PVC (Polyvinyl Chloride) pipe and preparation method thereof

A PVC pipe material and PVC resin technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of limited improvement in impact resistance, and achieve the effects of improved impact resistance, high yield, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

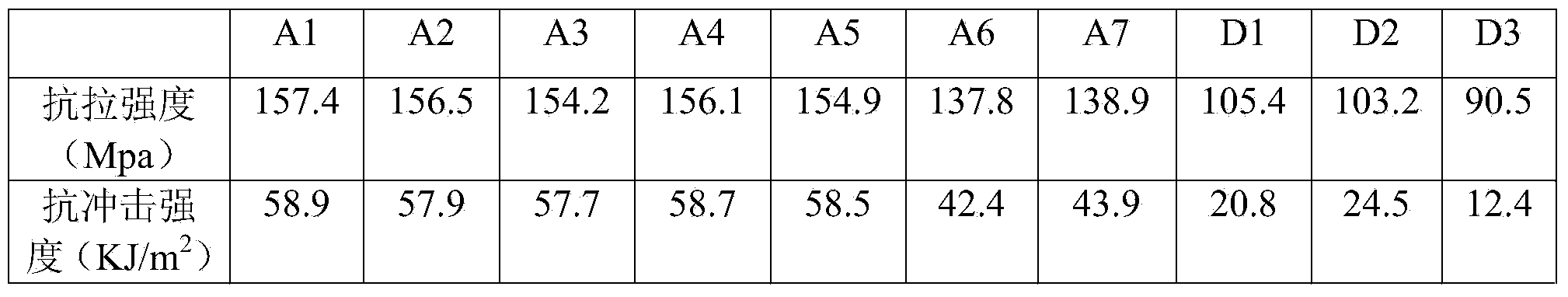

Embodiment 1

[0019] 100kg of PVC resin, 50kg of calcium carbonate, 15kg of CPE, 15kg of EPDM, 1.5kg of stearic acid, 2kg of titanium dioxide, 2kg of paraffin, 0.1kg of OB fluorescent whitening agent, 2.5kg of Calcium stearate, 2.5kg of zinc stearate and 1kg of PE wax were extruded at 170°C to prepare a PVC pipe A1 with a wall thickness of 4mm and an outer diameter of 160mm. Among them, the average degree of polymerization of PVC resin is 800, the weight average molecular weight of PE wax is 3000, the weight average molecular weight of CPE is 200,000, the weight average molecular weight of EPDM is 300,000, the particle size of calcium carbonate is 300 μm, the particle size of titanium dioxide is The diameter is 0.2 μm. A1 was tested for tensile strength and impact resistance, and the test results are shown in Table 1.

Embodiment 2

[0021] 100kg of PVC resin, 50kg of calcium carbonate, 15kg of CPE, 15kg of EPDM, 1.5kg of stearic acid, 2kg of titanium dioxide, 2kg of paraffin, 0.1kg of OB fluorescent whitening agent, 2.5kg of Calcium stearate, 2.5 kg of zinc stearate and 1 kg of PE wax were extruded at 170° C. to prepare a PVC pipe A2 with a wall thickness of 4 mm and an outer diameter of 160 mm. Among them, the average degree of polymerization of PVC resin is 720, the weight average molecular weight of PE wax is 2000, the weight average molecular weight of CPE is 200,000, the weight average molecular weight of EPDM is 200,000, the particle size of calcium carbonate is 130 μm, the particle size of titanium dioxide is The diameter is 0.3 μm. A2 was tested for tensile strength and impact resistance, and the test results are shown in Table 1.

Embodiment 3

[0023] 100kg of PVC resin, 50kg of calcium carbonate, 15kg of CPE, 15kg of EPDM, 1.5kg of stearic acid, 2kg of titanium dioxide, 2kg of paraffin, 0.1kg of OB fluorescent whitening agent, 2.5kg of Calcium stearate, 2.5 kg of zinc stearate and 1 kg of PE wax were extruded at 170° C. to prepare a PVC pipe A3 with a wall thickness of 4 mm and an outer diameter of 160 mm. Among them, the average degree of polymerization of PVC resin is 850, the weight average molecular weight of PE wax is 5000, the weight average molecular weight of CPE is 300,000, the weight average molecular weight of EPDM is 400,000, the particle size of calcium carbonate is 450 μm, the particle size of titanium dioxide is The diameter is 0.05 μm. A3 was tested for tensile strength and impact resistance, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com