Smelting method of high-alloy steel with content of Mn being 8.0%

A high-alloy steel and smelting method technology, applied in the field of metallurgy, can solve the problems affecting stainless steel production capacity, occupying stainless steel production resources, producing continuous casting billets, etc., so as to shorten melting time and refining production time, shorten refining production time, and improve alloying. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Produce a furnace of high-alloy steel with a manganese content of 8.0%, with a cross-section of 220*1060mm. The adopted process route includes the following procedures: hot metal pretreatment - steelmaking using converter + intermediate frequency furnace - LF refining - RH vacuum refining - continuous casting machine.

[0029] The pretreatment process is the same as the existing steelmaking pretreatment;

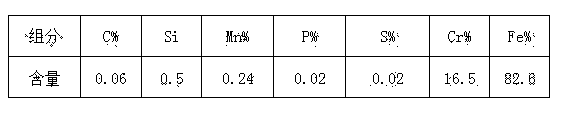

[0030] Converter smelting adopts full molten iron smelting without adding scrap steel; the temperature of tapping from the converter is 1659°C; the temperature after the furnace is 1597; 0.016, Mo is 0.397, V is 0.25, and the balance is iron and unavoidable impurities;

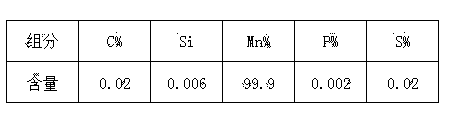

[0031] Intermediate frequency furnace smelting and adding 7.2 tons of chromium alloy, 4 tons of low-phosphorus manganese alloy and 3 tons of high-phosphorus manganese alloy; the temperature of the alloy solution after mixing the alloy is 1536 °C; the mass percentage of the chemical composition of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com