MnZn ferrite material with high frequency and high impedance and preparation method thereof

A ferrite material and high impedance technology, applied in the field of MnZn ferrite material and its preparation, can solve the problems of low practical value, high impedance and low frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of high resistance MnZn ferrite material of the present invention comprises the following steps:

[0024] 1) The formula adopts 46.0-54.0mol% Fe 2 o 3 , 25.0-27.0mol% MnO and 19.0-21.0mol% ZnO;

[0025] 2) Mix the above-mentioned powders evenly, and perform ball milling for the first time;

[0026] 3) The powder obtained in step 2) is sprayed and granulated for the first time;

[0027] 4) Pre-burn the powder obtained in step 3) at 800°C-1000°C for 1-1.5 hours;

[0028] 5) Add auxiliary component 0.03wt%-0.08wt% TiO to the powder obtained in step 4) 3 , 0.03wt%-0.08wt% CaCO 3 , 0.03wt%-0.08wt% V 2 o 5 At least one of them, then add 60wt%-120wt% deionized water based on the total weight of the main components, 0.5wt%-3wt% dispersant, 0.5wt%-3wt% defoamer together for the second time Ball milling, so that the particle size of the powder after ball milling reaches 0.8-1 micron;

[0029] 6) Based on the total weight of the powder obtained in s...

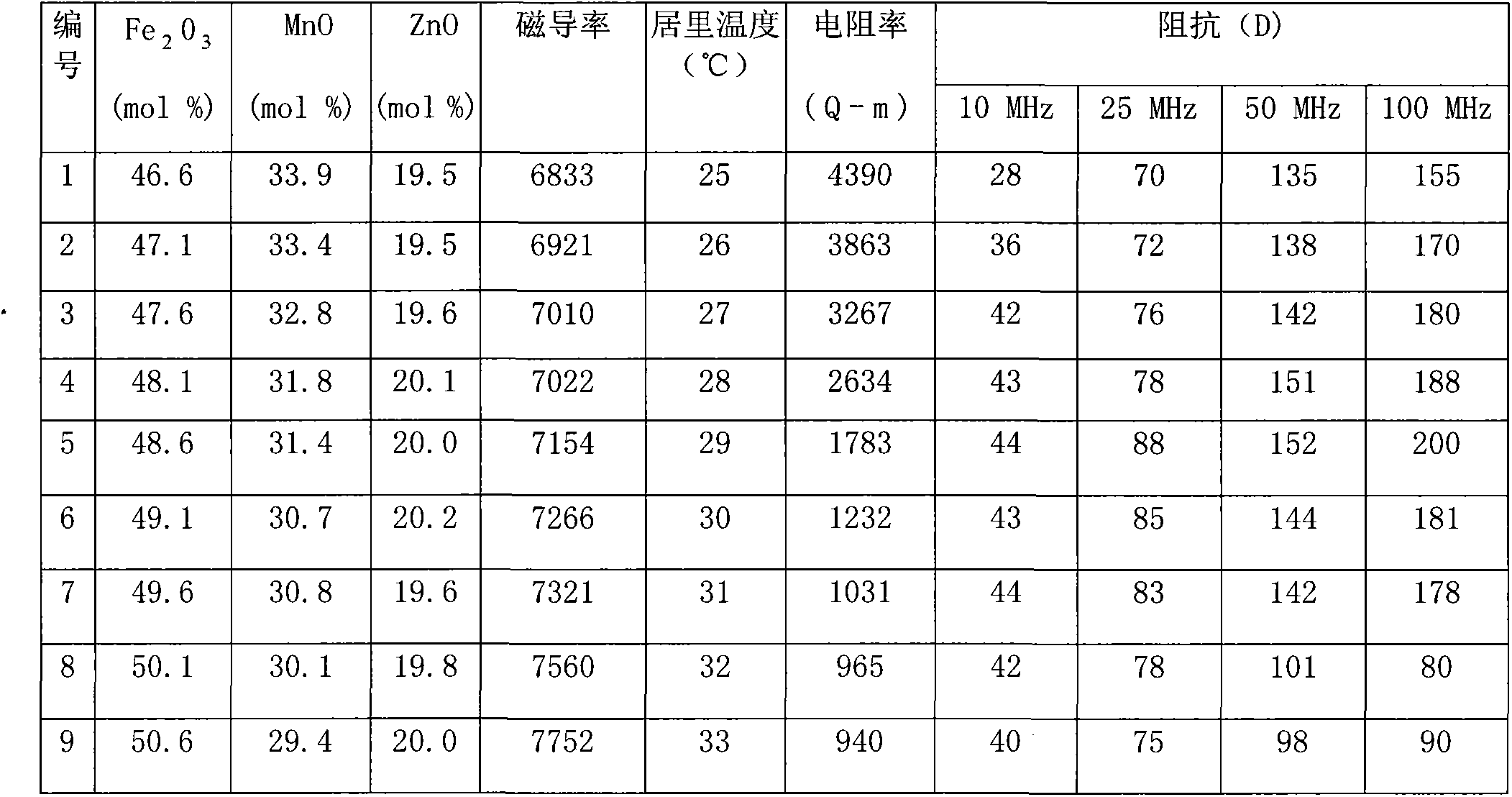

specific Embodiment 1-9

[0032] Specific embodiment 1-9 way: adopt commercially available Fe 2 o 3 , MnO, ZnO as the main component, 48.6mol% Fe 2 o 3 , 31.4mol% MnO, 20.0mol% ZnO are placed in a sand mill and stirred, mixed evenly, then taken out and dried in a drying oven; after drying, pre-burn at 800-900°C for 1.5h in a box-type resistance furnace . Then put the pre-fired powder into the ball mill, and add the auxiliary component 0.03wt% TiO 3 , 0.04 wt% CaCO 3 , and then add 60wt% deionized water, 2wt% dispersant, and 2wt% defoamer based on the total weight of the main components for ball milling; ball mill the powder until the average particle size is about 1.0±0.2mm, and dry Then add 8wt% polyvinyl alcohol aqueous solution based on the total weight of the powder to granulate, sinter at a sintering temperature of 1300°C-1400°C in a seed pressure hood furnace, and keep warm at the sintering temperature for 2-5 hours, Then it is cooled to 180°C and released from the furnace, wherein the oxyg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com