A kind of preparation technology of iron oxide black

A technology for the preparation of iron oxide black, which is applied in the field of pigment preparation, can solve the problems of poor tinting strength, long oxidation time, and many by-products of iron oxide black, and achieve the effects of strong coloring ability, reduced contact time, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

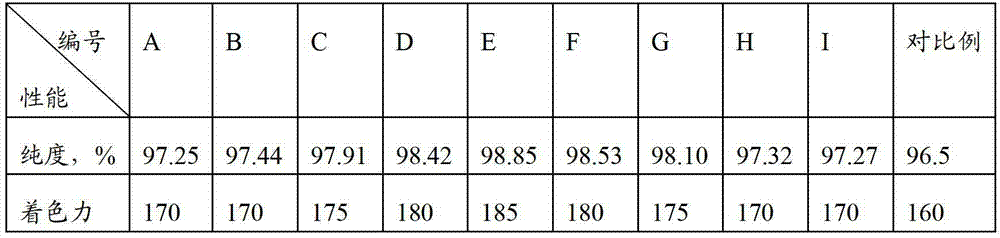

Examples

Embodiment 1

[0023] Iron oxide black preparation method described in the present embodiment is as follows:

[0024] (1) Dissolve 1.5kg of ferrous sulfate heptahydrate in water to obtain ferrous sulfate solution;

[0025] (2) Add 1.3kg of potassium hydroxide to the ferrous sulfate solution in the step (1), and carry out neutralization reaction at a temperature of 20°C until the pH value of the solution is constant;

[0026] (3) Warm up the solution after the neutralization reaction in step (2) to 80°C;

[0027] (4) Add 2.625kg of amorphous ferric oxyhydroxide to the heated solution in step (3), and use 28wt% ammonia water to control the pH value of the solution to 9 during the reaction;

[0028] (5) After the reaction is completed, filter and dry the filter cake at 50°C to prepare iron oxide black pigment A.

Embodiment 2

[0030] Iron oxide black preparation method described in the present embodiment is as follows:

[0031] (1) Dissolve 1.0kg of ferrous nitrate and 1.0kg of ferrous sulfate in water to obtain a mixed solution of ferrous nitrate and ferrous sulfate;

[0032] (2) Add 1.0kg of sodium hydroxide and 0.7kg of potassium hydroxide to the mixed solution in the step (1), and carry out neutralization reaction at a temperature of 25°C until the pH value of the solution is constant at 10;

[0033] (3) Warm up the solution after the neutralization reaction in step (2) to 80°C;

[0034] (4) Add 3.0 kg of amorphous ferric oxyhydroxide to the heated solution in step (3), and use 20 wt% sodium hydroxide solution to control the pH value of the solution to 9 during the reaction;

[0035] (5) After the reaction is completed, filter and dry the filter cake at 60°C to prepare iron oxide black pigment B.

Embodiment 3

[0037] Iron oxide black preparation method described in the present embodiment is as follows:

[0038] (1) Dissolve 2.3kg of ferrous chloride in water to obtain ferrous chloride solution;

[0039] (2) Add 2.2kg of potassium carbonate to the ferrous chloride solution in the step (1), and carry out neutralization reaction at a temperature of 30°C until the pH value of the solution is constant;

[0040] (3) Warm up the solution after the neutralization reaction in step (2) to 85°C;

[0041] (4) Add 3.7kg of amorphous ferric oxyhydroxide to the heated solution in step (3), and use 28wt% ammonia water to control the pH value of the solution to 11 during the reaction;

[0042] (5) After the reaction is completed, filter and dry the filter cake at 70°C to prepare iron oxide black pigment C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tinctorial strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com