Direct pressure pipe coating scratch resistance performance tester

A scratch-resistant, direct-pressure technology, applied in testing wear resistance, etc., can solve problems such as unsatisfactory performance and no description of test instruments, and achieve the effects of low cost, accurate and stable pressure, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

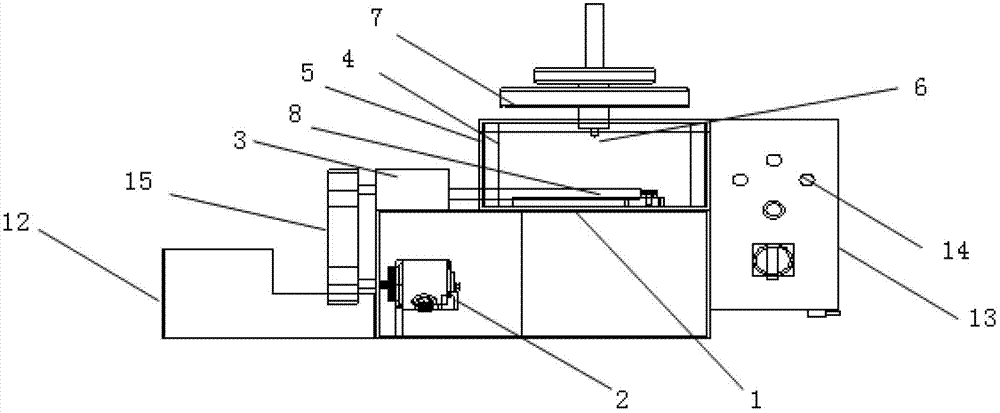

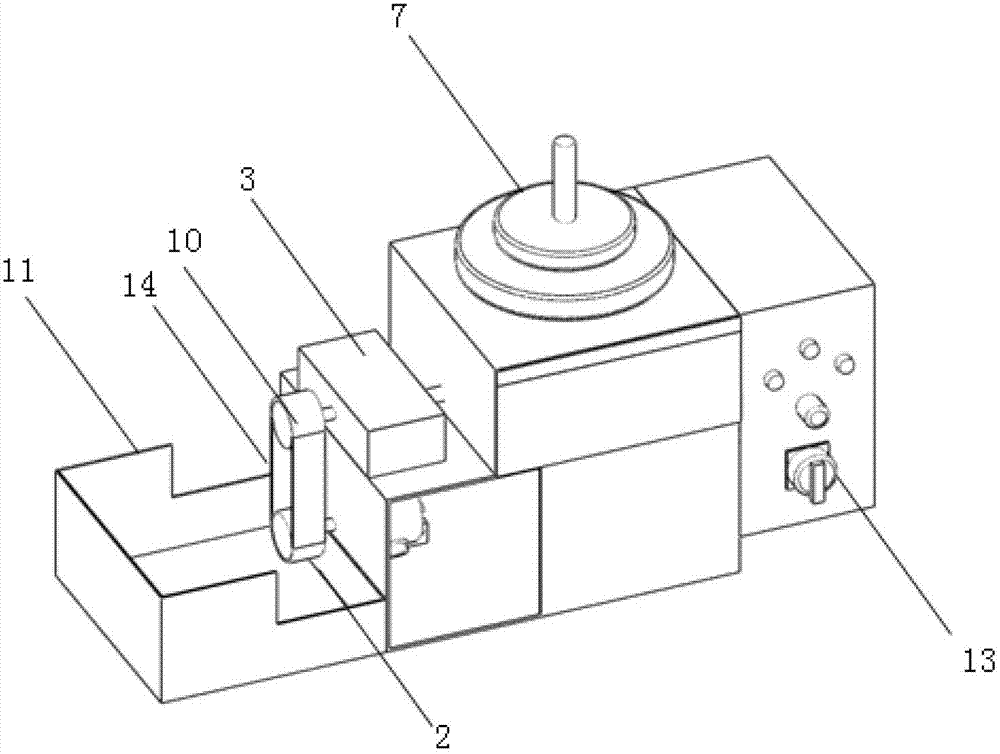

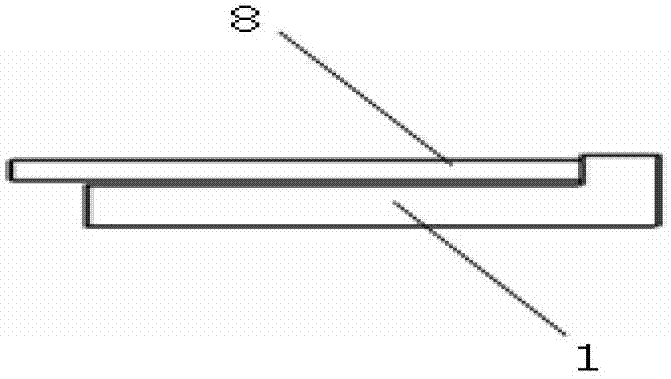

[0038] Embodiment. The specific embodiment of the present invention is described with this example and the present invention is described further. This example is an experimental prototype, its composition is as follows Figure 1-Figure 4 shown. Including test platform 1, stepper motor and coupling 2, test sliding table 3, pneumatic support 4, support frame 5, pressure sensor and scratch probe fixing block 6, counterweight 7, guide rail 8, screw 9, coupling Device 10 and metal mesh shield 11, control box 12, control button 13, pulley 14. Stepper motor and coupling 2. The test sliding table is installed on one side of the test platform 1, the control part is installed on the other side of the test platform 1, the loading mechanism 7 is installed on the middle top of the test platform 1, and the scratch probe is installed on the The lower top of the iron rod in the counterweight loading mechanism 7.

[0039] The main dimensions of the mechanical part are as follows:

[0040] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com