A kind of wiping agent and preparation method thereof for removing carbon deposits in gun inner chambers

A wiping agent and carbon deposition technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of poor effect, time-consuming and labor-intensive, etc., and achieve low production cost, accelerated mixing and good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

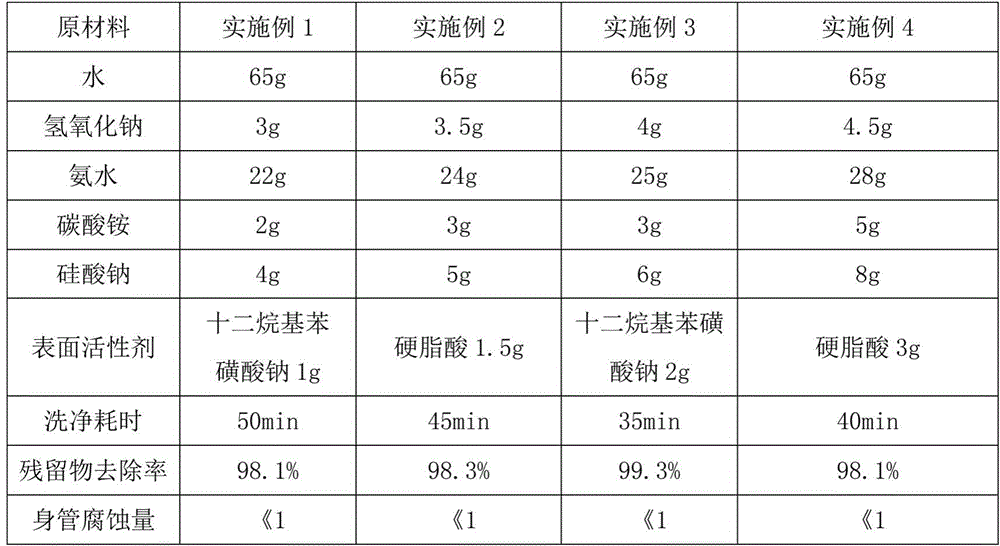

Examples

Embodiment 1

[0023] A wiping agent for removing carbon deposits in the gun bore, which is made of the following raw materials: water, sodium hydroxide, ammonia water, ammonium carbonate, sodium silicate, sodium dodecylbenzenesulfonate, the specific raw material ratio See Table 1.

[0024] Concrete preparation method is:

[0025] 1) Weigh each raw material according to the proportion, and divide the water into three parts;

[0026] 2) Pour the ammonia water into one part of the water slowly and uniformly along the inner wall of the container, and stir while adding to obtain the ammonia solution;

[0027] 3) Grind ammonium carbonate, sodium silicate, sodium hydroxide and sodium dodecylbenzenesulfonate, sieve, then pour the under-sieve into another part of water, dissolve and stir evenly, then pour into step 2 ) in the prepared solution, mix;

[0028] 4) Slowly and uniformly pour the remaining portion of water into the solution prepared in step 3) along the inner wall of the container, mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com