Bamboo powder bio-organic fertilizer and production method thereof

A bio-organic fertilizer and production method technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as fertility decline, crop quality deterioration, acidification, etc., to promote crop growth, reduce incidence, and inhibit harmful flora. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

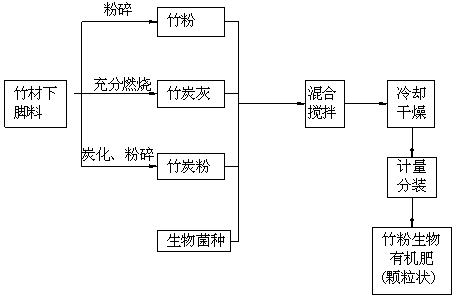

[0037] The selected bamboo or bamboo waste is cut off, dried naturally or artificially, then carbonized at high temperature, cooled and then pulverized by a pulverizer to obtain bamboo charcoal powder with a fineness of 80-100 mesh and a water content of 9% or less. Part of the bamboo charcoal continues to be heated at high temperature under aerobic conditions to obtain bamboo charcoal ash. The selected bamboo or bamboo waste is crushed and cut, dried naturally or artificially, and then crushed by a pulverizer, and then ground into a powder by a grinder to obtain bamboo powder with a fineness of 40-60 mesh and a water content of 6% or less. The biological strain is Bacillus subtilis.

[0038] The obtained bamboo charcoal powder, bamboo charcoal ash and bamboo powder, rice bran fermented material, biological strains and binder are accurately proportioned according to the raw material ratio in Table 1. The mixture is thoroughly mixed by a mixer, and granulated by a granulator t...

Embodiment 2

[0042] Except following process, other is as embodiment 1. The biological strain is EM bacteria.

[0043] The obtained bamboo charcoal powder, bamboo charcoal ash and bamboo powder, rice bran fermented material, biological strains and binder are accurately proportioned according to the raw material ratio in Table 2. The mixture is thoroughly mixed by a mixer to prepare the granular bamboo powder bio-organic fertilizer.

[0044] Table 2 Production formula of bamboo powder bio-organic fertilizer

[0045] raw material bamboo charcoal powder Bamboo charcoal gray bamboo powder rice bran fermented material Biological strain Attapulgite powder Proportion (kg) 70 70 736 40 4 80

Embodiment 3

[0047] Except following process, other is as embodiment 1. The biological strain is a mixed strain of Bacillus subtilis and lactic acid bacteria in a mass ratio of 2:1.

[0048] The bamboo charcoal powder, bamboo charcoal ash and bamboo powder obtained in Example 1 were accurately compounded with the rice bran fermented material, biological strains and binding agent according to the raw material ratio in Table 3. The mixture is thoroughly mixed by a mixer, and granulated by a granulator to prepare granular bamboo powder bio-organic fertilizer.

[0049] Table 3 Production formula of bamboo powder bio-organic fertilizer

[0050] raw material bamboo charcoal powder Bamboo charcoal gray bamboo powder rice bran fermented material Biological strain starch Proportion (kg) 50 50 764 70 6 60

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com