaluminoxane) toluene solution , heated to 50 ° C, stirred for 4 hours, then washed three times with 50 ml × 3 toluene, then washed with hexane, and dried in vacuum to obtain a solid powder with good fluidity, that is, a magnesium chloride carrier containing...

Embodiment 2

[0196] (1) Preparation of chlorinated hydrocarbyl silicon / magnesium chloride support

[0197] With embodiment 1 step (1), only SiCl in embodiment 1 2 (n-Bu) 2 Change to SiCl 4 .

[0198] (2) Preparation of alkyl aluminoxane / chlorinated hydrocarbyl silicon / magnesium chloride support

[0199] Same as step (2) of Example 1.

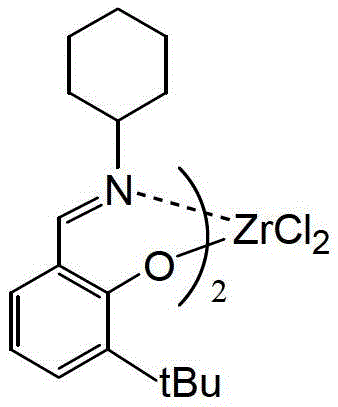

[0200] (3) Preparation of supported non-metallocene catalyst B

[0201] Same as step (4) of Example 1, only 0.168 grams of [bis-[N-(3-tert-butyl-o-hydroxybenzylidene) cyclohexylamine] zirconium dichloride] in Example 1 was replaced by 0.152 grams 【Bis-[N-(3-tert-butyl-o-hydroxybenzylidene) aniline] titanium dichloride】(L 2 ) 2 TiCl 2 (See below for its structure, see literature for its synthesis, Chemistry Letters, 1999, 1065), and obtain a supported non-metallocene catalyst B. Characterized by ICP, in catalyst B, the weight content of Ti is 0.33%, and the weight content of Al is 11.48%.

[0202]

Embodiment 3

[0204] (1), (2) are the same as the preparation methods of (1) and (2) in Example 2.

[0205] (3) Preparation of supported non-metallocene catalyst C

[0206] Same as step (3) of Example 1, only 0.168 grams of [bis-[N-(3-tert-butyl-o-hydroxybenzylidene) cyclohexylamine] zirconium dichloride] in Example 1 was replaced by 0.198 grams 【Bis-[N-(3-phenyl-o-hydroxybenzylidene) aniline] titanium dichloride】(L 3 ) 2 TiCl 2 (Its structure sees below), and its synthesis sees literature Chemistry Letters, 1999, 1065), obtains supporting non-metallocene catalyst C. Characterized by ICP, the weight content of Ti in catalyst C is 0.34%, and the weight content of Al is 11.32%.

[0207]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com