Preparation method of methacrylic acid bentonite

A technology of methacrylic acid and methacrylic acid ethanol, which is applied in the field of preparation of methacrylic acid bentonite, can solve problems such as irregular distribution, achieve uniform reaction, prevent self-aggregation, and increase organic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Alkaline calcium-based bentonite: methacrylic acid bentonite: ethanol: a certain mass ratio of cyclohexane is mixed step by step, the alkaline earth is placed in a three-necked flask, and 2 / 3 of the total amount of cyclohexane added is added to the three-necked flask. Use 100W ultrasonic power to ultrasonically disperse at room temperature for 10 minutes; after the ultrasonic dispersion is completed, place the three-neck flask in a water bath, stir and heat the magnetic particles in a constant temperature water bath at 80°C, and when the temperature is constant, drop methacrylic acid, The mixture of ethanol and the remaining cyclohexane was kept at a rate of 1 drop / s, and then reacted with water for 2 hours, the reactant was filtered by suction, dried at 105°C for 16 hours, and naturally cooled to room temperature to obtain the methacrylic acid bentonite , after scanning electron microscope image 3 , prepared a group of methacrylic acid bentonite without ultrasonic dis...

Embodiment 2

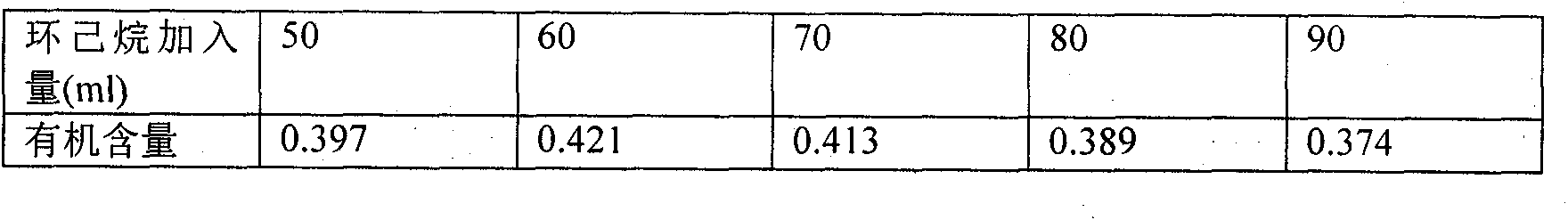

[0014] Alkaline calcium-based bentonite: methacrylic acid bentonite: ethanol: a certain mass ratio of cyclohexane is mixed step by step, the alkaline earth is placed in a three-necked flask, and 2 / 3 of the total amount of cyclohexane added is added to the three-necked flask. Use 100W ultrasonic power to ultrasonically disperse at room temperature for 10 minutes; after the ultrasonic dispersion is completed, place the three-neck flask in a water bath, stir and heat the magnetic particles in a constant temperature water bath at 80°C, and when the temperature is constant, drop methacrylic acid, The mixture of ethanol and the remaining cyclohexane was kept at a rate of 1 drop / s, and then reacted with water for 2 hours, the reactant was filtered by suction, dried at 105°C for 16 hours, and naturally cooled to room temperature to obtain the methacrylic acid bentonite . Under the same conditions, 50.60.70.80.90ml cyclohexane dispersant was used in this experiment to prepare methacryl...

Embodiment 3

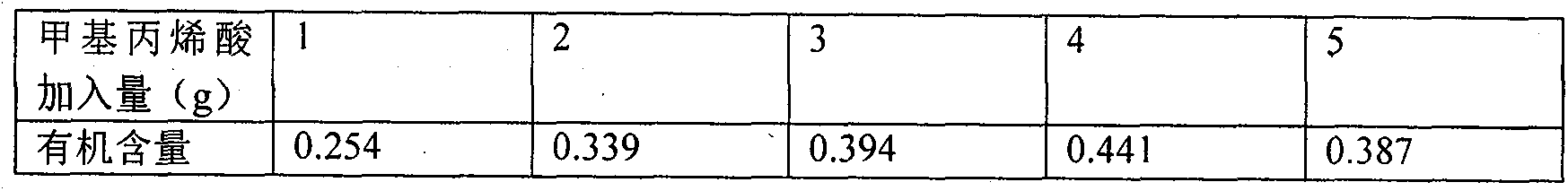

[0019] Basic calcium-based bentonite: ethanol: a certain mass ratio of cyclohexane is mixed step by step, the alkaline earth is placed in a three-necked flask, and 2 / 3 of the total addition of cyclohexane is added to the three-necked flask, and a 100W Ultrasonic dispersion with ultrasonic power for 10 minutes; after the ultrasonic dispersion, place the three-neck flask in a water bath, stir and heat the magnetic particles in a constant temperature water bath at 80°C, and when the temperature is constant, drop methacrylic acid, ethanol and the remaining ring The hexane mixture was kept at a rate of 1 drop / s, then condensed to separate water for 2 hours, the reactant was suction filtered, dried at 105°C for 16 hours, and naturally cooled to room temperature to obtain the methacrylic acid bentonite. Under the same conditions, 1 g, 2 g, 3 g, 4 g, and 5 g of methacrylic acid were used in this experiment to prepare methacrylic acid bentonite as shown in Table 2.

[0020] Table 2

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com