Film for electronic components

A technology of electronic components and film, applied in conductive adhesives, non-polymer adhesive additives, film/sheet adhesives, etc., can solve the problem of high heat dissipation requirements of electronic components and unimaginable heat dissipation effect. It is difficult to apply to specific use occasions and other problems, so as to achieve the effect of being conducive to heat dispersion and transmission, improving antistatic effect and good antistatic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

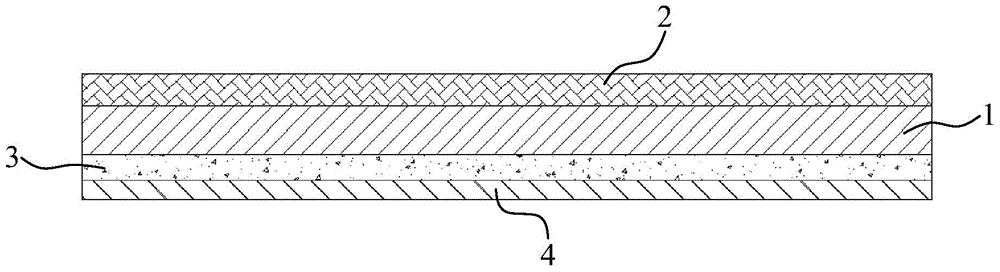

[0038] Embodiment: a film for electronic components, including PET film, the lower surface of the PET film is coated with a thermally conductive adhesive layer, a release paper is pasted on the other surface of the thermally conductive adhesive layer, and the thermally conductive adhesive layer Adhesive layer is made up of following components by weight:

[0040] Silicone 95,

[0041] Crosslinker 0.3,

[0042] Multifunctional acrylate monomer 70,

[0043] Initiator 0.7,

[0044] Solvent 50~300;

[0045] The organosilicon is an alkyl silanol conforming to the general formula (1),

[0046] (1);

[0047] In the formula, R represents an alkyl group with 3 to 8 carbon atoms, and n is greater than or equal to 1;

[0048] The crosslinking agent is selected from compounds of the following general formula (2),

[0049]

[0050] (2);

[0051] In the formula, R 1 , R 2 , R 3 Each independently represents the residue after removing one hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com