Lactobacillus combined starter culture for fermenting soybean milk

A technology of fermenting soybean milk and combined fermentation, applied in the direction of microorganism-based methods, bacteria, applications, etc., can solve the problems of uneasy flavor, listing, and large-scale products that have not yet been formed, and achieve the effect of delicate taste and easy acceptance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

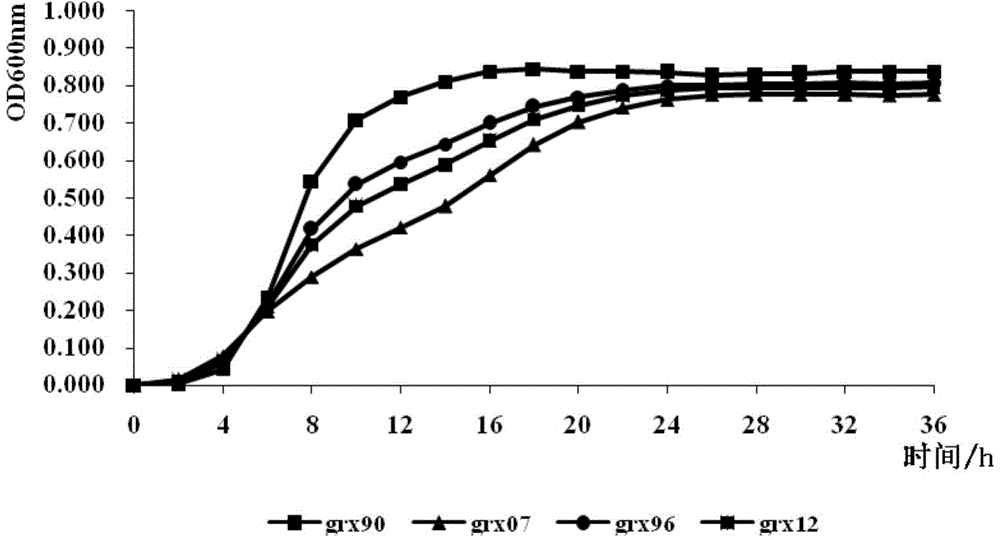

[0074] Weigh 100kg of impurity-removed soybeans, soak them in 3 liters of 0.5% (w / v) NaHCO after boiling them in water at 100°C for 3 minutes 3 In the solution for 12 hours, wash the soybeans and scald them with 90°C hot water for 2 minutes, then use 700 liters of 85°C hot water for grinding, mix the ground soybean milk and bean dregs, finely grind them through a colloid mill, and filter the bean dregs through a 100-mesh sieve. soy milk. After the raw milk is standardized, weigh 300 liters and mix it with 700 liters of soybean milk, add 7.5kg of sucrose and 0.81kg of whey powder, homogenize at 20MPa, heat treat at 90-95°C for 15 minutes, cool to 42°C, inoculate with Streptococcus thermitis grx90, Lactobacillus fermentum grx07, Lactobacillus helveticus grx96 and Lactobacillus casei grx12 were mixed with 10 liters of starter, fermented at 42°C until the curdled milk was refrigerated for 24 hours at 4°C to make 1000 liters of fermented soybean milk.

Embodiment 2

[0076] Whole milk powder is reconstituted with a mass fraction of 12%. Weigh 300 liters and mix it with 700 liters of soybean milk prepared in Example 1. Add 8 kg of sucrose and 0.6 kg of whey powder. Homogenize at 20 MPa, 90- Heat treatment at 95°C for 15 minutes, then cool to 42°C, inoculate 10 liters of starter mixed with Streptococcus thermophilus grx90, Lactobacillus fermentum grx07, Lactobacillus helveticus grx96 and Lactobacillus casei grx12, ferment at 42°C until curdled at 4°C Refrigerate for 24 hours to make 1000 liters of fermented soybean milk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com